Method for reducing concentration of chloride ions in wastewater

A chlorine ion concentration, waste water technology, applied in chemical instruments and methods, gaseous discharge waste water treatment, water pollutants, etc., can solve problems such as high salt content, strong volatility, and affecting ecological environment balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

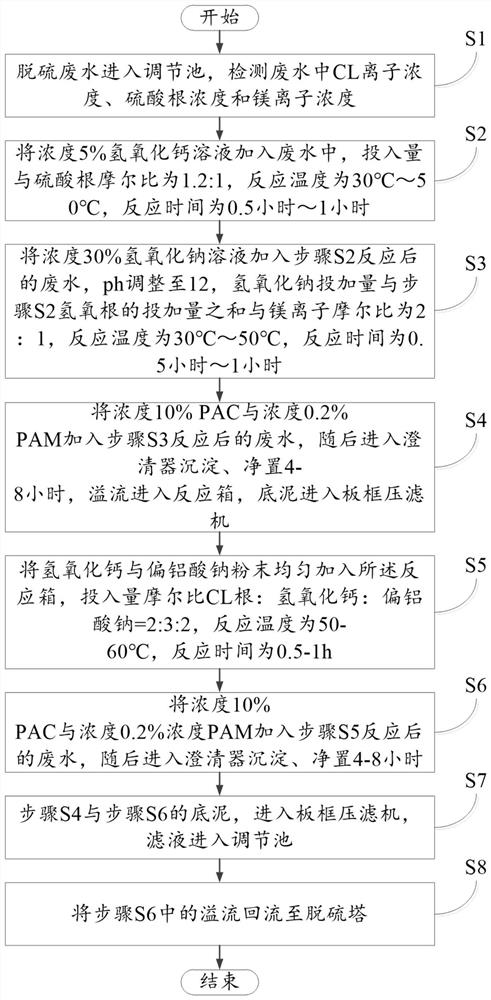

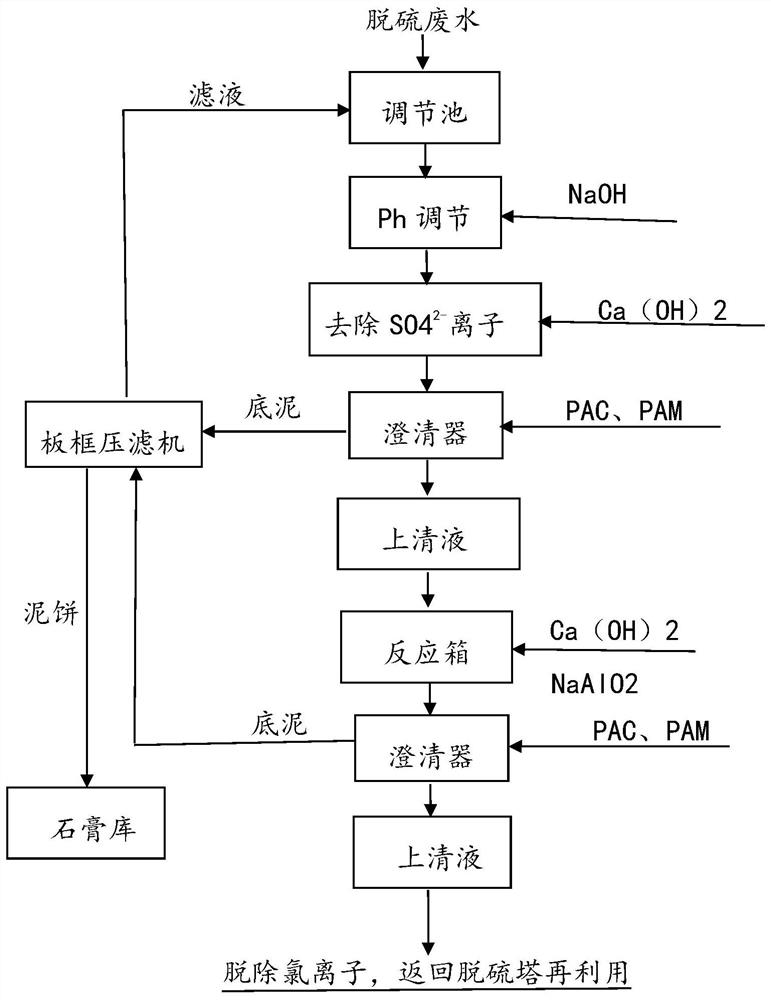

Method used

Image

Examples

specific Embodiment 1

[0046] 1000kg of desulfurization wastewater enters the regulating tank, and the ion concentration in the wastewater is detected, CL ions are 18000mg / L, magnesium ions are 7500mg / L, and sulfate ions are 6800mg / L.

[0047] Add 126kg of calcium hydroxide solution of 5% concentration in reaction tank, reaction generates calcium sulfate precipitation, removes the sulfate radical ion in waste water. Hydroxide in calcium hydroxide solution combines with magnesium ions to form magnesium hydroxide precipitate.

[0048] Add 66 kg of 30% concentration of sodium hydroxide solution in the regulating tank, adjust the pH of the waste water to 12, and eliminate all magnesium ions.

[0049] Add 0.2kg of PAC solution of 10% concentration in waste water, PAC concentration is 10ppm in the waste water after dosing, adds 0.6kg of PAM solution of 0.2% concentration in waste water, and PAM concentration is 1ppm in the waste water after dosing. Wastewater enters the clarifier, and under the action of...

specific Embodiment 2

[0054] 1,000kg of desulfurization wastewater enters the regulating tank, and the ion concentration in the wastewater is detected, CL ions are 21,000mg / L, magnesium ions are 8,100mg / L, and sulfate ions are 7,200mg / L.

[0055] Add 133kg of calcium hydroxide solution of 5% concentration in reaction tank, reaction generates calcium sulfate precipitation, removes the sulfate radical ion in waste water. Hydroxide in calcium hydroxide solution combines with magnesium ions to form magnesium hydroxide precipitate. Add 72 kg of 30% concentration of sodium hydroxide solution in the regulating tank, adjust the wastewater pH to 12, and eliminate all magnesium ions.

[0056] Add 0.2kg of PAC solution of 10% concentration in waste water, PAC concentration is 10ppm in the waste water after dosing, adds 0.8kg of PAM solution of 0.2% concentration in waste water, and PAM concentration is 1ppm in the waste water after dosing. Wastewater enters the clarifier, and under the action of flocculants ...

specific Embodiment 3

[0060] 1000kg of desulfurization wastewater enters the regulating tank, and the ion concentration in the wastewater is detected, CL ions are 25000mg / L, magnesium ions are 10200mg / L, and sulfate ions are 7300mg / L.

[0061] Add 135kg of calcium hydroxide solution of 5% concentration in reaction pool, reaction generates calcium sulfate precipitation, removes the sulfate radical ion in waste water. Hydroxide in calcium hydroxide solution combines with magnesium ions to form magnesium hydroxide precipitate. Add 95kg of 30% concentration of sodium hydroxide solution in the regulating tank, adjust the wastewater pH to 12, and eliminate all magnesium ions.

[0062] Add 0.2kg of PAC solution of 10% concentration in waste water, PAC concentration is 10ppm in the waste water after dosing, adds 0.8kg of PAM solution of 0.2% concentration in waste water, and PAM concentration is 1ppm in the waste water after dosing. Wastewater enters the clarifier, and under the action of flocculants and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com