A thermal power plant desulfurization wastewater zero-discharge treatment system and method thereof

A desulfurization wastewater and treatment system technology, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of reduced resource recovery rate, reduced salt content, environmental pollution, etc., to increase Treatment effect, increased crystallization effect, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

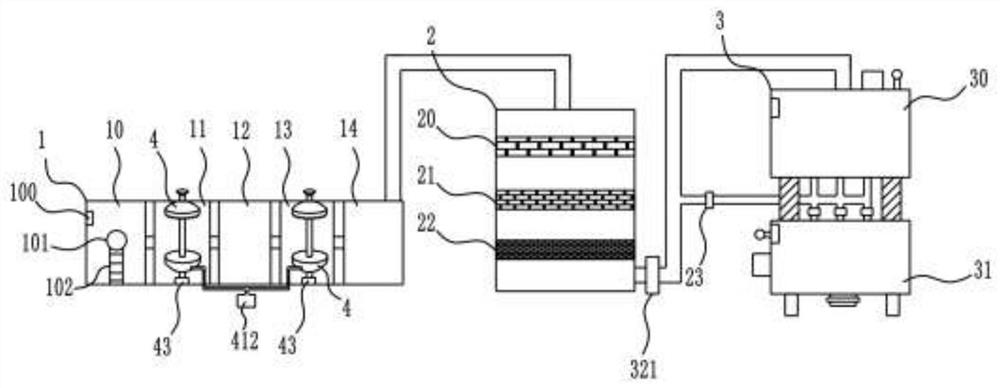

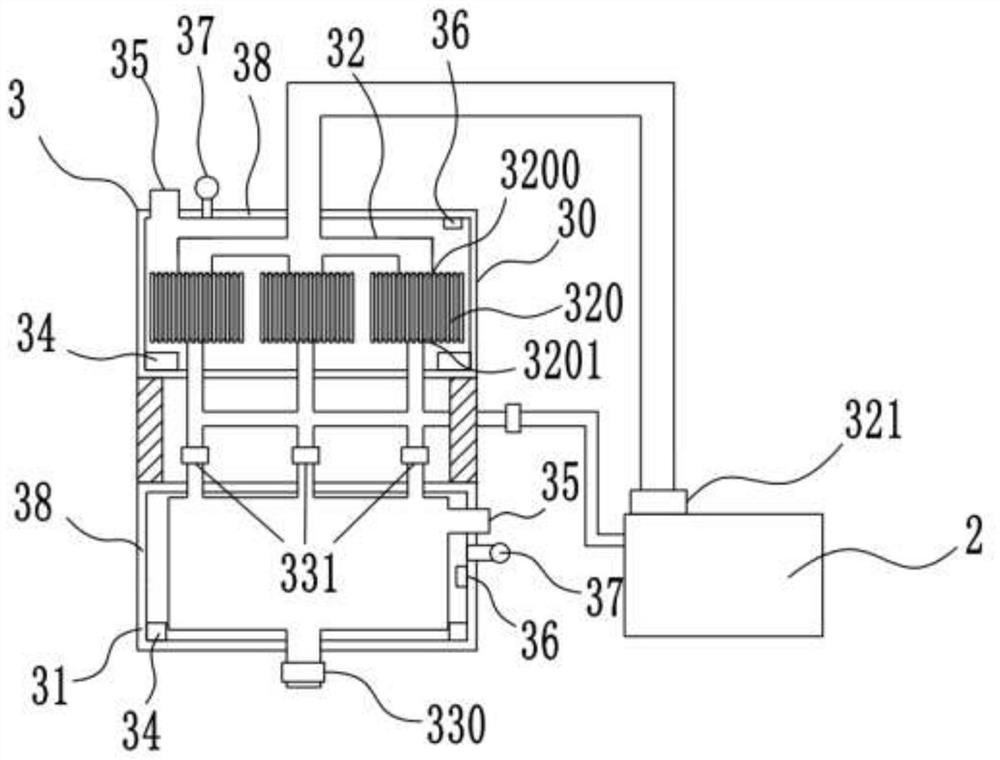

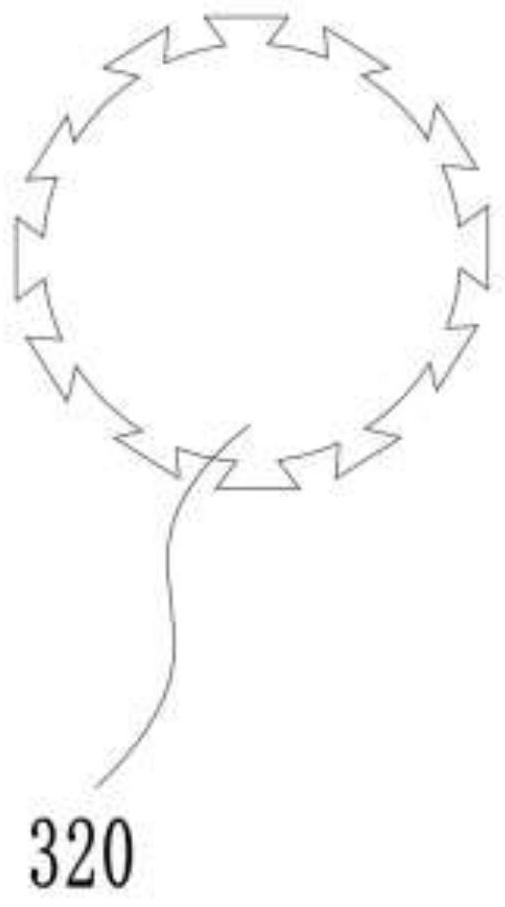

[0036] Example: such as figure 1 A thermal power plant desulfurization wastewater treatment system with zero discharge mainly includes a wastewater pretreatment system 1, a membrane concentration system 2, an evaporation crystallization device 3, a reagent addition device 4, a controller 5, and a power supply device;

[0037] The wastewater pretreatment system 1 includes a wastewater buffer tank 10, a primary coagulation sedimentation tank 11, a primary clarification tank 12, a secondary coagulation sedimentation tank 13, and a secondary clarification tank 14 connected sequentially through connecting pipes. A liquid level sensor 100 is provided, and an inspection hole 101 and an inspection escalator 102 are provided on the waste water buffer pool 10. The liquid level change in the waste water buffer pool 10 is understood through the liquid level sensor 100, and the waste water treatment rate is adjusted according to the liquid level change. The hole 101 and the maintenance esc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com