Preparation system and process of 1, 4-butanediol

A preparation system, butanediol technology, applied in the preparation of organic compounds, hydrogenation preparation, carbon-based compound preparation, etc., can solve the problems of inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

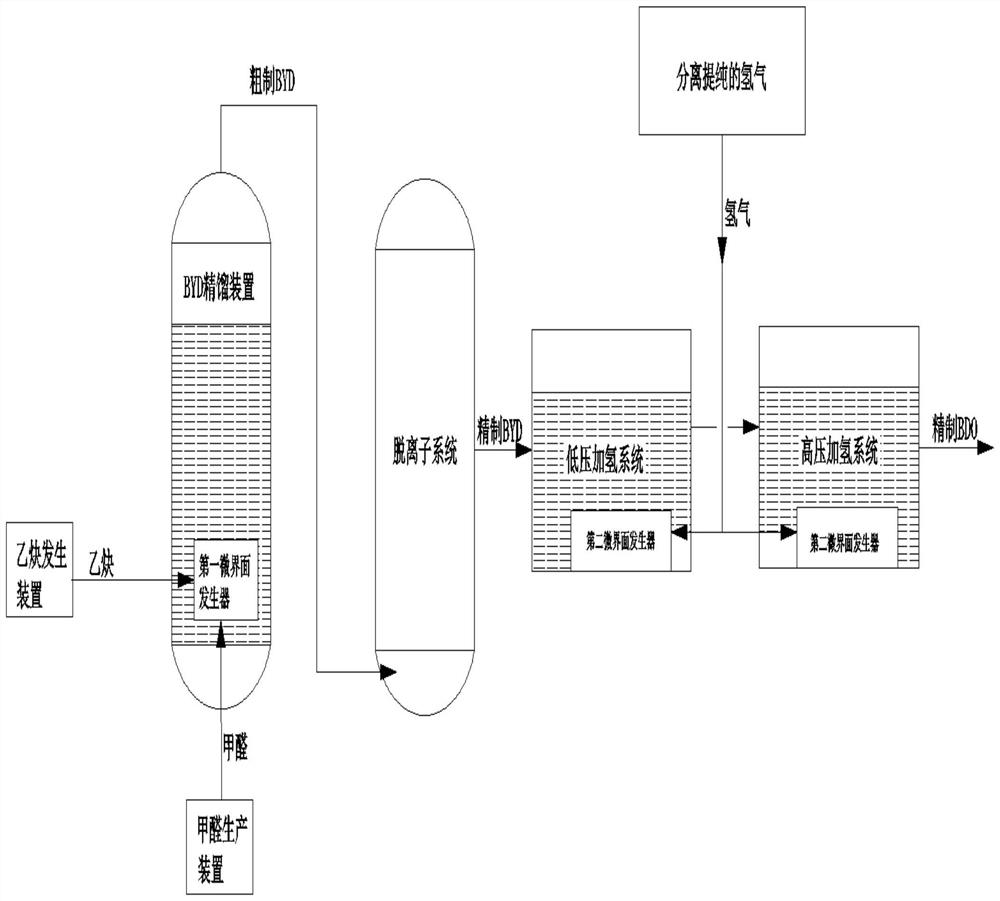

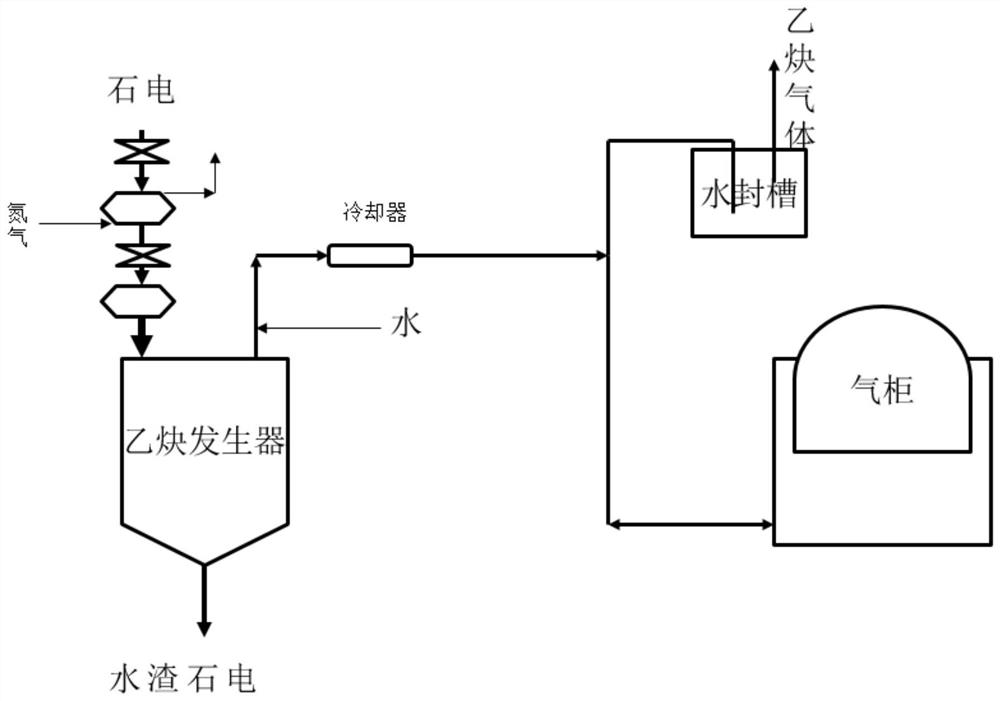

[0056] Step 1: Utilize the formaldehyde production device and the acetylene generation device to prepare formaldehyde and acetylene respectively;

[0057]Step 2: The formaldehyde and acetylene prepared in step 1 are subjected to acetylene aldehyde reaction in the reactor, and a catalyst is added in the acetylene aldehyde reaction to generate 1,4-butynediol; the catalyst in the acetylene aldehyde reaction is SiO 2 , the reaction temperature is 80 ℃, and the reaction pressure in the reactor is 1MPa;

[0058] Step 3: The 1,4-butynediol prepared in step 2 is subjected to hydrogenation reaction in an external reactor, the hydrogenation reaction is two-stage hydrogenation, and the first-stage hydrogenation reaction is carried out in a low-pressure hydrogenation system. It is a Ni-based catalyst, and the reaction pressure is 2MPa; the second-stage hydrogenation reaction is carried out in a high-pressure system, the catalyst used is a Pd-based catalyst, and the reaction pressure is 10...

Embodiment 2

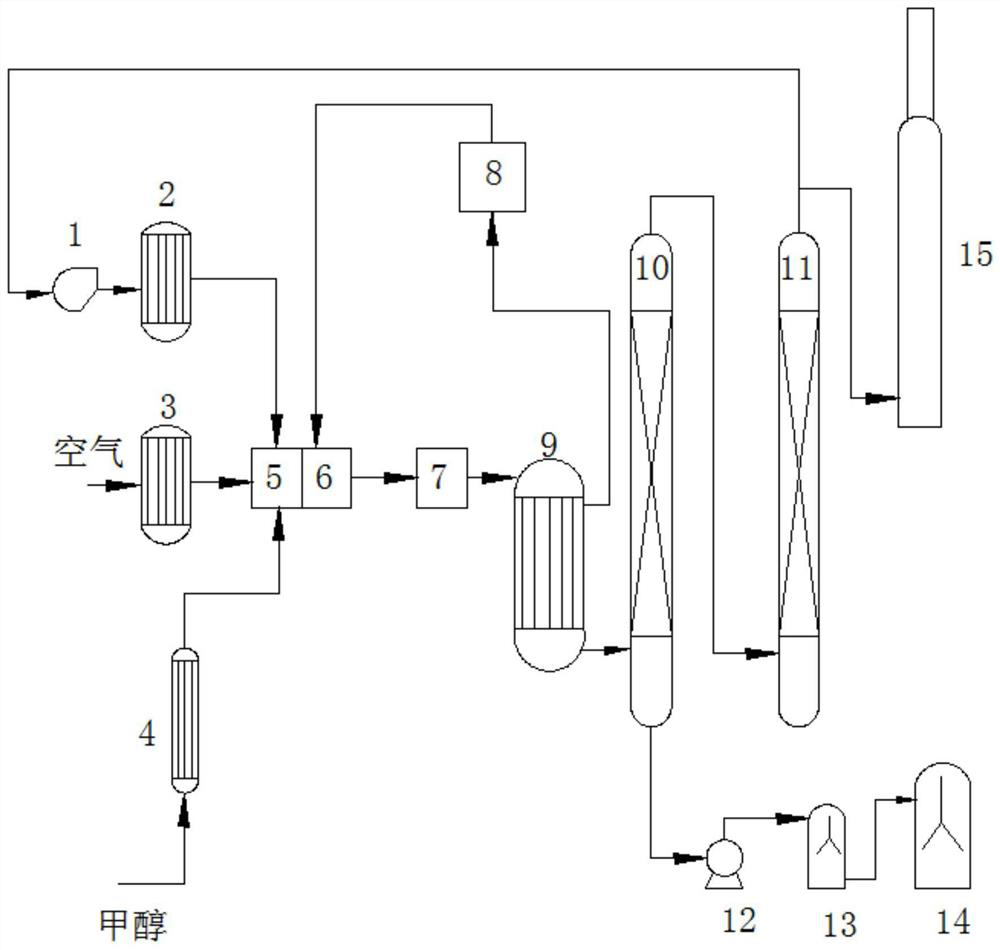

[0062] Step 1: Utilize the formaldehyde production device and the acetylene generation device to prepare formaldehyde and acetylene respectively;

[0063] Step 2: The formaldehyde and acetylene prepared in step 1 are subjected to acetylene aldehyde reaction in the reactor, and a catalyst is added in the acetylene aldehyde reaction to generate 1,4-butynediol; the catalyst in the acetylene aldehyde reaction is SiO 2 , the reaction temperature is 80 ℃, and the reaction pressure in the reactor is 1MPa;

[0064] Step 3: The 1,4-butynediol prepared in step 2 is subjected to hydrogenation reaction in an external reactor, the hydrogenation reaction is two-stage hydrogenation, and the first-stage hydrogenation reaction is carried out in a low-pressure hydrogenation system. It is a Ni-based catalyst, and the reaction pressure is 2MPa; the second-stage hydrogenation reaction is carried out in a high-pressure system, the catalyst used is a Pd-based catalyst, and the reaction pressure is 1...

Embodiment 3

[0068] Step 1: Utilize the formaldehyde production device and the acetylene generation device to prepare formaldehyde and acetylene respectively;

[0069] Step 2: The formaldehyde and acetylene prepared in step 1 are subjected to acetylene aldehyde reaction in the reactor, and a catalyst is added in the acetylene aldehyde reaction to generate 1,4-butynediol; the catalyst in the acetylene aldehyde reaction is SiO 2 , the reaction temperature is 80 ℃, and the reaction pressure in the reactor is 1MPa;

[0070] Step 3: The 1,4-butynediol prepared in step 2 is subjected to hydrogenation reaction in an external reactor, the hydrogenation reaction is two-stage hydrogenation, and the first-stage hydrogenation reaction is carried out in a low-pressure hydrogenation system. It is a Ni-based catalyst, and the reaction pressure is 2MPa; the second-stage hydrogenation reaction is carried out in a high-pressure system, the catalyst used is a Pd-based catalyst, and the reaction pressure is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com