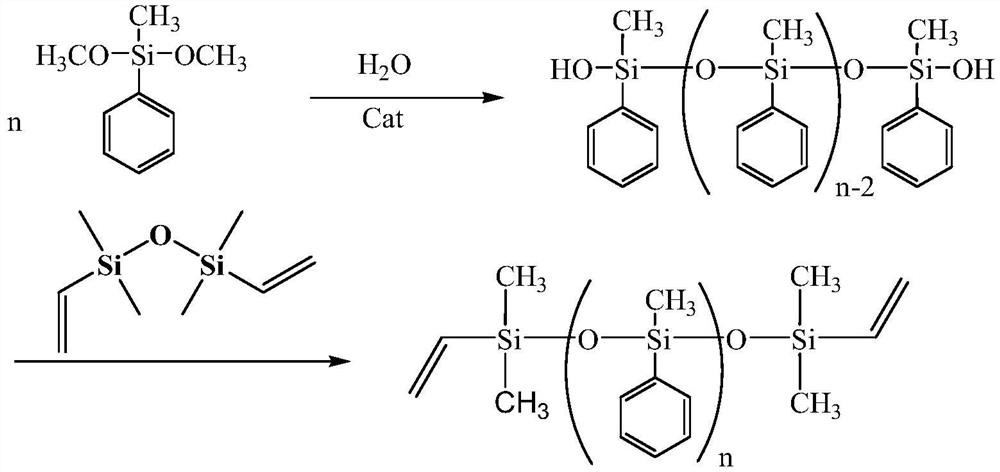

Preparation method of vinyl-terminated methyl phenyl polysiloxane

A technology of terminal methyl phenyl and vinyl sealing, applied in the field of organosilicon synthesis, can solve problems such as unreasonable use of catalysts, and achieve the effects of easy recovery and reuse, good loading effect, and satisfying industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 500g of methylphenyldimethoxysilane and 400g of deionized water into the reactor, stir, add 2.5g of halloysite nanotube-supported catalyst, heat to 70°C, react for 2h, and collect the distillate with a condenser , after the reaction is over, adjust the system pressure to -0.096Mpa, remove water and low boilers by distillation under reduced pressure, and obtain a colorless and transparent hydroxyl-terminated methylphenyl siloxane oligomer intermediate, and then add 30g of tetramethyl phenylsiloxane Divinyl disiloxane, nitrogen protection, control the reaction temperature at 80°C, stir the reaction for 3h, after the reaction is completed, filter, recover the rockite nanotube-supported catalyst, adjust the pressure of the system to -0.096Mpa, at 180°C Under reduced pressure, the low boilers were removed by distillation under reduced pressure to obtain a colorless oily liquid vinyl-terminated methylphenylpolysiloxane. The yield is 83.6%, and the refractive index (20°C) ...

Embodiment 2

[0031] Add 500g of methylphenyldimethoxysilane and 500g of deionized water into the reactor, add 5g of halloysite nanotube-supported catalyst under stirring, heat to 80°C, react for 2h, and collect the distillate with a condenser , after the reaction is over, adjust the system pressure to -0.096Mpa, remove water and low boilers by distillation under reduced pressure, and obtain a colorless and transparent hydroxyl-terminated methylphenyl siloxane oligomer intermediate, and then add 25g tetramethyl phenylsiloxane Divinyl disiloxane, nitrogen protection, control the reaction temperature at 85°C, stir the reaction for 5h, after the reaction, filter, recover the rockite nanotube-supported catalyst, adjust the system pressure to -0.096Mpa, at 200°C Under reduced pressure, the low boilers were removed by distillation under reduced pressure to obtain a colorless oily liquid vinyl-terminated methylphenylpolysiloxane. The yield is 87.6%, and the refractive index (20°C) is 1.551.

[00...

Embodiment 3

[0037] Add 500g of methylphenyldimethoxysilane and 450g of deionized water into the reactor, add 4g of halloysite nanotube-supported catalyst under stirring, heat to 70-80°C, react for 2h, collect the distillate with a condenser After the reaction is finished, adjust the system pressure to -0.096Mpa, remove water and low boilers by distillation under reduced pressure, and obtain a colorless and transparent hydroxyl-terminated methylphenyl siloxane oligomer intermediate, and then add 40g Tetramethyldivinyldisiloxane, under the protection of nitrogen gas, under the condition of reaction temperature of 82 ℃, stirred and reacted for 4h, after the reaction was completed, filtered and recovered the catalyst supported by calcite nanotubes, adjusted the system pressure to -0.096Mpa, At 190°C, the low boilers were removed by distillation under reduced pressure to obtain a colorless oily liquid vinyl-terminated methylphenylpolysiloxane with a yield of 85.9% and a refractive index (20°C) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com