Method for brazing dissimilar materials through assistance of carbon nano tube sponge middle layer

A technology of carbon nanotube sponge and dissimilar materials, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve problems such as low strength, achieve the effects of enhancing the performance of brazing joints, inhibiting formation and agglomeration, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

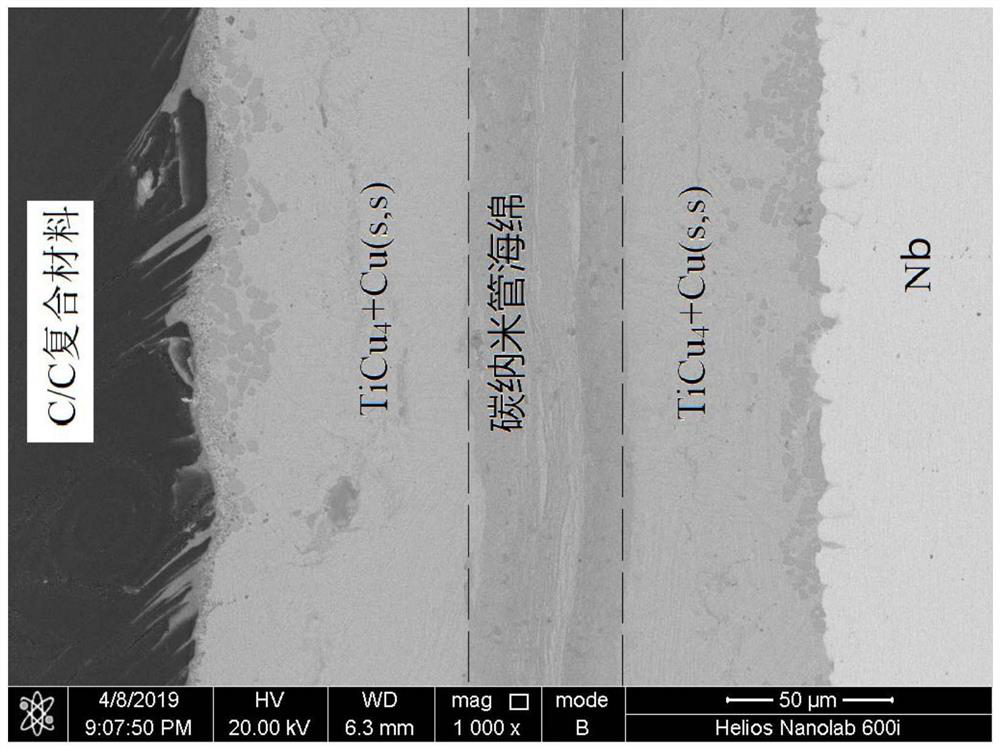

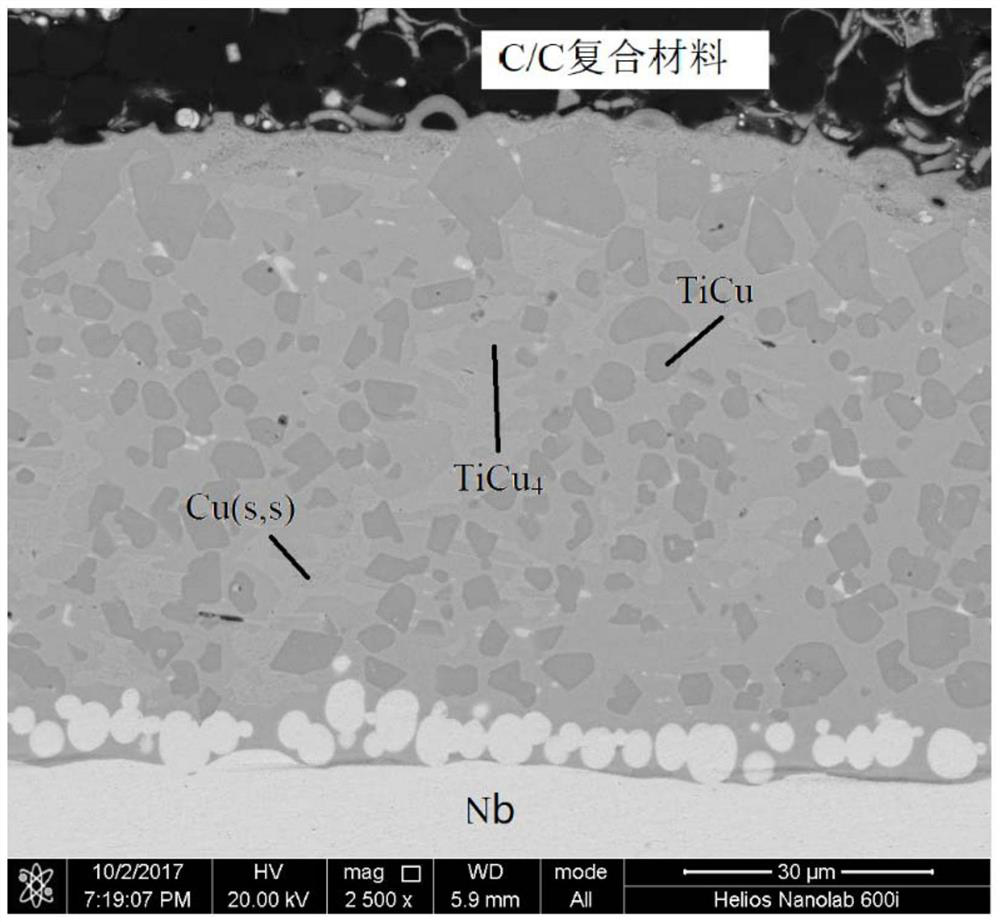

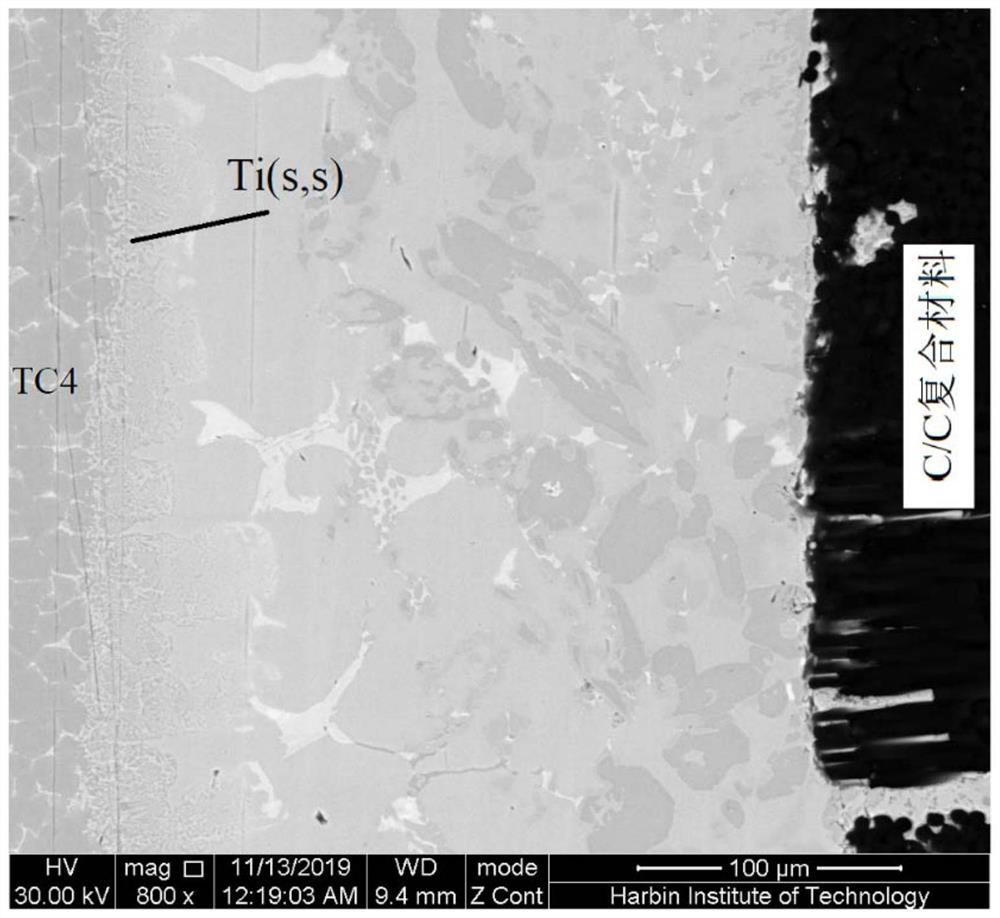

[0027] Specific Embodiment 1: In this embodiment, the method for assisting the brazing of dissimilar materials by the carbon nanotube sponge intermediate layer is carried out according to the following steps:

[0028] Step 1, mixing the carbon nanotube powder with a strong acid solution, and then performing ultrasonic cleaning at a constant temperature of 60°C to obtain a suspension;

[0029] Step 2, disperse the suspension obtained in step 1 into deionized water to obtain a mixed solution, then vacuum filter the mixed solution to obtain a filter cake, then continue to wash the filter cake, and finally peel off the filter cake and filter membrane;

[0030] Step 3, ultrasonically dispersing the obtained filter cake in step 2 into absolute ethanol, centrifuging, and retaining the supernatant;

[0031] Step 4, vacuum filter the supernatant obtained in step 3, peel off to obtain a filter cake, and finally dry to obtain a carbon nanotube sponge;

[0032] Step 5, setting brazing fi...

specific Embodiment approach 2

[0042] Embodiment 2: This embodiment differs from Embodiment 1 in that: the carbon nanotube powder in Step 1 is single-wall carbon nanotubes, double-wall carbon nanotubes or multi-wall carbon nanotubes.

specific Embodiment approach 3

[0043]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the ratio of the mass of the carbon nanotube powder described in step one to the volume of the strong acid solution is (10-200) mg: (10-30) mL .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com