Production method of flax knitted garment fabric

A production method and linen technology, applied in knitting, weft knitting, and elongation of fabrics, can solve the problems of poor wearing performance, easy wrinkling, poor appearance and elasticity of linen knitted fabrics, etc., and achieve structural relaxation, The effect of tight tissue structure and plump appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

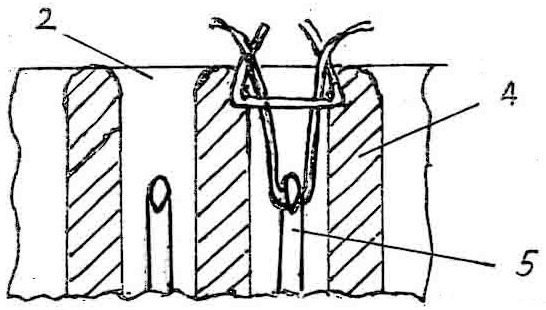

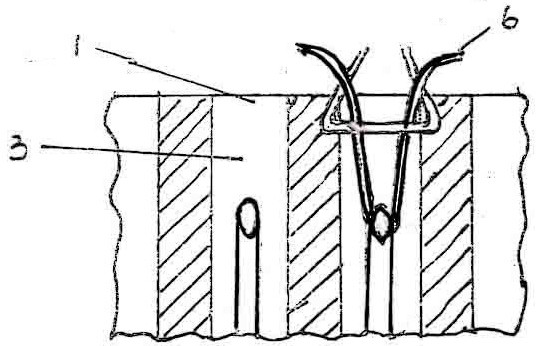

[0081]Production process of linen / stretch polyester fiber (PTT) double-sided pique mesh dyed cloth

[0082]The veil of the fabric is pure linen knitting yarn, which has super moisture absorption and breathability, is dry and comfortable, and has a variety of health care functions. The bottom yarn of the fabric is elastic polyester fiber (PTT), which has good elasticity, soft and comfortable touch, and good dyeing performance. The outer layer of flax and the inner layer of PTT fibers are connected to each other, which improves the elasticity of the fabric and solves the shortcomings of linen knitted fabrics that are easy to wrinkle and difficult to handle. The one-way wet tissue structure has the effect of moisture wicking, quick-drying and non-ironing.

[0083]The specific production process is:

[0084]Linen knitting yarn → after soft waxing treatment, knitting and weaving with elastic polyester fiber (PTT) → grey fabric inspection → grey fabric repair → grey fabric pre-sizing → singeing → ...

Embodiment 2

[0086]Production process of linen / long-staple cotton yarn double-sided dyed jersey

[0087]The veil of the fabric is pure linen knitting yarn, which has super moisture absorption and breathability, is dry and comfortable, and comes with a variety of health care functions. The bottom yarn of the fabric is long-staple cotton yarn, which is soft and comfortable, and has good wearing performance. Good elasticity improves the wrinkle resistance of linen knitted fabrics.

[0088]Linen knitting yarn → after soft waxing treatment, knitting and weaving with long-staple cotton knitting yarn → grey fabric inspection → grey fabric repairing → singeing → mercerizing → oxygen bleaching pretreatment → biological enzyme polishing → dyeing → softening → scouring, rolling water , Drying→Liquid ammonia finishing→Padding finishing liquid, tentering, setting→preshrinking→inspection→coiling.

Embodiment 3

[0090]Production process of linen / polyester low stretch yarn double-sided dyed jersey

[0091]The veil of the fabric is pure linen knitting yarn, with super moisture absorption and breathability, dry and comfortable, with multiple functions. The bottom yarn of the fabric is polyester low-stretch yarn, which has good elasticity, good stiffness, low cost, good dyeing fastness, and can improve the wrinkle resistance of the fabric. The outer layer of flax and inner layer of polyester fibers form a unidirectional moisture-conducting structure, which has the effect of moisture wicking, quick-drying and non-ironing.

[0092]Linen knitting yarn → after soft waxing treatment, knitting and weaving with polyester low-stretch yarns, knitting weaving → grey fabric inspection → grey fabric repair → grey fabric pre-sizing → singeing → mercerizing → oxygen bleaching pretreatment → biological enzyme polishing → disperse dye dyeing polyester fiber → Reactive dyes dye linen → softening → scouring, rolling, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com