A kind of antibacterial home clothes fabric and its production process and application

A production process and fabric technology, applied in the field of clothing, can solve the problems of poor hygroscopicity, easy to generate static electricity, and difficult to take care of, and achieve the effects of increasing permeability, adsorbing human body odor, and improving connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

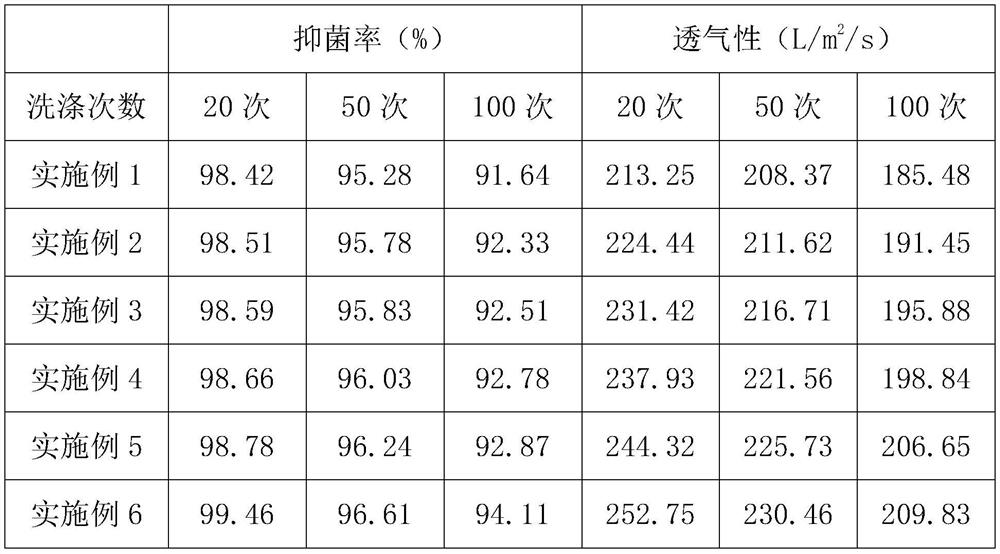

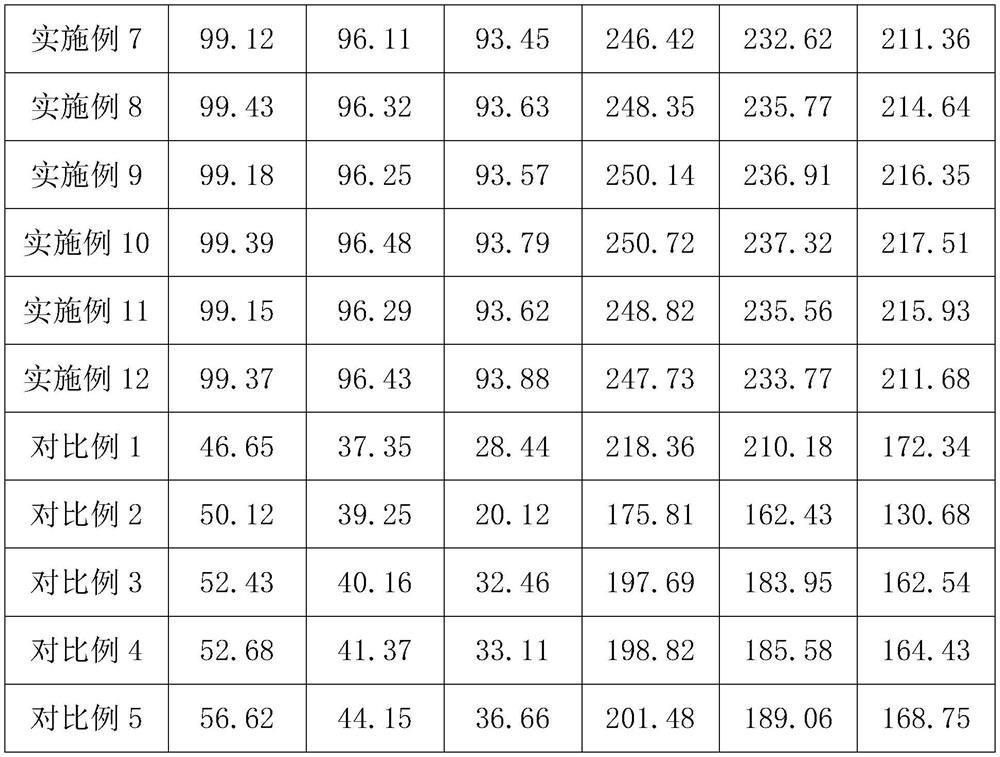

Examples

Embodiment 1

[0037] An antibacterial household clothing fabric, which includes a base layer, an antibacterial layer and a surface layer from the inside to the outside, the base layer is woven from cotton fibers, the antibacterial layer is formed by coating the base layer with antibacterial liquid, and the surface layer is made of polyamide fiber, cotton fiber , polyester blended, of which polyamide fiber accounts for 25%, cotton fiber accounts for 30%, polyester accounts for 45%;

[0038] Wherein the preparation of antibacterial liquid comprises the following steps:

[0039] 1) Add 20kg of polyurethane resin and 10kg of polyetheramine into the reactor, raise the temperature of the reactor to 170°C, and then stir for 30 minutes;

[0040] 2) After the temperature of the system in step 1) drops to 140°C, add 12kg of bamboo charcoal powder, 8kg of chitosan oligosaccharide, 3kg of organic montmorillonite, 4kg of nano-titanium dioxide, and 2kg of CTAB to step 1) and continue stirring for 60 minu...

Embodiment 2

[0047] An antibacterial household clothing fabric, which includes a base layer, an antibacterial layer and a surface layer from the inside to the outside, the base layer is woven from cotton fibers, the antibacterial layer is formed by coating the base layer with antibacterial liquid, and the surface layer is made of polyamide fiber, cotton fiber , polyester blended, of which polyamide fiber accounts for 25%, cotton fiber accounts for 30%, polyester accounts for 45%;

[0048] Wherein the preparation of antibacterial liquid comprises the following steps:

[0049] 1) Add 23kg of polyurethane resin and 8kg of polyetheramine into the reactor, raise the temperature of the reactor to 180°C, and then stir for 25 minutes;

[0050] 2) After the temperature of the system in step 1) drops to 150°C, add 10kg of bamboo charcoal powder, 4kg of chitosan oligosaccharide, 4kg of organic montmorillonite, 5kg of nano-titanium dioxide, and 3kg of CTAB to step 1) and continue stirring for 50 minut...

Embodiment 3

[0057] An antibacterial household clothing fabric, which includes a base layer, an antibacterial layer and a surface layer from the inside to the outside, the base layer is woven from cotton fibers, the antibacterial layer is formed by coating the base layer with antibacterial liquid, and the surface layer is made of polyamide fiber, cotton fiber , polyester blended, of which polyamide fiber accounts for 25%, cotton fiber accounts for 30%, polyester accounts for 45%;

[0058] Wherein the preparation of antibacterial liquid comprises the following steps:

[0059] 1) Add 25kg of polyurethane resin and 5kg of polyetheramine into the reactor, raise the temperature of the reactor to 200°C, and then stir for 20 minutes;

[0060] 2) After the temperature of the system in step 1) drops to 160°C, add 15kg of bamboo charcoal powder, 6kg of chitosan oligosaccharide, 5kg of organic montmorillonite, 3kg of nano-titanium dioxide, and 2.2kg of CTAB to step 1) and continue stirring for 30 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com