A kind of lithium battery and preparation method thereof

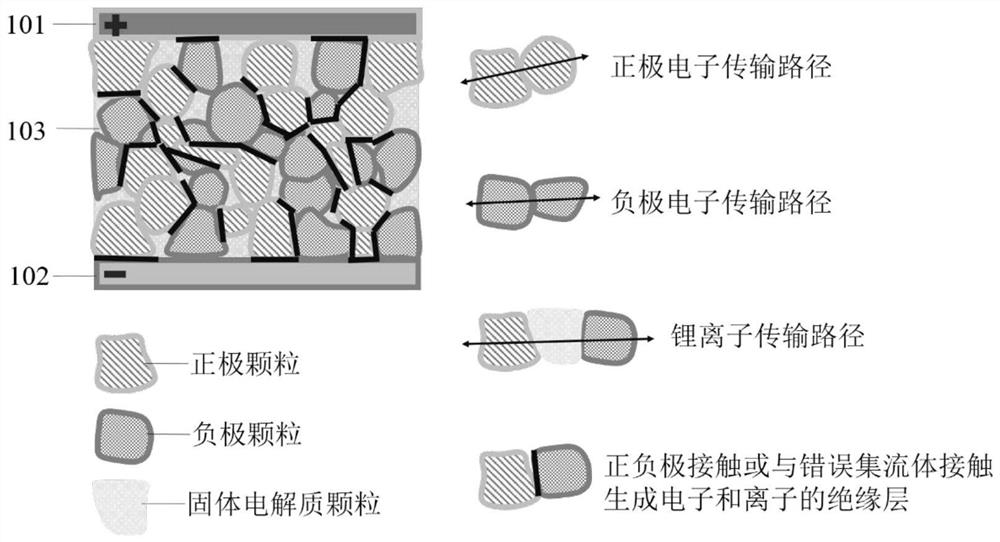

A lithium battery and lithium ion technology, which is applied in the manufacture of electrolyte batteries, electrode manufacture, battery electrodes, etc., can solve problems such as difficulties, increase in battery internal resistance, powdering and peeling of positive and negative electrode layers, and simplify the preparation process and process , Reduce the preparation process and process, the effect of small volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] On the other hand, the present invention provides the preparation method of above-mentioned lithium battery, it is characterized in that, comprises the following steps:

[0046] (1) Prepare active functional layer slurry mixed with positive electrode active material, negative electrode active material and material conducting lithium ions;

[0047] (2) The active functional layer slurry prepared in step (1) is filled between the positive electrode current collector and the negative electrode current collector to obtain a lithium battery.

[0048]This preparation method avoids the process steps in the prior art that need to separately prepare the positive electrode coating slurry and the negative electrode coating slurry, thereby greatly simplifying the battery preparation process and process, and the lithium battery prepared by this method has the advantages of positive, negative Outside the negative current collector, there is only one layer of structure, and the deinte...

Embodiment 1

[0060] (1) Preparation of a positive electrode active material with a coating layer

[0061] 1000g LiCoO 2 (particle size about 5μm), 20g LiH 2 PO 4 and 1000 mL of solvent water were mixed evenly and kept stirring, and the spray dryer was used to carry out the spray drying operation under the air pressure condition of 25 NL / min and the temperature condition of 220 ℃, and the obtained product powder was taken out and placed in a muffle furnace and heated to 250 ℃, keep for 5h, LiH can be produced 2 PO 4 Coated LiCoO 2 Positive active material. Microscopically, the coating is uniform, and the coating thickness is about 30 nm.

[0062] (2) Preparation of negative electrode active material with coating layer

[0063] Under an inert gas atmosphere, put 1000g of negative electrode active material artificial graphite and 100g of lithium metal powder into a ball mill jar, add 1500mL of toluene as a solvent, and ball mill at a speed of 150 rpm for 20h, take out the obtained prod...

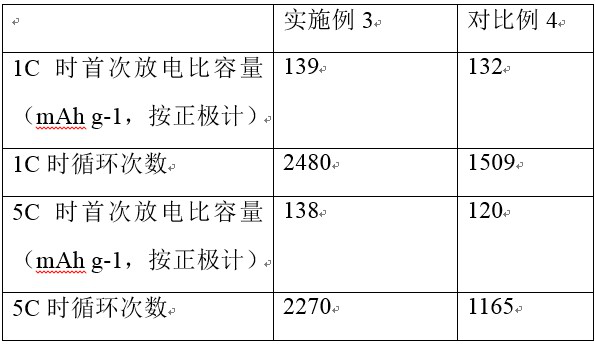

Embodiment 2

[0069] The same steps as in Example 1 were used to prepare the lithium battery of this example, the difference being that:

[0070] The positive active material used is LiH 2 PO 4 The coating mass ratio is 55%:45% NCM811:LiCoO 2 material, the negative electrode active material used is lithium metal-coated carbon-containing shell Li 4 Ti 5 o 12 Material. Step (3) In the preparation of active functional layer coating F, the amount of positive electrode active material is 1000 g, Li 7 La 3 Zr 2 o 12 The amount of solid electrolyte was 150 g, and the amount of negative active material was 1200 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com