Calcium europium nitride solid solution powder and preparation method thereof

A technology of nitride and solid solution, which is applied in the chemical industry, can solve problems such as failure to meet production requirements, long time consumption, and difficult reaction, and achieve high product uniformity and consistency, avoid uncontrollable impurities, and strict process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

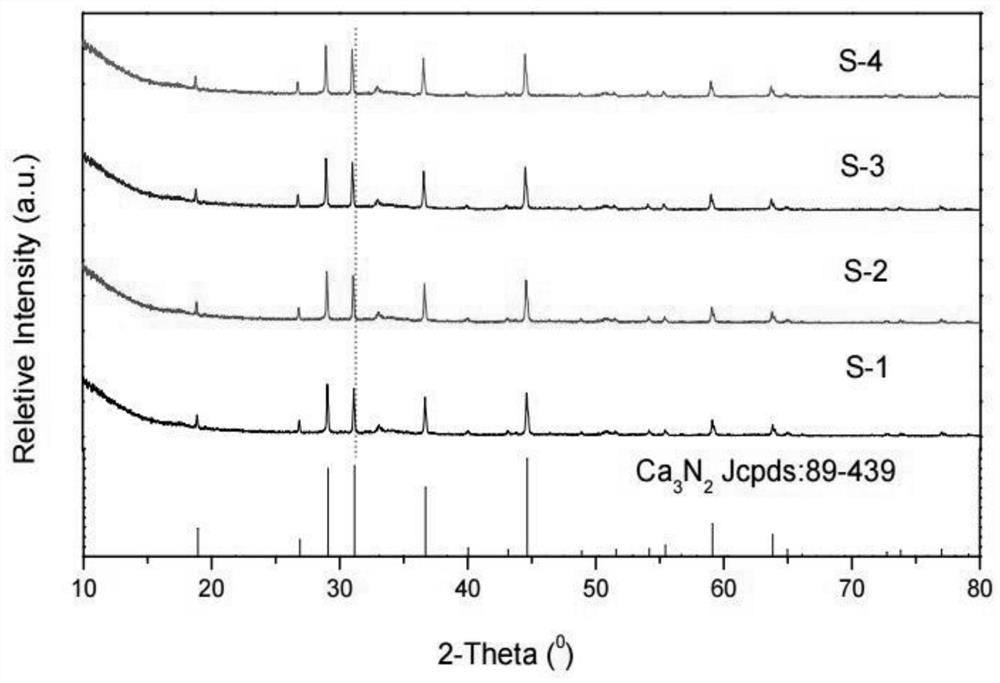

[0036] Embodiment 1: Preparation (Ca 0.995 Eu 0.005 ) 3 N 2 ;

[0037] Weigh 981.3g of calcium metal and 1.87g of europium metal, wash the furnace with argon three times in a vacuum melting furnace, flush with argon to 80KPa, heat to 780°C to melt into a slurry state, cast and cool to obtain an alloy ingot. After cleaning the surface of the alloy ingot, put it into a hydrogen breaker furnace, heat it to 220°C for activation after vacuuming three times, pass in hydrogen, and then heat it to 360°C for 4 hours, then heat it to 580°C and vacuumize to remove the hydrogen. After it is less than 40pa (displayed by the instrument), cool down to below 300°C, start to feed nitrogen to 0.5MPa, then gradually increase the temperature to 460°C, maintain the gas pressure at 0.5MPa, keep it for 3 hours, then raise the temperature to 610°C for 5 hours, Within 5 minutes, the pressure gauge shows that it is no longer declining, and the reaction is over. Then cool to room temperature, put t...

Embodiment 2

[0038] Embodiment 2: Preparation (Ca 0.985Eu 0.015 ) 3 N 2 ;

[0039] Weigh 945.3g of calcium metal and 54.7g of europium metal, wash the furnace with argon three times in a vacuum melting furnace, flush with argon to 80KPa, heat to 800°C to melt into a slurry state, pour and cool to obtain an alloy ingot. After cleaning the surface of the alloy ingot, put it into a hydrogen breaker furnace, heat it to 220°C for activation after vacuuming three times, pass in hydrogen, and then heat it to 360°C for 4 hours, then heat it to 580°C to remove the hydrogen, and the vacuum degree is less than After 40pa (instrument display), cool down to below 300°C, start feeding nitrogen gas to 0.55MPa, then gradually raise the temperature to 460°C, maintain the gas pressure at 0.5MPa, keep it for 4 hours, then raise the temperature to 610°C for 5 hours, 5min The internal pressure gauge shows that it is no longer declining, and the reaction ends. Then cool to room temperature, fill the materi...

Embodiment 3

[0040] Embodiment 3: preparation (Ca 0.98 Eu 0.02 ) 3 N 2 ;

[0041] Weigh 728g of calcium metal and 72g of europium metal, wash the furnace with argon three times in a vacuum melting furnace, flush with argon to 80KPa, heat to 810°C, melt into a slurry state, pour and cool to obtain an alloy ingot. After cleaning the surface of the alloy ingot, put it into a hydrogen breaker furnace, heat it to 220°C for activation after vacuuming three times, pass in hydrogen, and then heat it to 360°C for 4 hours, then heat it to 580°C to remove the hydrogen, and the vacuum degree is less than After 40pa (instrument display), cool down to below 300°C, start feeding nitrogen gas to 0.6MPa, then gradually raise the temperature to 460°C, maintain the gas pressure at 0.6MPa, keep it for 4 hours, then raise the temperature to 610°C for 5 hours, 5min The internal pressure gauge shows that it is no longer declining, and the reaction ends. Then cool to room temperature, fill the material with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com