Supported silver-manganese catalyst as well as preparation method and application thereof

A technology of manganese catalyst and supported silver, applied in the field of supported silver-manganese catalyst and its preparation, can solve problems such as pollution and ozone pollution, achieve the effect of large specific surface area and solve the problem of ozone pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a supported silver-manganese catalyst, which is prepared by the following method:

[0057] (1) Preparation of porous cube-shaped α-Mn 2 o 3 :

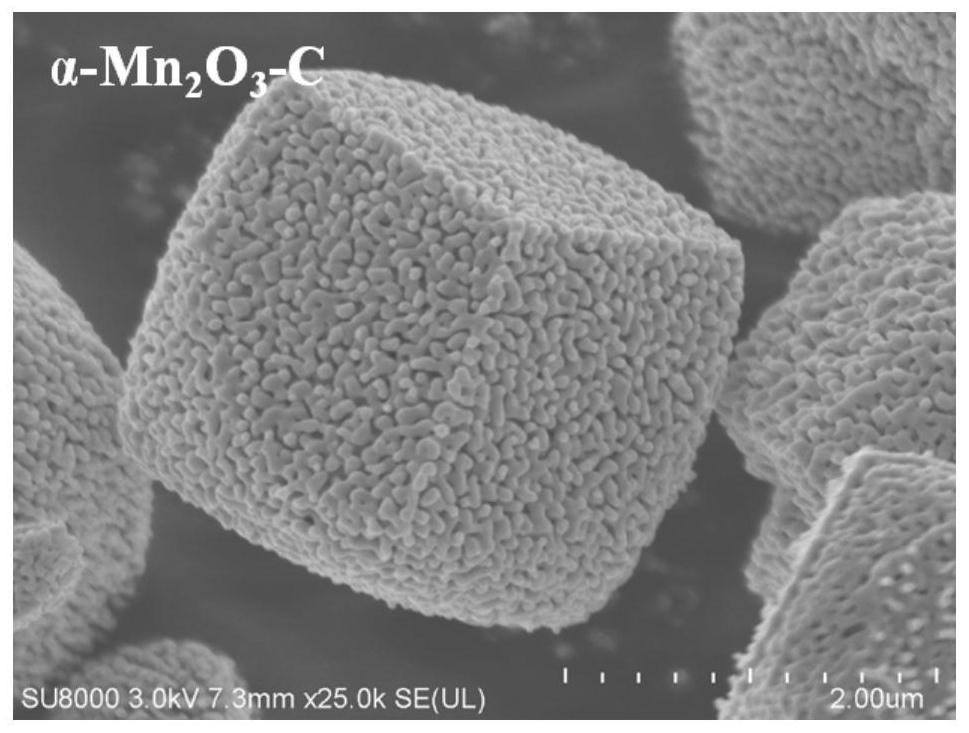

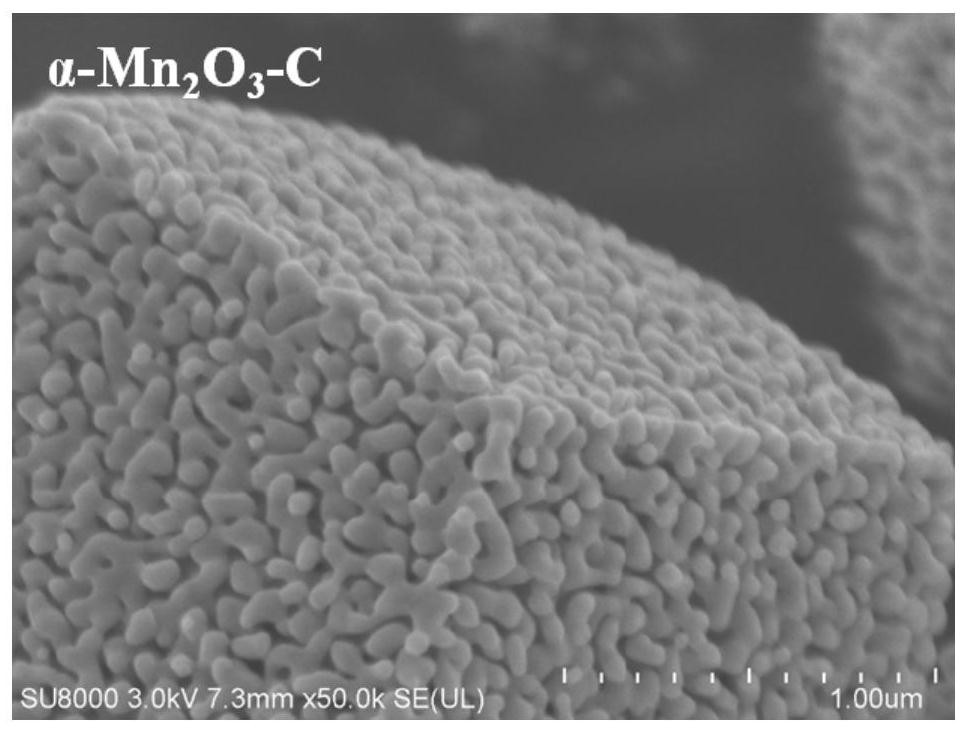

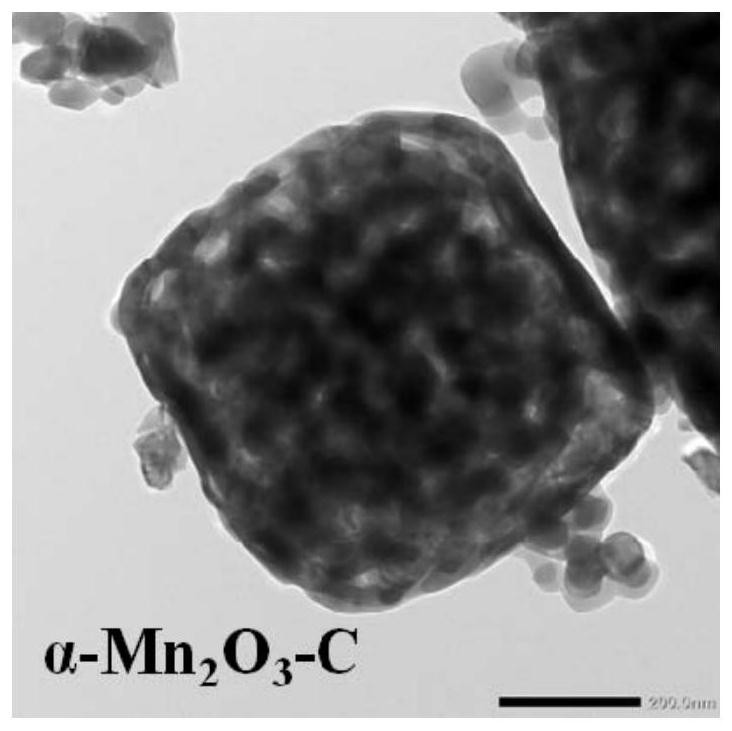

[0058] Dissolve 0.79g of potassium permanganate powder in 90mL of deionized water to form potassium permanganate solution, stir well, then add 0.99g of glucose powder into the above solution, stir for 30min until the solution is evenly mixed, then add the above solution into the reaction kettle Seal it and place it in an oven at 150°C for 10 hours. After the reaction is complete, the hydrothermal kettle is cooled to room temperature, and the obtained precipitate is suction-filtered, washed until neutral, and dried at 100°C for 20 hours to obtain cubic MnCO. 3 powder, and then the obtained MnCO 3 After the powder was calcined at 600 °C for 3 h, the microscopic morphology of α-Mn with porous cubes was obtained. 2 o 3 powder, the porous cube-type α-Mn 2 o 3 The SEM image and HRTEM image of the carrie...

Embodiment 2

[0062] This embodiment provides a supported silver-manganese catalyst, which is prepared by the following method:

[0063] (1) Preparation of porous cube-shaped α-Mn 2 o 3 :

[0064] Dissolve 0.88g of potassium permanganate powder in 90mL of deionized water to form a potassium permanganate solution, stir well, then add 1.2g of polyvinylpyrrolidone (PVP) powder into the above solution, stir for 25min until the solution is evenly mixed, and mix the above solution Put it into the reaction kettle and seal it, and put it in an oven at 160°C for 11 hours. After the reaction is completed, the hydrothermal kettle is cooled to room temperature, and the obtained precipitate is suction-filtered, washed until neutral, and dried at 120°C for 18 hours to obtain a cube with a microscopic shape. MnCO 3 powder, and then the obtained MnCO 3 After the powder was calcined at 800°C for 4 hours, the microscopic morphology of α-Mn with porous cubes was obtained. 2 o 3 powder;

[0065] (2) Pre...

Embodiment 3

[0068] The only difference between this example and example 1 is that the Ag load is adjusted to 2%, and other conditions and parameters are exactly the same as those of example 1, which are recorded as 2%Ag-α-Mn 2 o 3 -C silver manganese catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com