A kind of carbon fluoride-manganese dioxide metal battery electrolyte and battery containing the same

A manganese dioxide and metal battery technology is applied in the fields of lithium carbon fluoride-manganese dioxide batteries and carbon fluoride-manganese dioxide metal batteries, and can solve problems such as poor high and low temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

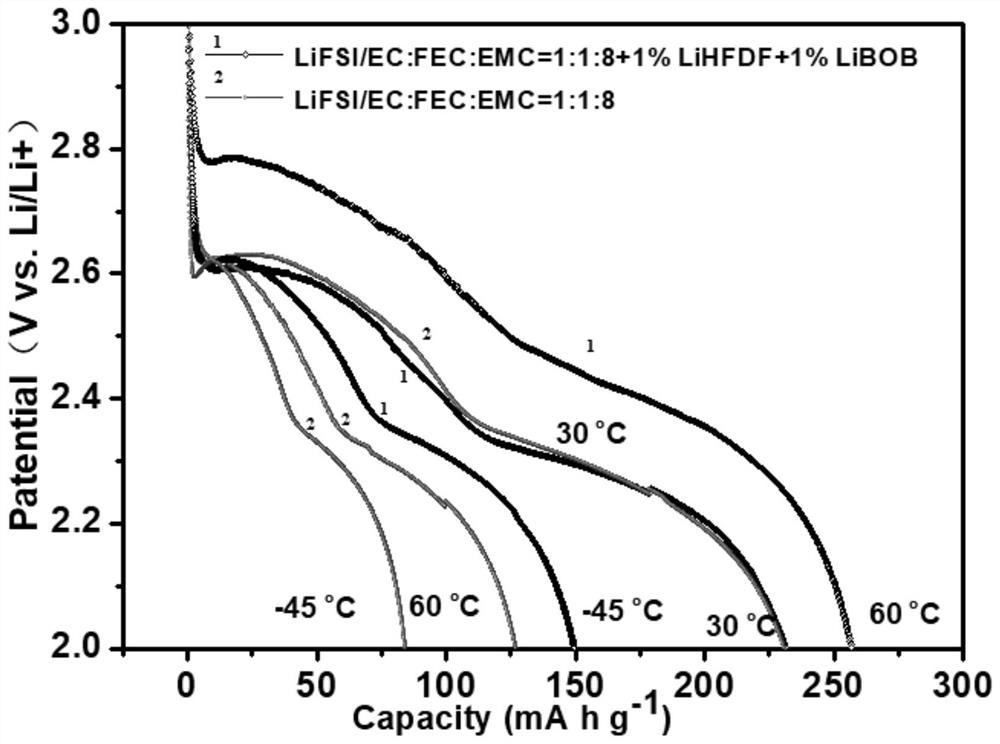

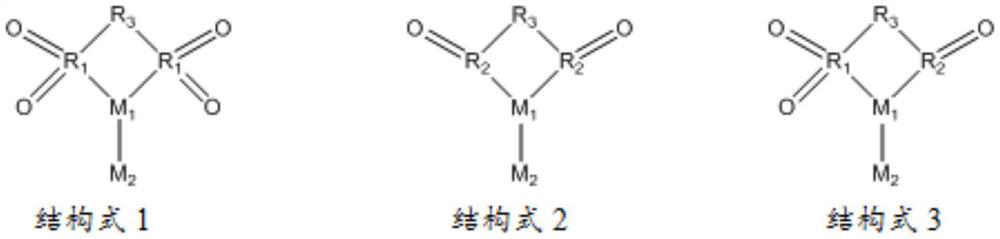

[0057] Preparation of the electrolyte of Example 1: 1M LiN (SO 2 f) 2 (LiFSI) dissolved in the solvent of vinylene carbonate (EC): fluoroethylene carbonate (FEC): ethyl methyl carbonate (EMC) = 1:1:8, and then add 1% of the first additive 1,1 ,2,2-tetrafluoroethane-1,3-bissulfonic acid cyclic imide lithium (LiHFDF), its chemical formula is as follows:

[0058]

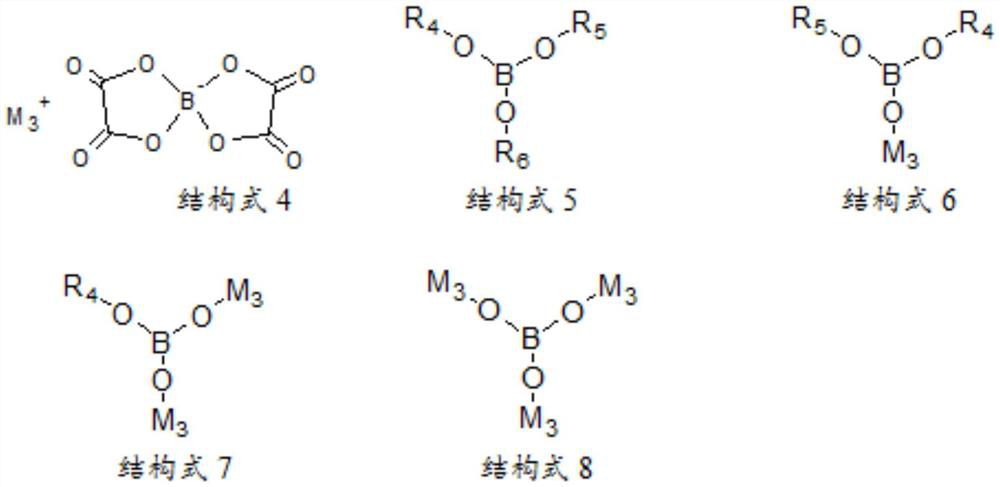

[0059] The electrolyte is also added with 1% of the second additive lithium borate (LiBOB) at the same time, and finally the required electrolyte is prepared.

[0060] The preparation of the electrolytes of Examples 2-3 is similar to that of Example 1, except that different contents of LiHFDF and LiBOB are used to study the effect of the amount of LiHFDF and LiBOB on the electrochemical performance of the battery.

[0061] The preparation of the electrolytes of Examples 4-6 is similar to that of Example 1, except that the solvent uses FEC instead of EC+FEC, and uses different contents of LiBOB to study the effect ...

Embodiment 24

[0064] The type and dosage of the electrolyte additive in Example 24 are the same as those in Example 1, except that the electrolyte does not contain FEC, so as to study the effect of FEC on the electrolyte system.

Embodiment 25

[0065] The type and amount of the electrolyte additive in Example 25 are the same as in Example 1, and the lithium salt LiPF is used. 6 Instead of lithium salt LiFSI, it is used to study the effect of lithium salt on electrolyte system.

[0066] The preparations of Comparative Examples 1-3 were similar to those of Comparative Example 1, except that Comparative Examples 1-3 did not contain the first additive LiHFDF and / or the second additive LiBOB to study the effect of LiHFDF and LiBOB on the battery performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com