Universal preparation method of reduced graphene oxide-based asymmetric composite membrane

A graphene-based composite membrane technology, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc. The potential application range of the membrane and other issues can be avoided to avoid aggregation, facilitate the preparation of membranes, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A general preparation method for a reduced graphene oxide-based asymmetric composite membrane, comprising the following steps:

[0038] (1) Prepare graphene oxide-based mixed solution a, which includes not only graphene oxide, but also polymers, organic nanomaterials, inorganic nanomaterials, metal nanomaterials, and precursors for preparing inorganic or metal nanomaterials one or more of the

[0039](2) The graphene oxide-based mixed solution a obtained in step (1) is prepared into a graphene oxide-based composite film by a certain method such as vacuum filtration, spin coating, drop coating, scraping, coating, electrospinning, etc.;

[0040] (3) Another solution or mixed solution b is prepared, and the graphene oxide base prepared in step (2) is prepared in a certain way such as vacuum filtration, spin coating, drip coating, scraping coating, coating, electrospinning, etc. Prepare another membrane containing different material components on the surface of the composi...

Embodiment 1

[0061] Step (1): Disperse 0.5 g of graphene oxide in 100 mL of water, stir for 8 hours, and sonicate for 20 minutes to obtain a 5 mg / mL graphene oxide dispersion;

[0062] Step (2): Dissolving 1 g of polyvinyl alcohol in 100 mL of water to prepare a 10 mg / mL polyvinyl alcohol solution;

[0063] Step (3): Use the graphene oxide dispersion prepared in step (1) and the polyvinyl alcohol solution and water prepared in step (2) to reconstitute 1mg / mL graphene oxide and 0.25mg / mL graphene oxide according to a certain proportion. mL of polyvinyl alcohol mixture;

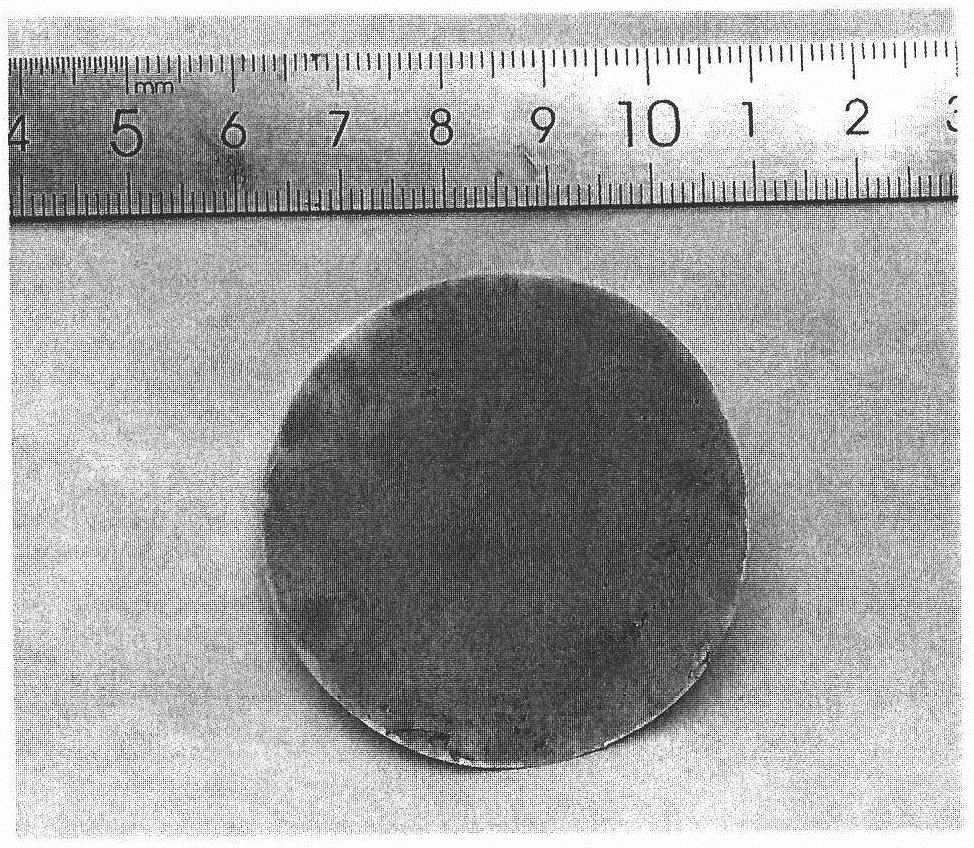

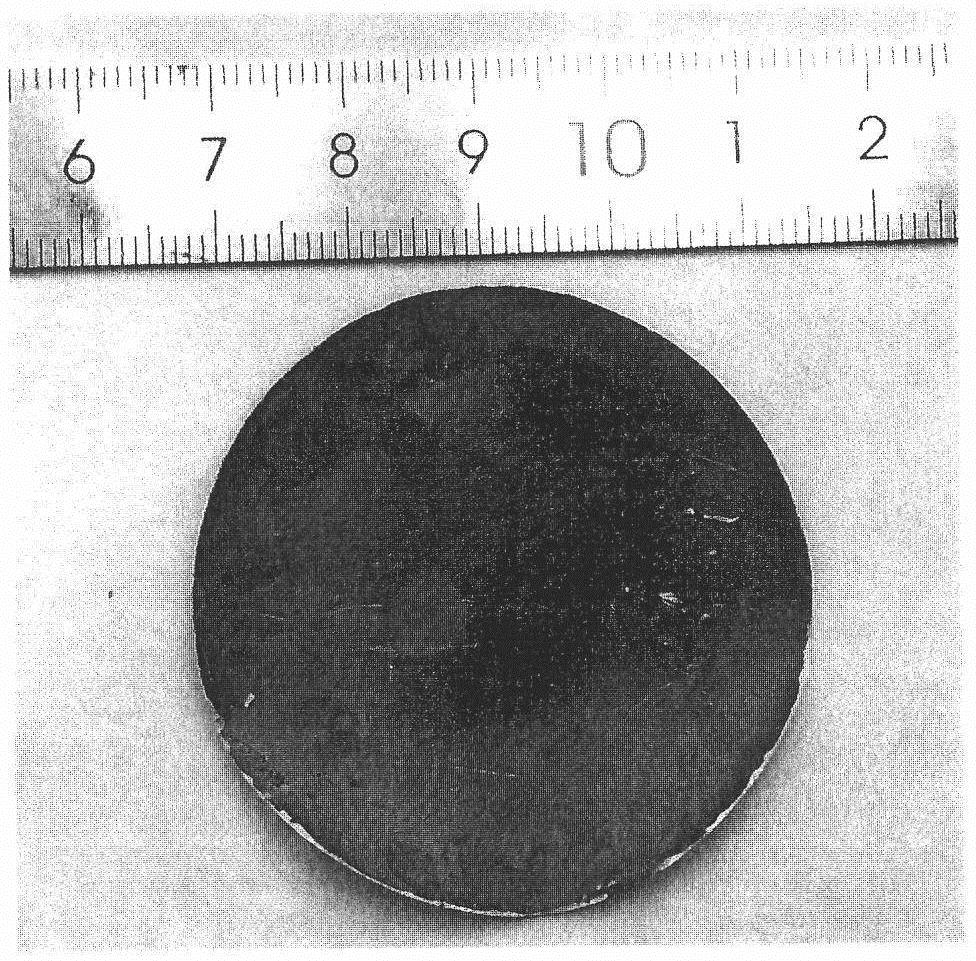

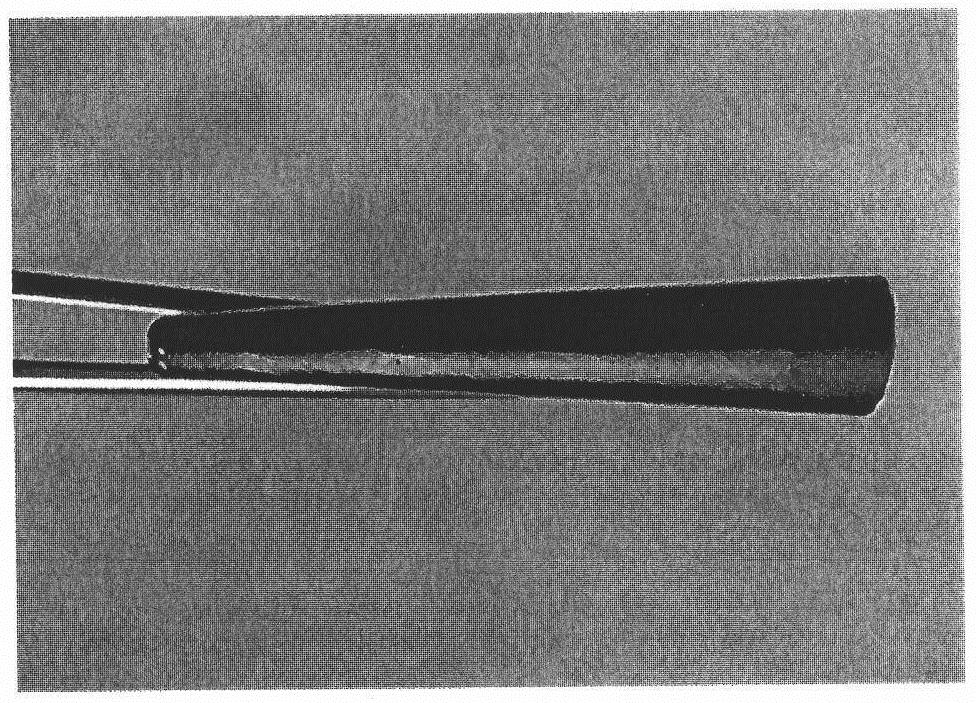

[0064] Step (4): Coat 0.4 mL of the graphene oxide / polyvinyl alcohol mixture prepared in step (3) on a PVDF filter membrane modified by a hydrophilic polymer with a diameter of about 5 cm, and dry at room temperature to prepare a oxidized Graphene / polyvinyl alcohol composite film;

[0065] Step (5): Take 20 mL of the 5 mg / mL graphene oxide solution prepared in step (1), then add carbon nanotubes with 1 / 20 of the graphene ...

Embodiment 2

[0069] Step (1): Dispersing 1 g of graphene oxide in 200 mL of water, stirring for 10 h, and ultrasonicating for 5 min to obtain a graphene oxide dispersion;

[0070] Step (2): Add 0.01 g of carbon nanotubes, 10 mL of ethylenediamine, and 5 g of sodium ascorbate to the graphene oxide dispersion obtained in step (1), stir for 1 h, and ultrasonicate for 10 min, take out 0.2 mL and dilute it into 100 mL of water, and ultrasonically After 5 minutes, the film was formed by suction filtration on a hydrophilic polymer-modified PVDF filter membrane with a diameter of about 4 mm to obtain a graphene oxide / carbon nanotube composite membrane;

[0071] Step (3): Prepare 20 mL of 5 mg / mL graphene oxide dispersion, and add 5 mg of graphene to prepare graphene oxide / graphene dispersion;

[0072] Step (4): After redispersing 0.1mL of graphene oxide / graphene prepared in step (3) in 100mL of water, the graphene oxide / carbon nanotube composite film was formed in step (2) by vacuum filtration Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com