Production of high purity lithium carbonate from brines

A lithium carbonate, brine technology, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of waste of resources, technical complexity, high cost, etc., to achieve improved productivity, low technical complexity, and shortened time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0168] A) Removal of calcium ions, magnesium ions and strontium ions by precipitation

[0169] To 1 l of brine (37 g / l of Ca 2+ , 3.7g / l of Mg 2+ , 2.3g / l of Sr 2+ , 65g / l Na + and 140ppm Li + (0.014g / l)) adding 0.32l of Na 2 CO 3solution (400g / l, 129.3g) and 0.05l of NaOH (1000g / l, 48.8g). The brine and precipitating agent are mixed here at a stirring rate of 350 rpm. The dispersion formed was filtered off via a filter funnel at a pressure of 2 bar. Purified brine contains Ca at a concentration below 20ppm 2+ 、Sr 2+ and Mg 2+ and 140ppm Li + And has a pH of 11.

[0170] B) Removal of Ca by chelating resins containing aminomethylphosphonic acid groups 2+ 、Sr 2+ and Mg 2+

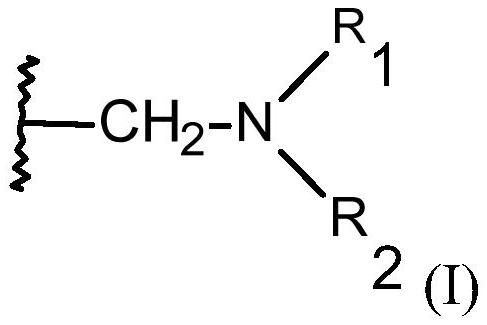

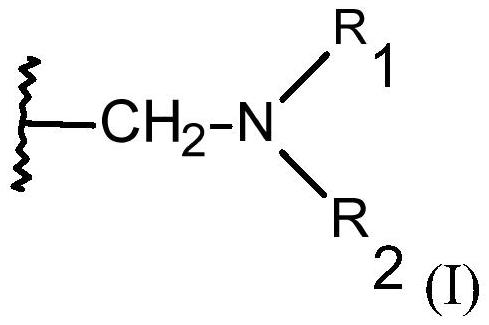

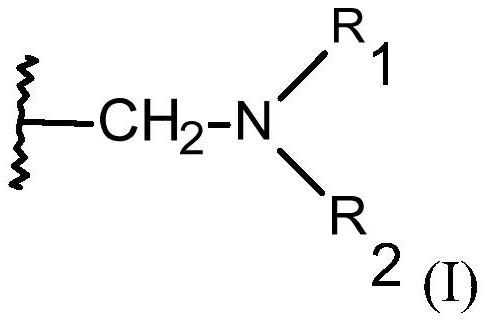

[0171] The macroporous monodisperse chelating resin that contains the functional group with structural element (I) that vector cylinder fills 50ml, wherein R 1 and R 2 independently of each other = -CH 2 PO(OX 1 ) 2 、-CH 2 PO(OH)OX 2 or hydrogen, where both cannot be hydrogen at ...

example 2

[0178] A) Removal of calcium ions, magnesium ions and strontium ions by precipitation

[0179] To 1 l of brine (37 g / l of Ca 2+ , 3.7g / l of Mg 2+ , 2.3g / l of Sr 2+ , 65g / l Na + and 140ppm Li + (0.014g / l)) add 0.32ml of Na 2 CO 3 solution (400g / l, 129.3g) and 0.05l of NaOH (1000g / l, 48.8g). The brine and precipitating agent are mixed here at a stirring rate of 350 rpm. The dispersion formed was filtered off via a filter funnel at a pressure of 2 bar. Purified brine contains Ca at a concentration below 20ppm 2+ 、Sr 2+ and Mg 2+ and 140ppm Li + And has a pH of 11.

[0180] B) Removal of Ca by chelating resins containing iminodiacetic acid groups 2+ 、Sr 2+ and Mg 2+

[0181] The macroporous monodisperse chelating resin that contains the functional group with structural element (I) that vector cylinder fills 50ml, wherein R 1 and R 2 independently of each other = -CH 2 COOX or hydrogen, but R 1 and R 2 cannot both be hydrogen at the same time, and X is hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com