A kind of preparation method of low lithium manganese ratio layered lithium manganese oxide cathode material

A technology of layered lithium manganate and positive electrode materials, which is applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of low utilization rate of raw materials, irregular shape, and uneven particle size, so as to improve utilization rate, Excellent crystallinity and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

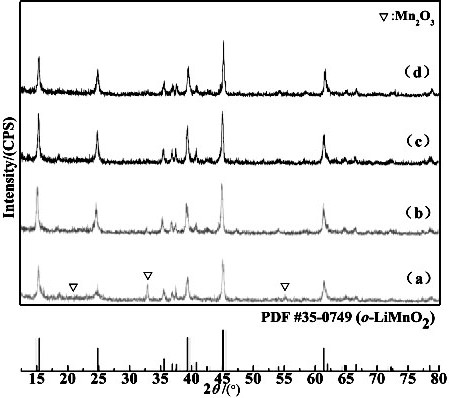

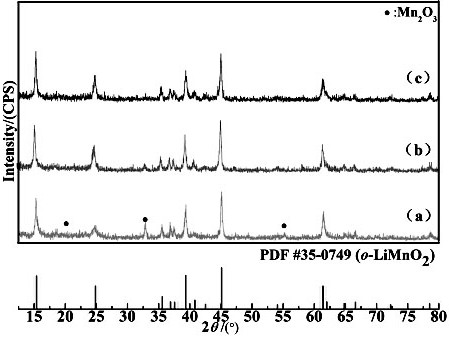

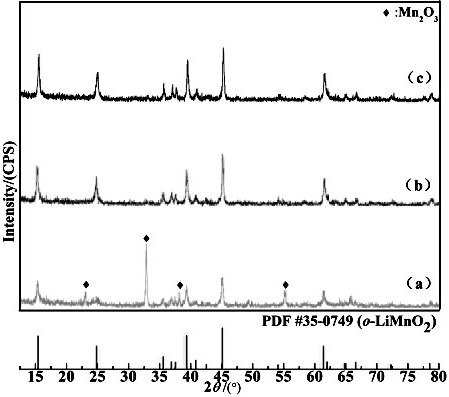

Embodiment 1

[0039] This embodiment provides a method for preparing a low lithium manganese ratio layered lithium manganate positive electrode material, comprising the following steps:

[0040] (a) Lithium hydroxide and manganese trioxide are mixed according to the lithium-manganese molar ratio of 1.5:1, the ball-to-material ratio is 6:1, and the speed is 120 rpm;

[0041] (b) Mix the mixture with potassium hydroxide, add the solution for magnetic stirring to form a mixed solution, the pH of the mixed solution is 13.15, and the magnetic stirring time is 2 hours;

[0042] (c) Place the mixed solution in a fully mixed tank reactor for a homogeneous reaction at 180°C for 10 hours, and the speed of the homogeneous reactor is 5 rpm;

[0043] (d) Wash the product obtained by the homogeneous reaction, put it in a vacuum drying oven with a vacuum degree of 0.08MPa and dry it, and finally obtain the target product o -LiMnO 2 .

Embodiment 2

[0045] This example provides a method for preparing layered lithium manganate as a positive electrode material for lithium batteries with a low lithium-manganese ratio. The preparation process is basically the same as that in Example 1. The pH of the mixture formed by stirring is different, pH=13.24.

Embodiment 3

[0047]This example provides a method for preparing layered lithium manganate as a positive electrode material for lithium batteries with a low lithium-manganese ratio. The preparation process is basically the same as that in Example 1. The pH of the mixture formed by stirring is different, pH=13.31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com