Preparation method of wormlike precipitated calcium carbonate

A precipitated calcium carbonate, worm-like technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., to achieve the effect of high specific surface area, high purity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

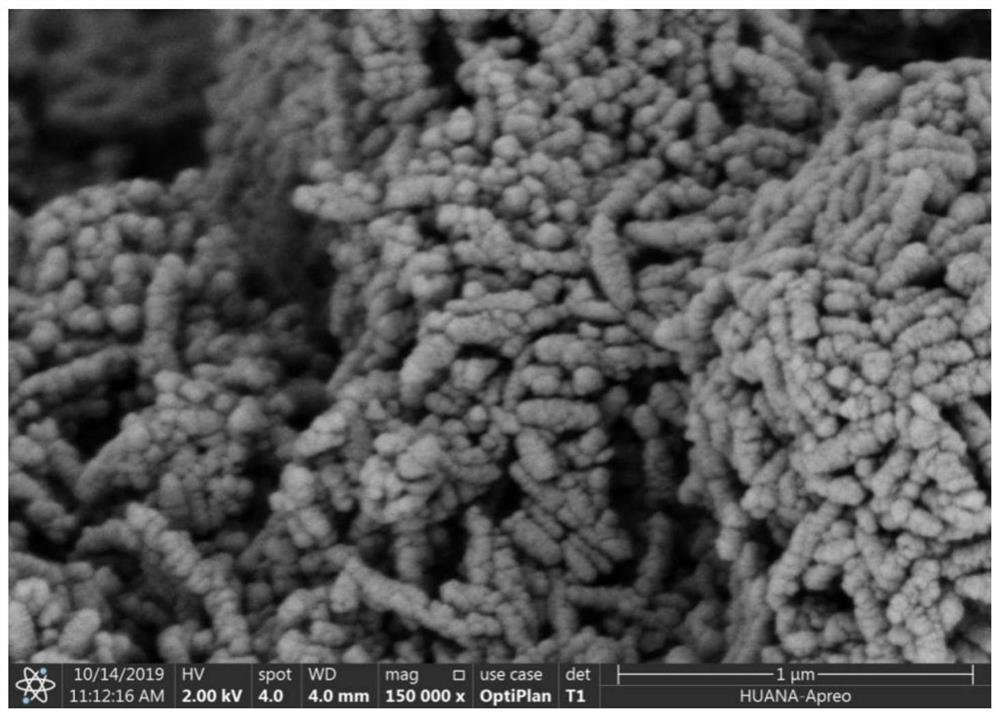

Image

Examples

Embodiment 1

[0032] A preparation method for worm-like precipitated calcium carbonate, comprising the steps of:

[0033] (1) After the quicklime is digested and reacted, the obtained milk of lime is adjusted to a specific gravity of 1.050 to obtain a calcium hydroxide suspension;

[0034] (2) Take 15 kg of calcium hydroxide suspension, add 0.1 mol magnesium chloride and 0.2 mol strontium chloride to it, make a solution with a cation molar concentration of 1 mol / L as a crystal form control agent, stir and mix evenly, and then add the carbonization tower, Control the stirring rate to 20Hz, the carbonization start temperature is 21.0°C, pass a mixed gas of carbon dioxide with a concentration of 30% into the suspension, and the flow rate is 2.0m 3 / h until the pH drops to 9.0 to stop carbonation and obtain a PCC suspension;

[0035] (3) Add a phosphoric acid solution with a mass concentration of 5% to the PCC suspension at a rate of 220ml / min until the pH drops to 7.0, terminate the reaction,...

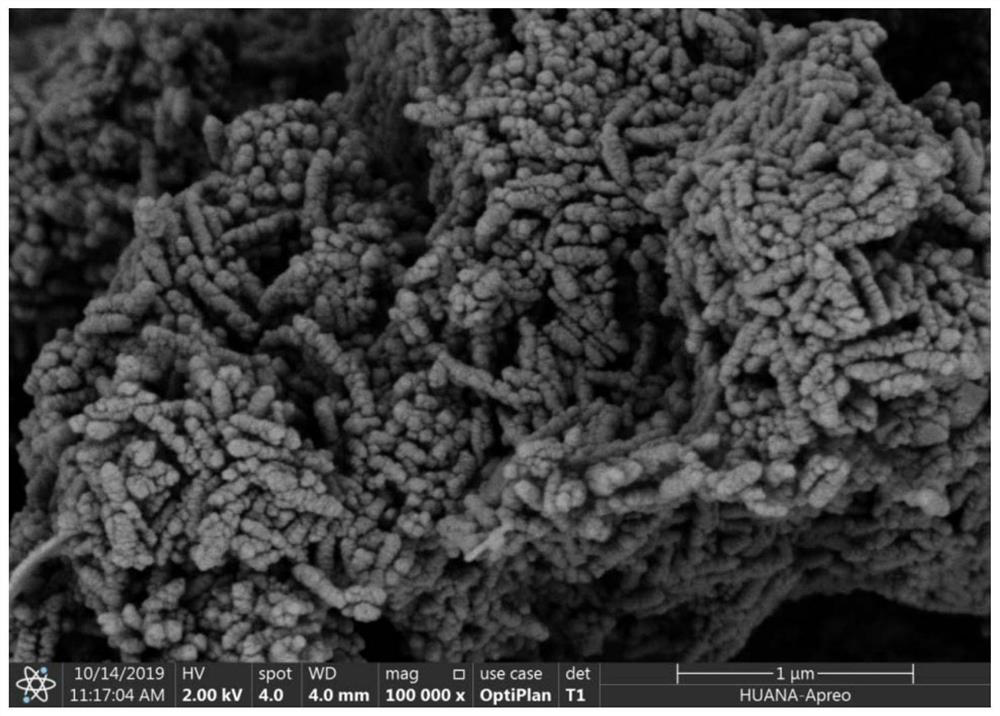

Embodiment 2

[0038] A preparation method for worm-like precipitated calcium carbonate, comprising the steps of:

[0039] (1) After the quicklime is digested and reacted, the obtained milk of lime is adjusted to a specific gravity of 1.060 to obtain a calcium hydroxide suspension;

[0040](2) Take 15 kg of calcium hydroxide suspension, add 0.3 mol of magnesium oxide to it, make a solution with a concentration of 3 mol / L as a crystal form control agent, stir and mix evenly, then add to the carbonization tower, control the stirring rate to 20 Hz, and carbonize The initial temperature is 23.0°C, and a mixed gas of carbon dioxide with a concentration of 31% is introduced into the suspension with a flow rate of 2.0m 3 / h until the pH drops to 9.0 to stop carbonation and obtain a PCC suspension;

[0041] (3) Add a phosphoric acid solution with a mass concentration of 5% to the PCC suspension at a rate of 250ml / min until the pH drops to 7.0, terminate the reaction, let it stand for 20 minutes, an...

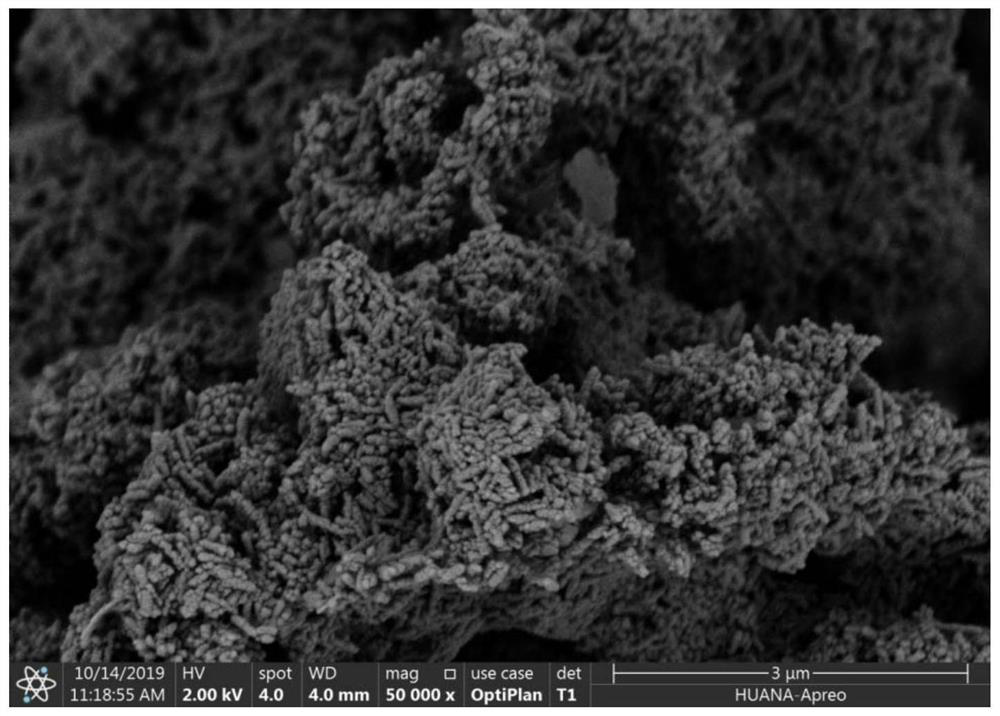

Embodiment 3

[0044] A preparation method for worm-like precipitated calcium carbonate, comprising the steps of:

[0045] (1) After the quicklime is digested, the milk of lime obtained is adjusted to a specific gravity of 1.065 to obtain a calcium hydroxide suspension;

[0046] (2) Take 15kg of calcium hydroxide suspension, add 0.4mol magnesium bicarbonate and 0.1mol barium chloride to it, make a solution with a cation concentration of 5mol / L as a crystal form control agent, stir and mix evenly, and then add to the carbonization tower , the stirring rate is controlled at 20Hz, the carbonization start temperature is 24°C, and a mixed gas of carbon dioxide with a concentration of 33% is passed into the suspension with a flow rate of 2.2m 3 / h until the pH drops to 9.0 to stop carbonation and obtain a PCC suspension;

[0047] (3) Add a phosphoric acid solution with a mass concentration of 5% to the PCC suspension at a rate of 280ml / min until the pH drops to 7.0, stop the reaction, let it stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com