Process for refining primary brine and coproducing slow-release compound fertilizer

A compound fertilizer and brine refining technology, applied in inorganic fertilizers, calcareous fertilizers, fertilizer mixtures, etc., can solve the problems of single fertilizer element, uneven distribution of salt mud components, poor fertilizer efficiency and release performance, etc. The effect of low content, improving the quality of primary brine, and avoiding excessive fertilizer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

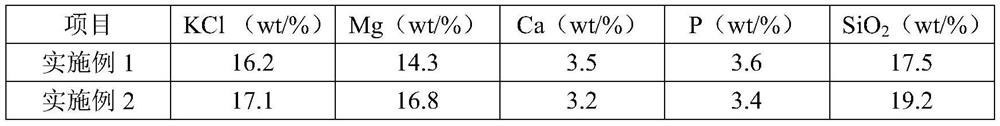

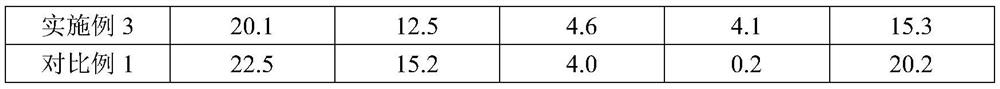

Examples

Embodiment 1

[0029] (1) Heat the dechlorinated brine solution in the water distribution tank to 60°C, pour it into the chemical salt tank, mix and dissolve it with solid industrial grade potassium chloride raw material, and prepare 300g / L coarse brine.

[0030] (2) The crude brine flows into the crude brine storage tank through the baffle tank, and 30% KOH solution is added into the baffle tank to adjust the pH value to 10.

[0031] (3) the solution with a pH value of 10 in step (2) is squeezed into 300m 3 In the clarifier tank, the flow rate is 30m 3 / s, add 5% H 3 PO 4 solution, adjust the pH value to 9, and generate a solid-liquid mixture.

[0032] (4) Naturally cool and settle the solid-liquid mixture in the clarification tank, the temperature drops to 20 degrees, and the residence time of the solid-liquid mixture in the clarification tank is controlled at 10s.

[0033] (5) The supernatant in the clarification tank is filtered through a Gore filter, and the filtrate is sent to the ...

Embodiment 2

[0037] (1) Heat the dechlorinated brine solution in the water distribution tank to 60°C, pour it into the chemical salt tank, mix and dissolve it with solid industrial grade potassium chloride raw material, and prepare 300g / L coarse brine.

[0038] (2) The crude brine flows into the crude brine storage tank through the baffle tank, and 30% KOH solution is added into the baffle tank to adjust the pH value to 10.

[0039] (3) the solution with a pH value of 10 in step (2) is squeezed into 300m 3 In the clarifier tank, the flow rate is 30m 3 / s, add 5% H 3 PO 4 solution, adjust the pH value to 9, and generate a solid-liquid mixture.

[0040] (4) Naturally cool and settle the solid-liquid mixture in the clarification tank, the temperature drops to 40 degrees, and the residence time of the solid-liquid mixture in the clarification tank is controlled at 10s.

[0041] (5) The supernatant in the clarification tank is filtered through a Gore filter, and the filtrate is sent to the ...

Embodiment 3

[0045] (1) Heat the dechlorinated brine solution in the water distribution tank to 80°C, pour it into the chemical salt tank, mix and dissolve it with solid industrial grade potassium chloride raw material, and prepare 330g / L crude brine.

[0046] (2) The crude brine flows into the crude brine storage tank through the baffle tank, and 48% KOH solution is added into the baffle tank to adjust the pH value to 10.

[0047] (3) the solution with a pH value of 10 in step (2) is squeezed into 300m 3 In the clarifier tank, the flow rate is 30m 3 / s, add 20% H 3 PO 4 solution, adjust the pH value to 9, and generate a solid-liquid mixture.

[0048] (4) Naturally cool and settle the solid-liquid mixture in the clarification tank, the temperature drops to 40 degrees, and the residence time of the solid-liquid mixture in the clarification tank is controlled at 25s.

[0049] (5) The supernatant in the clarification tank is filtered through a Gore filter, and the filtrate is sent to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com