Device system and method for ammonia-process flue gas desulfurization

A flue gas and ammonia process technology, which is applied in the field of ammonia process flue gas desulfurization device system, can solve the problems of large amount of spray liquid, inability to realize continuous production of by-product ammonium sulfate, etc., so as to improve utilization rate, reduce temperature, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

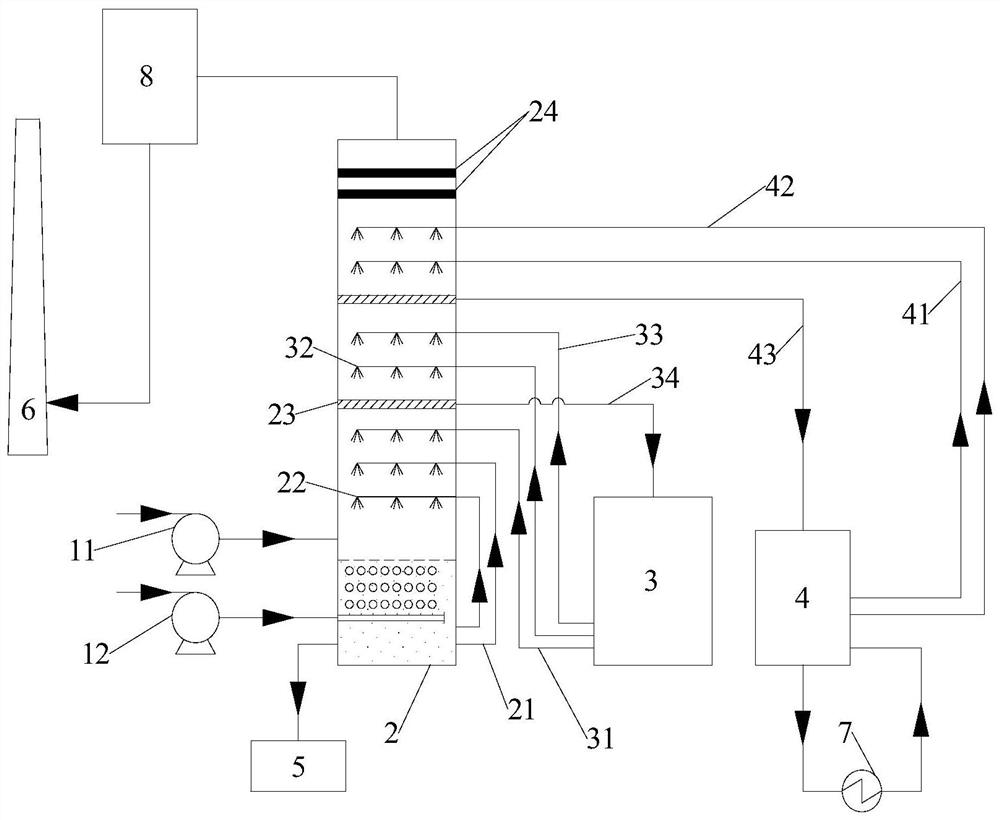

[0076] This embodiment provides a figure 1 The device system for ammonia-based flue gas desulfurization shown, the device system for ammonia-based flue gas desulfurization includes a desulfurization tower 2, a flue gas supply device 11, an oxidation gas supply device 12, a spray liquid storage tank 3, and a washing liquid storage tank 4. Absorption slurry post-processing device 5 and heat exchange device 7 .

[0077]The heat exchange device 7 is used to provide heat for the washing liquid in the washing liquid storage tank 4 .

[0078] The desulfurization tower 2 is arranged from bottom to top in the axial direction, including the slurry area, the first circulation area, the second circulation area, the third circulation area and the demisting area; it is arranged between the first circulation area and the second circulation area The gas separation tray 23 between the zones is connected to the spray liquid storage tank 3 through the spray slurry return pipeline 34; the gas se...

Embodiment 2

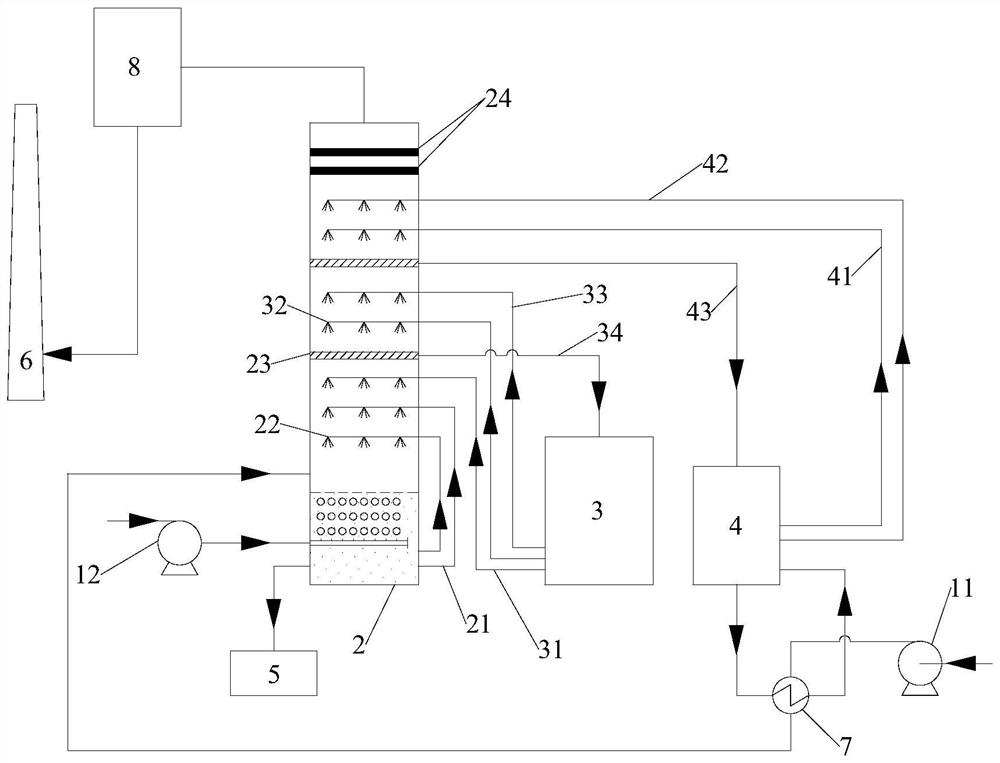

[0089] This embodiment provides a figure 2 The device system for ammonia-based flue gas desulfurization shown, the device system for ammonia-based flue gas desulfurization includes a desulfurization tower 2, a flue gas supply device 11, an oxidation gas supply device 12, a spray liquid storage tank 3, and a washing liquid storage tank 4. Absorption slurry post-processing device 5 and heat exchange device 7 .

[0090] The heat exchange device 7 is used to provide heat for the washing liquid in the washing liquid storage tank 4 ; the flue gas provided by the flue gas supply device 11 flows through the heat exchange device 7 , and then flows into the desulfurization tower 2 .

[0091] The desulfurization tower 2 is arranged from bottom to top in the axial direction, including the slurry area, the first circulation area, the second circulation area, the third circulation area and the demisting area; it is arranged between the first circulation area and the second circulation area...

Embodiment 3

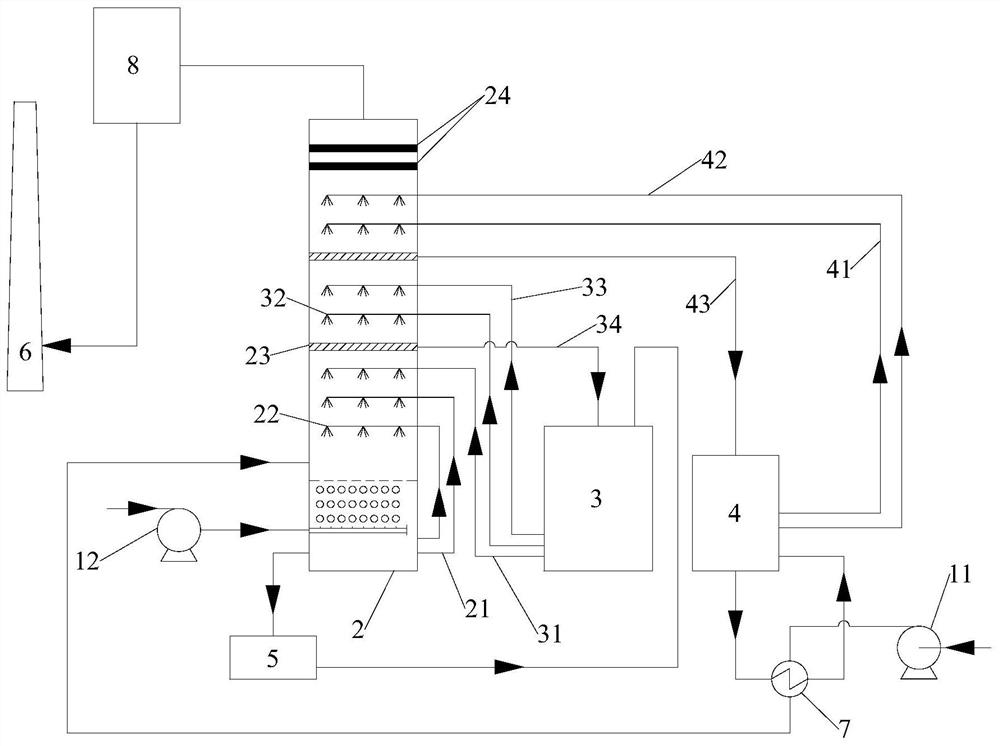

[0101] This embodiment provides a image 3 The device system for ammonia-based flue gas desulfurization shown, the device system for ammonia-based flue gas desulfurization includes a desulfurization tower 2, a flue gas supply device 11, an oxidation gas supply device 12, a spray liquid storage tank 3, and a washing liquid storage tank 4. Absorption slurry post-processing device 5 and heat exchange device 7 .

[0102] The heat exchange device 7 is used to provide heat for the washing liquid in the washing liquid storage tank 4 ; the flue gas provided by the flue gas supply device 11 flows through the heat exchange device 7 , and then flows into the desulfurization tower 2 .

[0103] The desulfurization tower 2 is arranged from bottom to top in the axial direction, including the slurry area, the first circulation area, the second circulation area, the third circulation area and the demisting area; it is arranged between the first circulation area and the second circulation area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com