Chicken feed and preparation method therefor

A chicken feed and barrel technology, which is applied in the field of chicken feed preparation, can solve the problems of uneven heating of pellet feed, affecting the quality of pellet feed, cracking of pellet feed, etc., and achieve the effects of preventing cracking, improving quality, and avoiding time waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

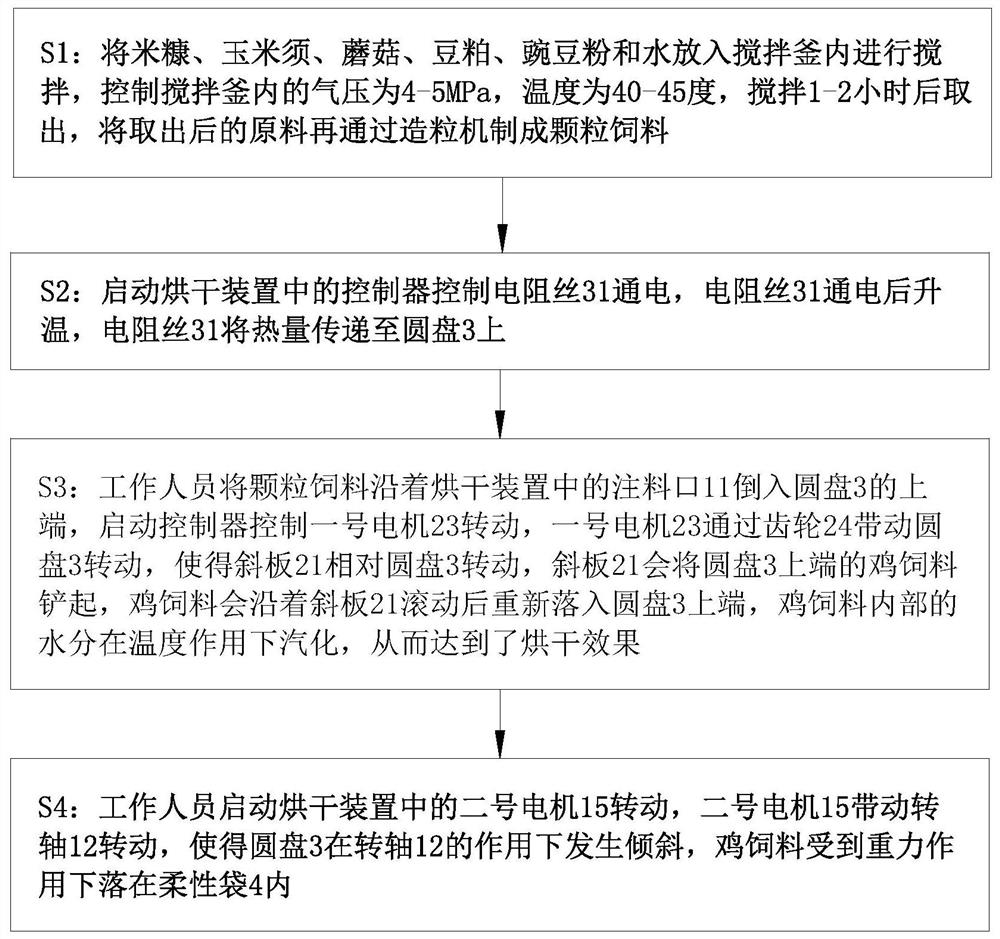

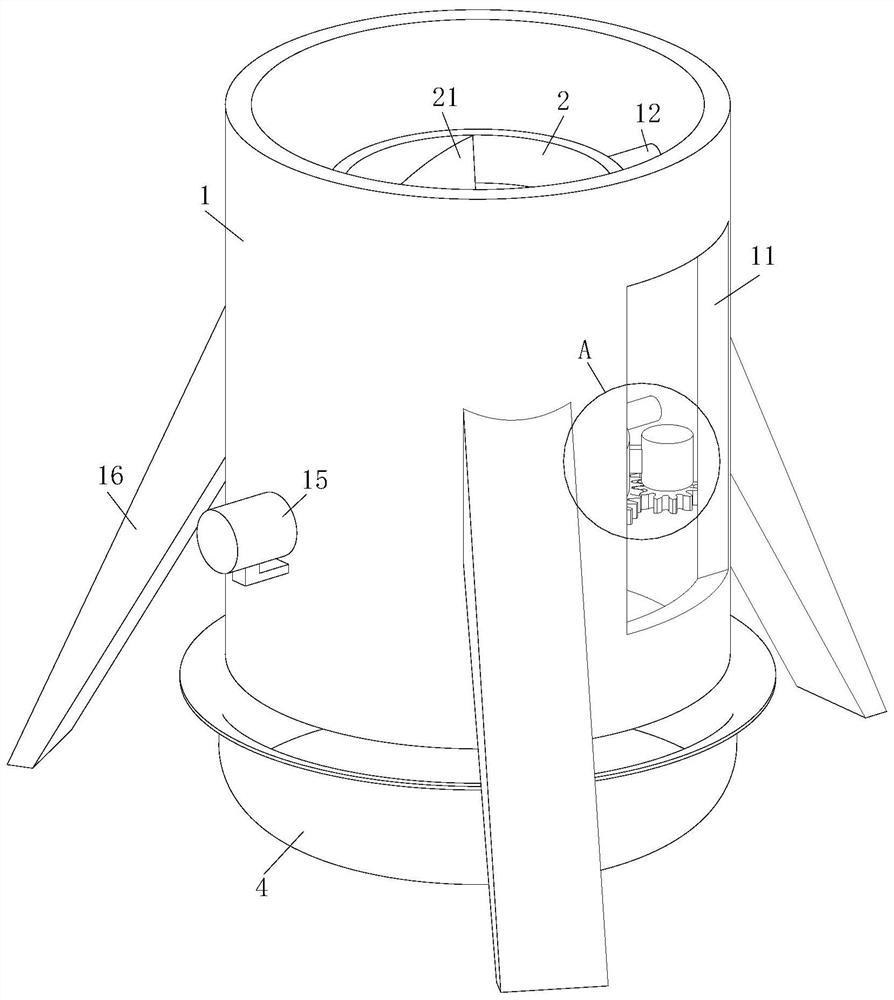

[0034] Such as Figure 1 to Figure 9 Shown, the preparation method of a kind of chicken feed of the present invention comprises the following steps:

[0035] S1: Put rice bran, corn silk, mushroom, soybean meal, pea powder and water into the stirring tank for stirring, control the air pressure in the stirring tank to 4-5MPa, the temperature to 40-45 degrees, stir for 1-2 hours and then take it out. The raw materials taken out are then passed through a granulator to make pellet feed; by controlling the air pressure in the stirring tank, the tightness between the particles is improved, so that the pellet feed made is not easy to loose, and the quality of chicken feed is improved;

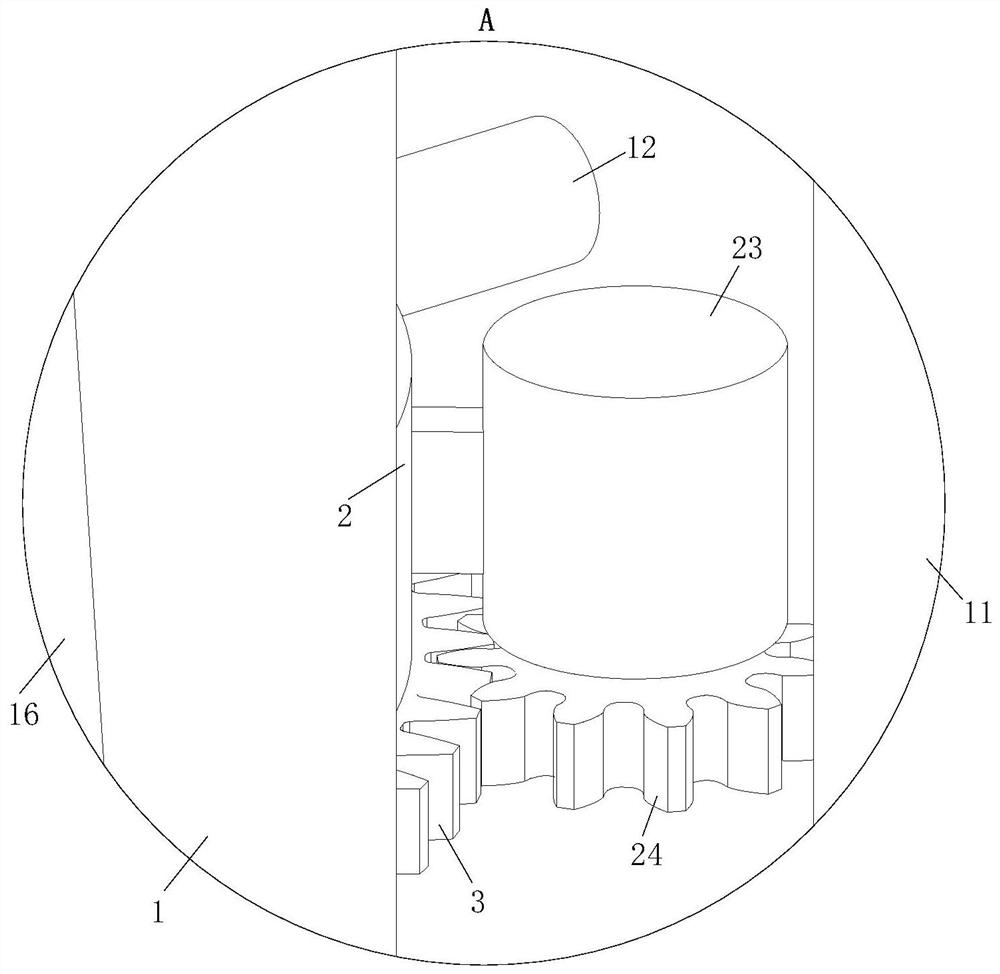

[0036] S2: Start the controller in the drying device to control the resistance wire 31 to be energized. After the resistance wire 31 is energized, the temperature rises, and the resistance wire 31 transfers heat to the disc 3; by heating the resistance wire 31 in advance, the resistance wire 31 is avo...

Embodiment approach

[0041] As an embodiment of the present invention, the other edge of the swash plate 21 is hinged to the buffer plate 25; the end face of the buffer plate 25 is in a static state and the angle between the upper end face of the disc 3 is 0-45 degrees, One of the edges of the buffer plate 25 is in contact with the inner wall of the ring cylinder 2, and the material of the buffer plate 25 is consistent with that of the inclined plate 21; After making the chicken feed fall from the other edge of the slant plate 21, the situation that the chicken feed is broken; The end face rolls and then falls on the upper end of the disc 3, which protects the chicken feed from being damaged. Part of the chicken feed will enter the angle between the slant plate 21 and the disc 3, and the chicken feed at the angle between the slant plate 21 and the disc 3 The feed will push the buffer plate 25, so that the buffer plate 25 will rotate around the other edge of the swash plate 21, so that the buffer p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap