A solvent-free weather-resistant epoxy anti-corrosion coating and preparation method thereof

An epoxy anti-corrosion coating and weather-resistant technology, applied in the field of coatings, can solve the problems of easy powdering, easy degradation and chain scission, poor weather resistance of the coating film, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

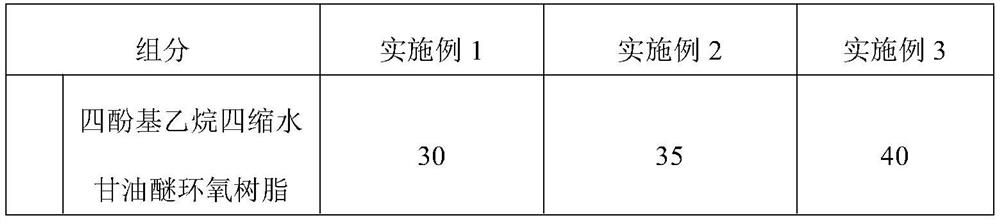

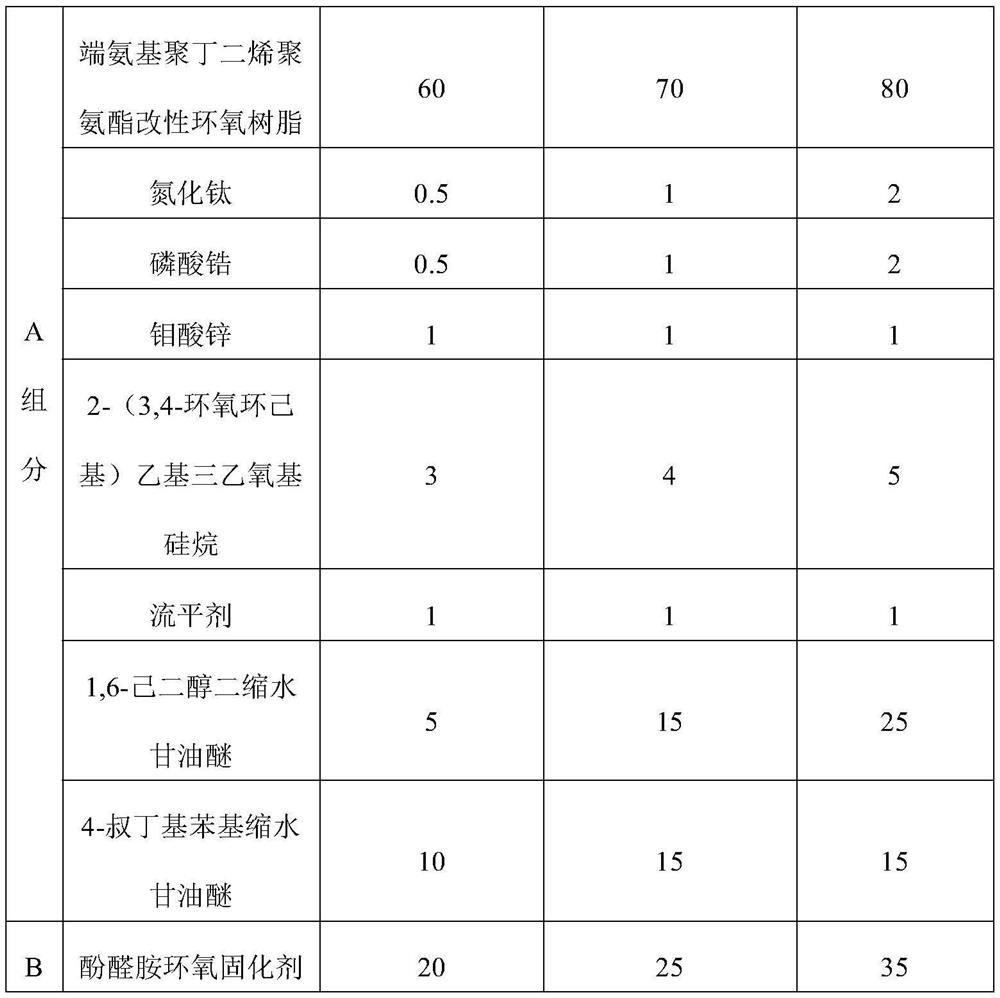

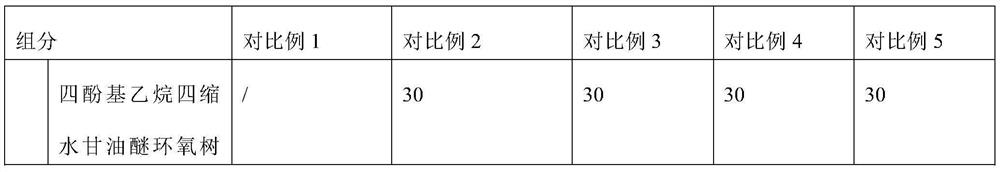

[0021] The following table is the formula table (unit: part) of 3 embodiments of solvent-free weather-resistant epoxy anticorrosion coating of the present invention:

[0022]

[0023]

[0024] A preparation method of the solvent-free weather-resistant epoxy anticorrosion coating comprises the following steps:

[0025] a. Mix tetraphenol ethane tetraglycidyl ether epoxy resin with additives, disperse at 600-800r / min for 15-30min;

[0026] b. Mix terminal reaction group polybutadiene polyurethane modified epoxy resin, silane coupling agent and nano inorganic filler, disperse at 800-1000r / min for 15-30min;

[0027] c. Mix the material obtained in step a with the material obtained in step b, stir evenly, and then grind to a fineness of less than 50 μm to obtain component A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com