Kitchen waste disposal system

A food waste and treatment system technology, which is applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of high investment in equipment, high energy consumption of the combustion method, and cure the symptoms but not the root cause, so as to achieve simple process flow and improve treatment effect , The effect of saving civil construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

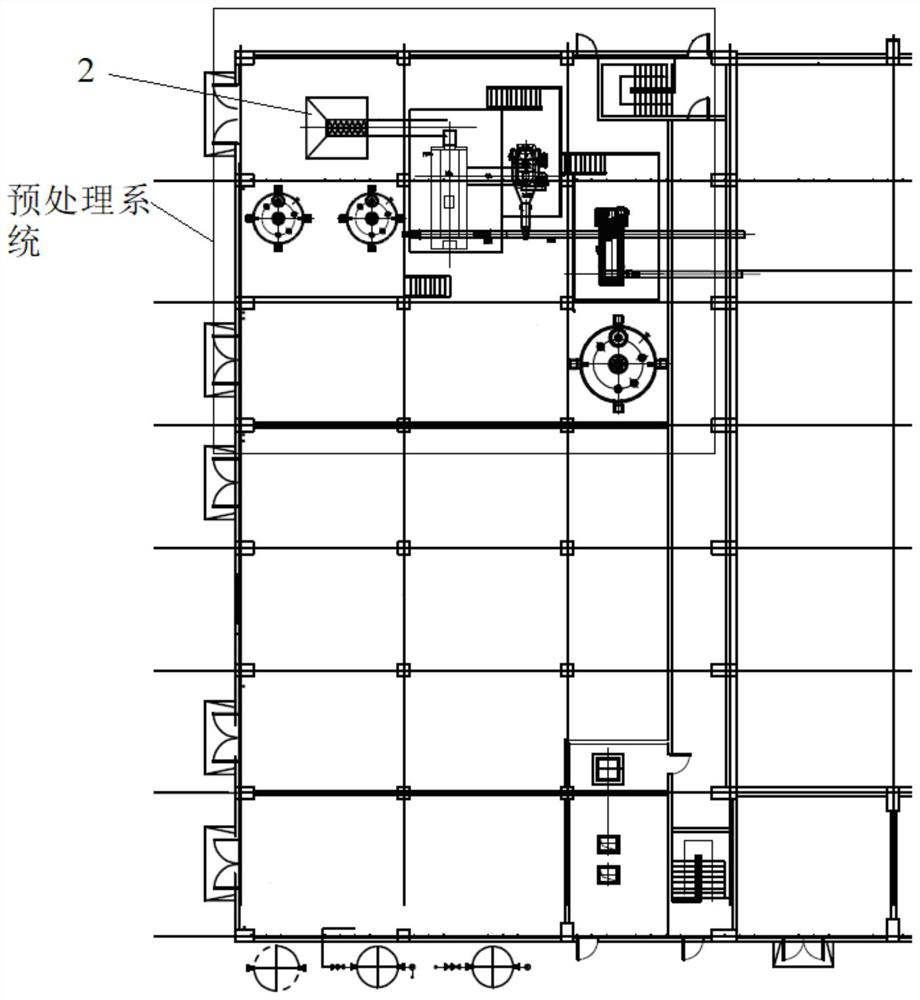

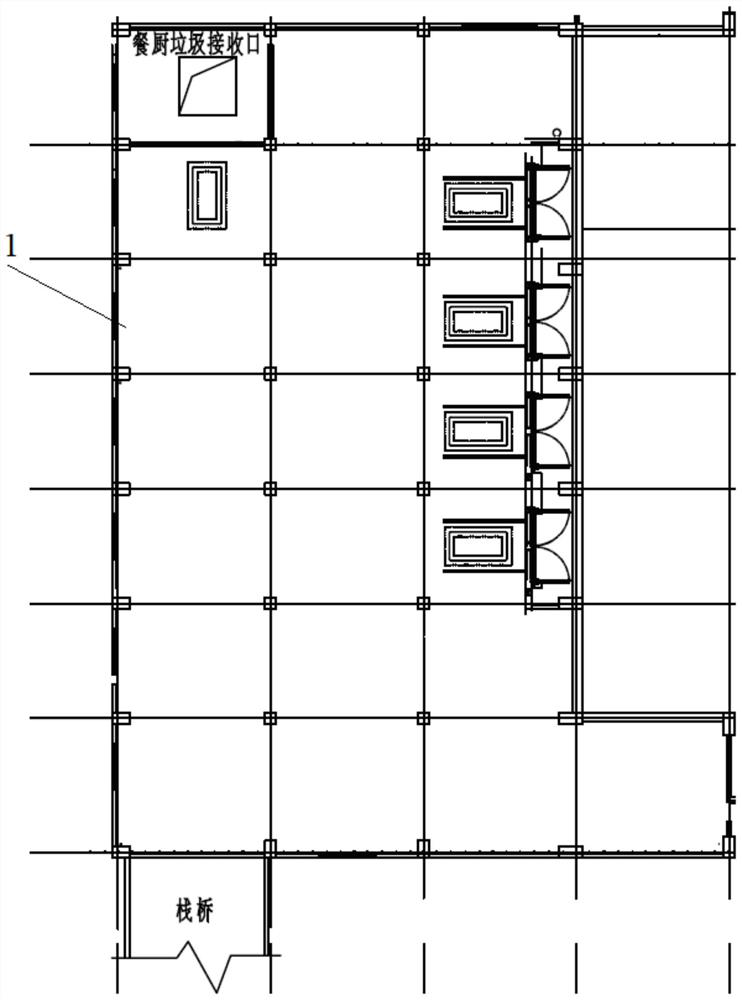

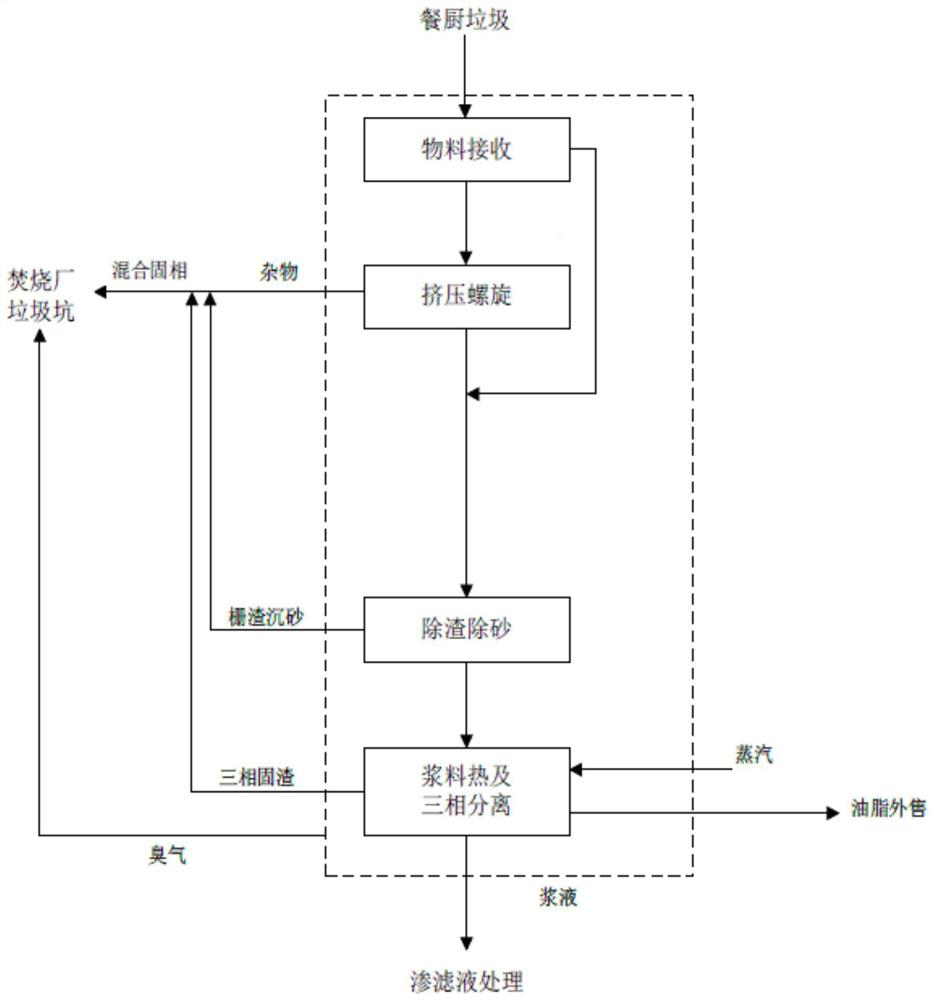

[0019] Such as figure 1 with figure 2 As shown, the present invention provides a food waste treatment system, including a garbage trestle bridge used to guide food waste to the unloading hall of the domestic waste incineration power plant, arranged in the unloading hall and used to receive incoming unloading A receiving hopper for the food waste in the material hall and a pretreatment system for receiving the food waste from the receiving hopper and treating the food waste, the pretreatment system is arranged under the discharge hall.

[0020] Specifically, as figure 1 with figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com