Preparation method and application of composite non-woven fabric

A non-woven fabric and silk fiber technology, which is applied in the field of composite non-woven fabric preparation, can solve the problems of flying flowers, easy side leakage, and influence on the uniformity of the fiber web, and achieve enhanced safety and absorbency, and easy menstrual bleeding. Penetrating and solving the effect of side leakage of menstrual blood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

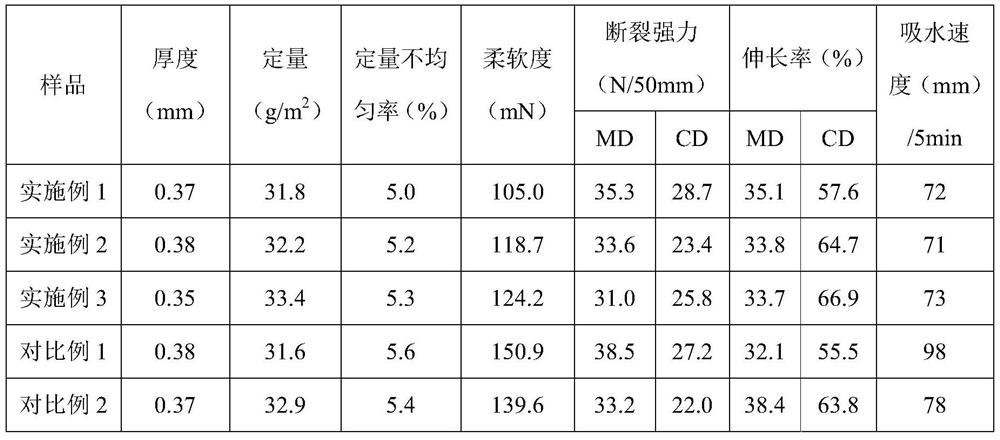

Embodiment 1

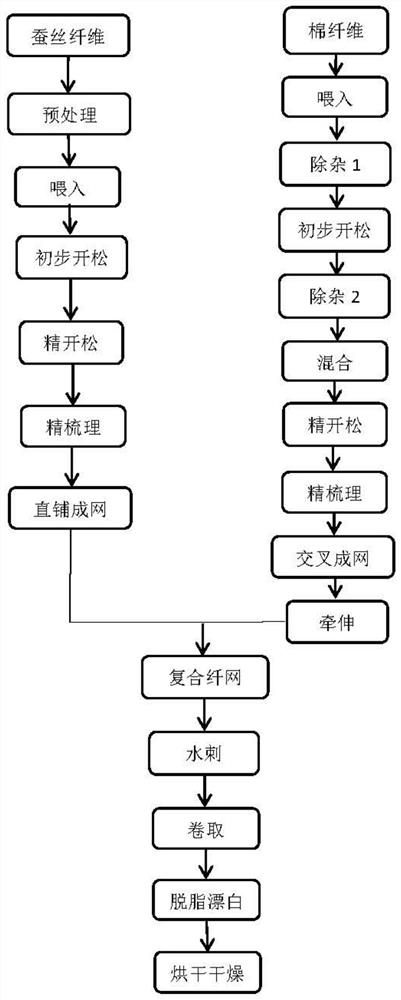

[0073] Embodiment 1 A kind of preparation method of composite nonwoven fabric

[0074] (1) Silk fiber pretreatment

[0075] Under the conditions of ambient temperature 25°C and humidity 55%, spray oil on the silk fiber. The main component of the oil is antistatic agent (model: S10), and it is used after mixing according to the ratio of antistatic agent: water = 1:6 , according to the ratio of oil agent: silk fiber = 1:30, evenly spray on the fiber, and treat for 36 hours.

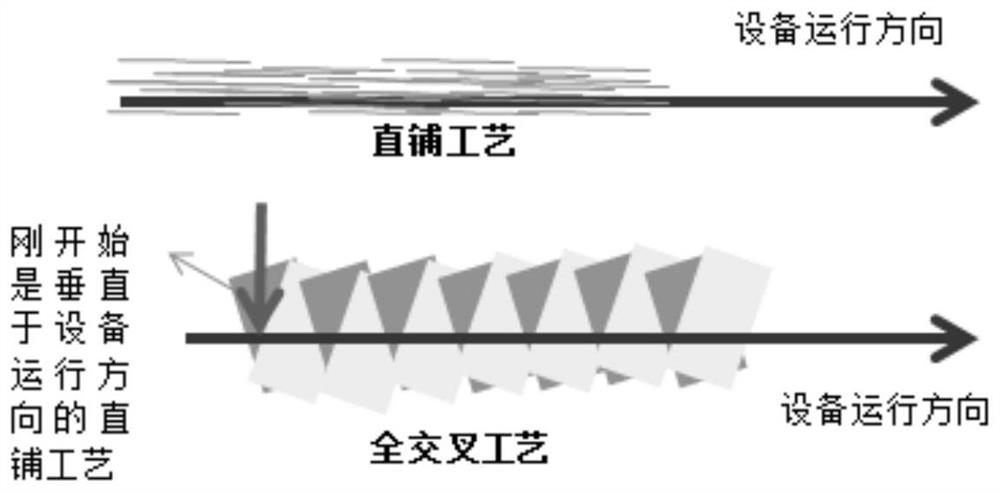

[0076] (2) Preparation of silk fiber web

[0077] The pretreated 100% silk natural fiber is used to grab and feed the silk fiber by the disc plucking machine, and the silk fiber is initially opened, and then transported to the FA106 opener by air flow for fine opening, so that the silk is further decomposed. The silk enters the ZWF1206 type pre-carding machine for combing to make the silk single fiber. After being collected and stored in the ZGB1026 type cotton storage box, the pressure in the cotton stor...

Embodiment 2

[0091] Embodiment 2 A kind of preparation method of composite nonwoven fabric

[0092] (1) Silk fiber pretreatment

[0093] Under the conditions of ambient temperature 22°C and humidity 52%, spray oil on silk fibers. The main component of oil is antistatic agent (model: S10), and it is used after mixing according to the ratio of antistatic agent: water = 1:3 , according to the ratio of oil agent: silk fiber = 1:20, evenly spray on the fiber, and treat for 24 hours.

[0094] (2) Preparation of silk fiber web

[0095] The pretreated 100% silk natural fiber is used to grab and feed the silk fiber by the disc plucking machine, and the silk fiber is initially opened, and then transported to the FA106 opener by air flow for fine opening, so that the silk is further decomposed. The silk enters the ZWF1206 type pre-carding machine for combing to make the silk single fiber. After being collected and stored in the ZGB1026 type cotton storage box, the pressure in the cotton storage box...

Embodiment 3

[0110] Embodiment 3 A kind of preparation method of composite non-woven fabric

[0111] (1) Silk fiber pretreatment

[0112] Under the condition of ambient temperature of 28°C and humidity of 60%, spray oil agent on silk fiber. The main component of oil agent is antistatic agent (model: S10), and it is used after mixing according to the ratio of antistatic agent: water = 1:10 According to the ratio of oil agent: silk fiber = 1:100, it is evenly sprayed on the fiber and treated for 48 hours.

[0113] (2) Preparation of silk fiber web

[0114] The pretreated 100% silk natural fiber is used to grab and feed the silk fiber by the disc plucking machine, and the silk fiber is initially opened, and then transported to the FA106 opener by air flow for fine opening, so that the silk is further decomposed. The silk enters the ZWF1206 pre-carding machine for fine combing to make the silk single fiber. After being collected and stored in the ZGB1026 cotton storage box, the pressure in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com