A kind of preparation method of nano manganese carbide material

A manganese carbide and nanotechnology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems that do not involve nano manganese carbide materials, and achieve excellent compatibility, good shape retention, and resistivity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

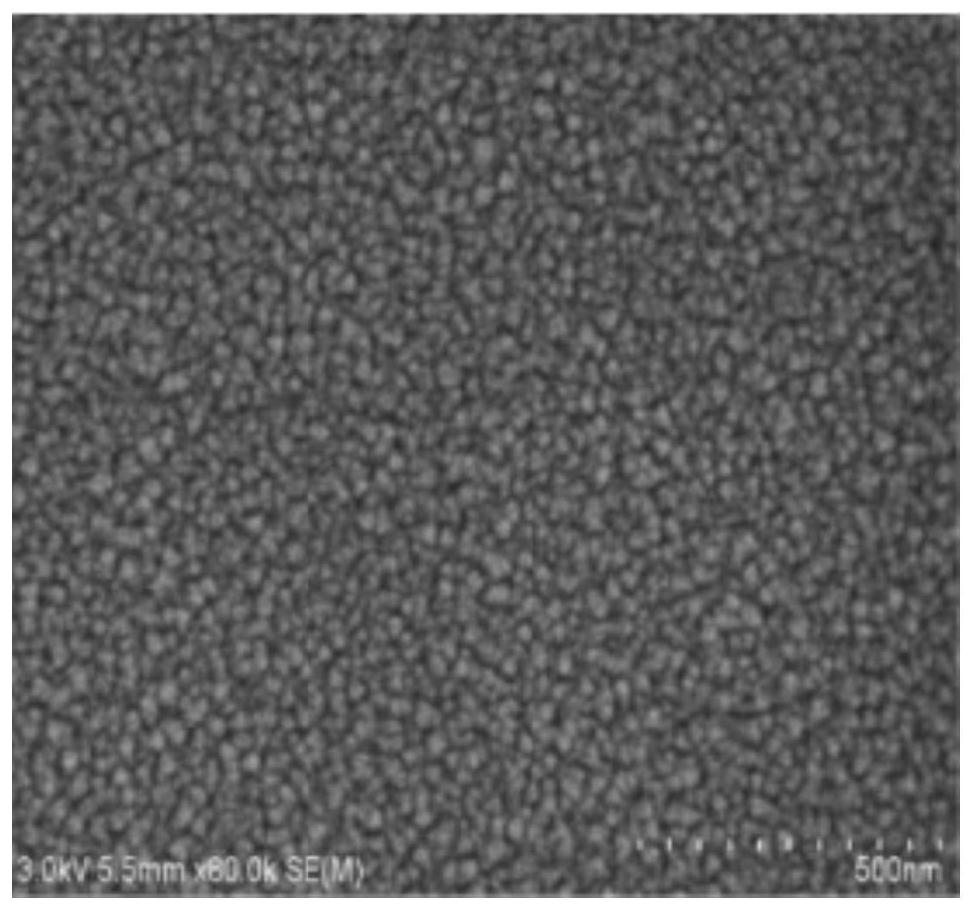

Image

Examples

Embodiment 1

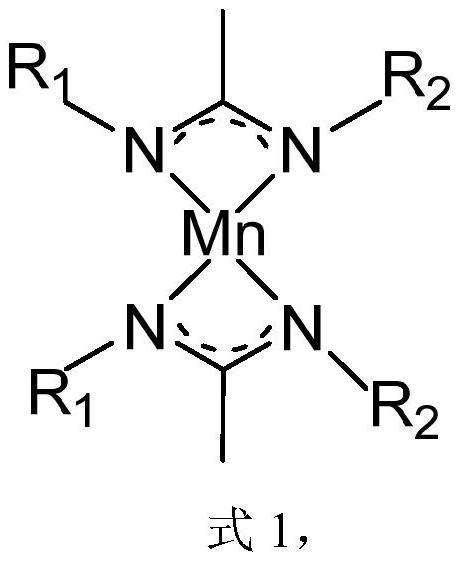

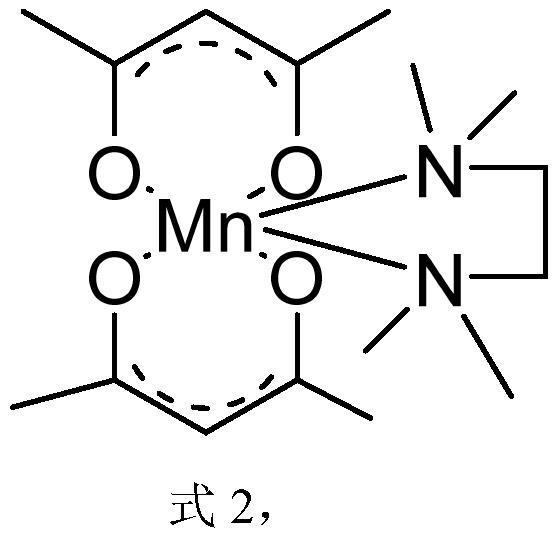

[0037] With [di(N,N'-di-sec-butylethylamidine) manganese (II)] (formula 1, R, R 1 All are sec-butyl) as manganese source, the method for the ALD in situ growth nano manganese carbide material of carbon source with formaldehyde, comprises following process:

[0038] (1) with SiO 2 As the substrate, bis(N,N'-di-sec-butylethylamidine) manganese (II) was heated to 85°C to vaporize it, and high-purity nitrogen was used as the carrier gas, and the gas phase bis(N,N '-di-sec-butylethylamidine) manganese (II), the carrier gas flow rate is 10 sccm, under vacuum conditions, the pulse time is 9s, and the deposition temperature is 300 ° C;

[0039](2) After completing a pulse, use high-purity nitrogen for purging treatment, and the purging time is 60s; then high-purity nitrogen is used as the carrier gas, and the carrier gas flow rate is 20 sccm, and formaldehyde is introduced in the form of pulses, and the pulse time is 1s;

[0040] (3) After completing a pulse, use high-purity nitroge...

Embodiment 2

[0043] With [di(N,N'-di-sec-butylethylamidine) manganese (II)] (formula 1, R, R 1 All are isopropyl) as manganese source, the method for the ALD in situ growth nano manganese carbide material of carbon source with acetaldehyde, comprises following process:

[0044] (1) Using silicon as the substrate, heat the manganese source to 80°C to vaporize it, use high-purity nitrogen as the carrier gas, and feed the gas-phase manganese source, the flow rate of the carrier gas is 20 sccm, and the pulse time is 10s under vacuum conditions. The deposition temperature is 280°C;

[0045] (2) After completing a pulse, use high-purity nitrogen for purging treatment, the purging time is 50s; heat the carbon source acetaldehyde to gasify it, use high-purity nitrogen as the carrier gas, and the flow rate of the carrier gas is 200 sccm, in the form of pulses Pass through acetaldehyde, the pulse time is 3s;

[0046] (3) After completing a pulse, use high-purity nitrogen to purge, and the purge ti...

Embodiment 3

[0049] With [di(N-isopropyl-N'-sec-butylethylamidine) manganese (II)] (formula 1, R, R 1 Respectively isopropyl and sec-butyl) as manganese source, with propionaldehyde as carbon source, including the following process:

[0050] (1) Using silicon nitride as the substrate, heat the manganese source to 90°C to vaporize it, and use high-purity nitrogen as the carrier gas to feed the gas-phase manganese source. The flow rate of the carrier gas is 30 sccm. Under vacuum conditions, the pulse time is 7s, and the deposition temperature is 260°C;

[0051] (2) After completing a pulse, use high-purity nitrogen to purge, and the purge time is 32s; heat the carbon source propionaldehyde to 33°C to vaporize it, use high-purity nitrogen as the carrier gas, and the flow rate of the carrier gas is 120sccm, Pass propionaldehyde in the form of pulse, the pulse time is 4s;

[0052] (3) After completing a pulse, use high-purity nitrogen to purge, and the purge time is 26s.

[0053] The above s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com