Multifunctional thin thermal insulation material and use method

A thermal insulation and multi-functional technology, applied in the field of thermal insulation materials, can solve the problem of not being able to absorb electromagnetic radiation, etc., and achieve the effects of convenient construction, repairing small cracks on the wall, and easy painting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

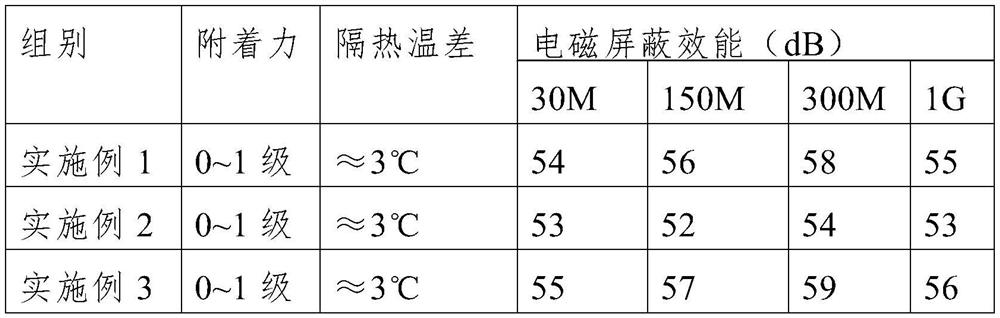

Examples

Embodiment 1

[0029] This embodiment provides a kind of multifunctional thin-body thermal insulation material, calculates by mass parts ratio, comprises 15 parts of diatomites, 5 parts of nano-zirconia, 5 parts of glass microspheres (3M), 3 parts of airgel (gas phase Silica), 10 parts of expanded vermiculite, 20 parts of HPMC, 3 parts of polycrystalline alumina fiber, 2 parts of nano-platinum powder, 2 parts of conductive micropowder (commercialization), 20 parts of white cement, 10 parts of Wacker rubber powder, 12 parts of PVB adhesive, 1.5 parts of modified polycarboxylate XT-2000 dispersant.

[0030] Mix the above-mentioned powders in a trough, and mix them evenly by microwave vibration. Before use, add water with 50% of the total mass of the powder, disperse evenly in an 800rpm high-speed ball mill for 20 minutes, and discharge the slurry to be coated, which can be used for construction. If the slurry has been left to stand for a long time before use, ultrasonic vibration homogenizati...

Embodiment 2

[0032]The present embodiment provides a kind of multifunctional thin-body thermal insulation material, calculates by mass parts ratio, comprises 12 parts of diatomite, 4 parts of nano-zirconia, 4 parts of glass microspheres (3M), 2 parts of airgel (gas phase Silica), 6 parts of expanded perlite, 25 parts of HPMC, 4 parts of forsterite fiber, 2 parts of nano-platinum powder, 2 parts of conductive micropowder (commercialization), 20 parts of white cement, 10 parts of Wacker rubber powder, 12 1 part PVB adhesive, 1 part polycarboxylate om-361 dispersant.

[0033] Mix the above-mentioned powders in a trough, and mix them evenly by microwave vibration. Add water with 55% of the total mass of the powder before use, disperse evenly in an 800rpm high-speed ball mill for 20 minutes, and discharge to obtain a slurry to be coated.

Embodiment 3

[0035] This embodiment provides a kind of multifunctional thin-body thermal insulation material, calculates by mass parts ratio, comprises 20 parts of diatomites, 8 parts of nanometer zirconia, 8 parts of glass microspheres (3M), 5 parts of aerogels (gas phase Silica), 10 parts of expanded perlite, 30 parts of HEC, 4 parts of forsterite fiber, 3 parts of nano-platinum powder, 2.5 parts of conductive micropowder (commercialized), 25 parts of white cement, 12 parts of vinae rubber powder, 12 parts of PVB adhesive, 1 part of polycarboxylate om-361 dispersant.

[0036] Mix the above-mentioned powders in a trough, and mix them evenly by microwave vibration. Add water with 60% of the total mass of the powder before use, disperse evenly in an 800rpm high-speed ball mill for 20 minutes, and discharge to obtain a slurry to be coated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com