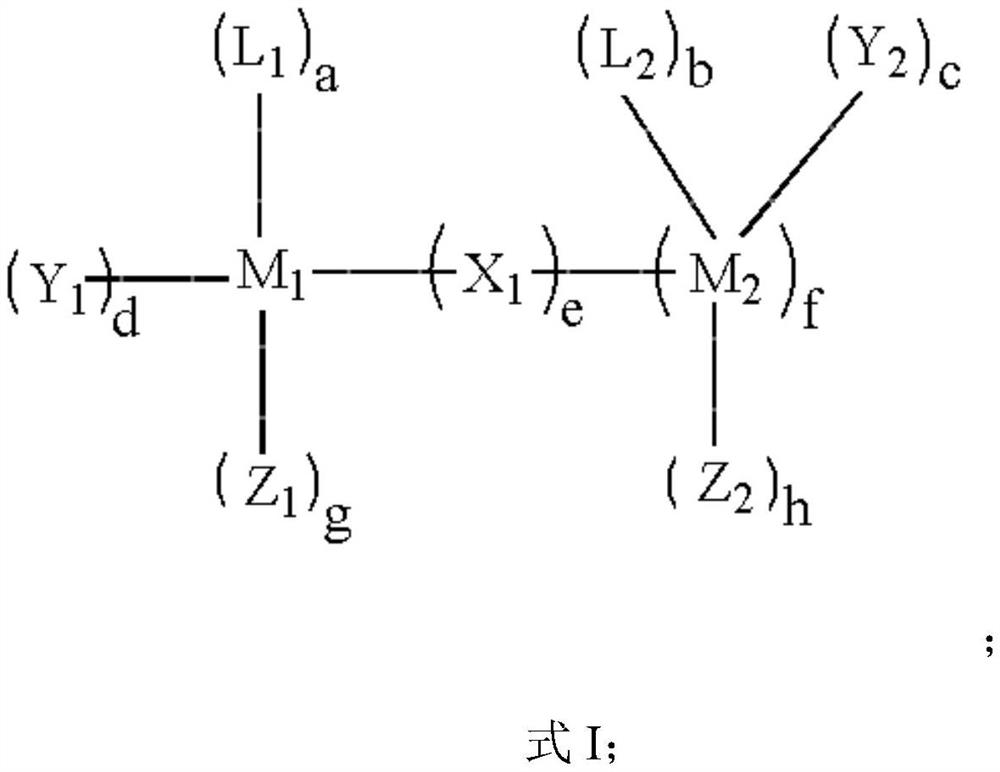

Phosphorus-nitrogen-containing flame retardant with hydroxyl group as well as preparation method and application of flame retardant

A flame retardant, hydroxyl technology, applied in the field of phosphorus nitrogen-containing flame retardants and their preparation, can solve the problems of small molecule precipitation and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

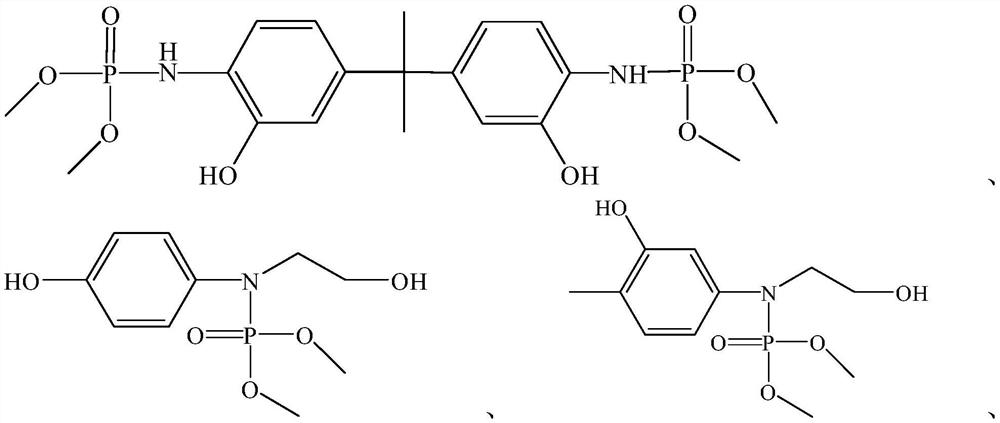

[0070] A phosphorus and nitrogen-containing flame retardant with hydroxyl, the structure is as follows:

[0071]

[0072] The preparation method is as follows:

[0073] Put 1mol diethanolamine, 1mol hydroxymethyl dimethyl phosphite, 500mL ethanol, 0.1mol sodium hydroxide and 0.1g DMAP into a three-port 2000mL glass reactor with a stirring device, heat up to ethanol reflux, and react for 24 hours under stirring. After the completion, wash with water until neutral, and remove impurities to obtain the phosphorus-nitrogen-containing flame retardant with the above structure.

[0074] 1 H NMR (400MHz, DMSO-d6): δ=4.26-4.28(t,2H,-OH),3.63-3.66(m,4H,-N-CH 2 -C H 2 -OH),3.47-3.49(d,6H,-P-O-CH 3 ),2.82-2.84(d,2H,-P-C H 2 -)2.53-2.55(t,4H,-N-C H 2 -CH 2 -OH).

preparation example 2

[0076] A phosphorus and nitrogen-containing flame retardant with hydroxyl, the structure is as follows:

[0077]

[0078] The preparation method is as follows:

[0079] Put 1mol 2,2-bis(4-hydroxy-3-aminophenyl)propane, 2.1mol trimethyl phosphate, 200mL DMF, 0.1mol sodium hydroxide and 0.1g DMAP into a three-port 500mL glass reactor with stirring device , heated to ethanol reflux, reacted for 24 hours under stirring, washed with water until neutral after the reaction, and removed impurities to obtain the phosphorus-nitrogen-containing flame retardant with the above structure.

[0080] 1 H NMR (400MHz, DMSO-d6): δ=9.77-9.80(s,2H,-OH),6.51-6.60(dd,6H,ph-H),4.38-4.42(s,2H,-NH-), 3.80-3.84(d,12H,-P-O-CH 3 ),1.65-1.72(s,6H,-CH 3 ).

preparation example 3

[0082] A phosphorus and nitrogen-containing flame retardant with hydroxyl, the structure is as follows:

[0083]

[0084] The preparation method is as follows:

[0085] Put 1mol 4-(2-hydroxyethylamino)phenol, 2.1mol trimethyl phosphate, 200mL DMF, 0.1mol sodium hydroxide and 0.1g DMAP into a three-port 500mL glass reactor with stirring device, heat up to ethanol reflux, React under stirring for 24 hours, wash with water until neutral after the reaction, and remove impurities to obtain the phosphorus-nitrogen-containing flame retardant with the above structure.

[0086] 1 H NMR (400MHz, DMSO-d6): δ=9.39-9.41 (s, 1H, ph-OH), 6.72-6.64 (m, 2H, ph-H close to -OH), 6.50-6.42 (m, 2H ,ph-H),4.64-4.68(t,1H,-OH),3.76-3.80(d,6H,-P-O-CH 3 ),3.55-3.60(m,2H,-CH 2 -OH),3.24-3.27(t,2H,-N-CH 2 -).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com