T23 water-cooling wall field repair method based on surfacing technology

A repair method and water-cooled wall technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult tube replacement welding, difficult operation, slow progress, etc., to avoid micro-cracks in weld bead, avoid arc welding Pit cracks, maintenance time reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

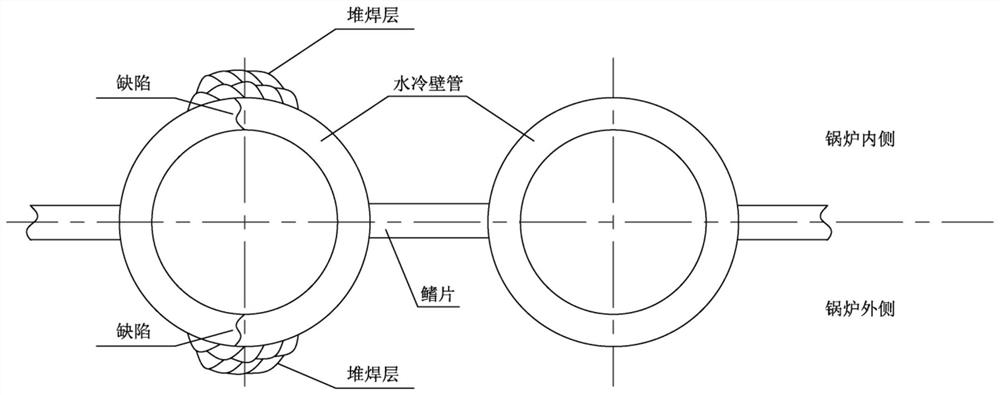

[0016] An on-site repair method for T23 water wall based on surfacing technology: using manual GTAW surfacing method to surfacing welding wire on the surface of the damaged pipe. There are 3 layers, so that the thickness of the surfacing layer is basically equal to the thickness of the water-cooled wall pipe. The operation schematic diagram is attached figure 1 As shown, the surfacing welding operation process is:

[0017] The tungsten electrode extension length is 5mm, the arc length control range is 2.5mm, the current is 120A, the welding speed is 70mm / min, the voltage is 15V, the shielding gas flow rate is 15L / min, the interlayer temperature is controlled within 150°C, the arc extinguishing time of manual welding is 5s, and the welding The heat input value is 5.6kJ / cm.

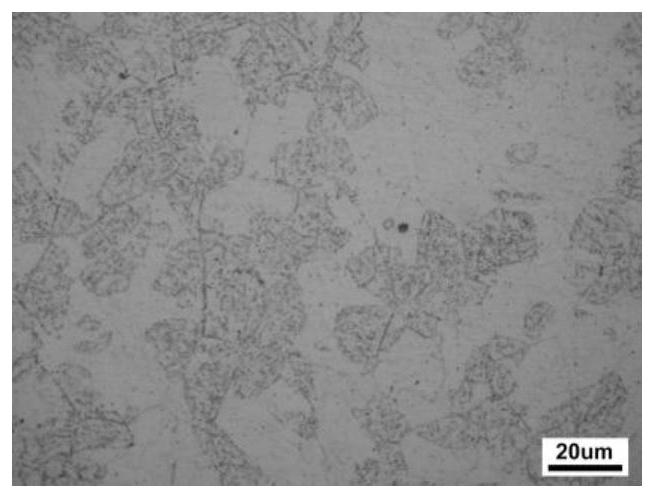

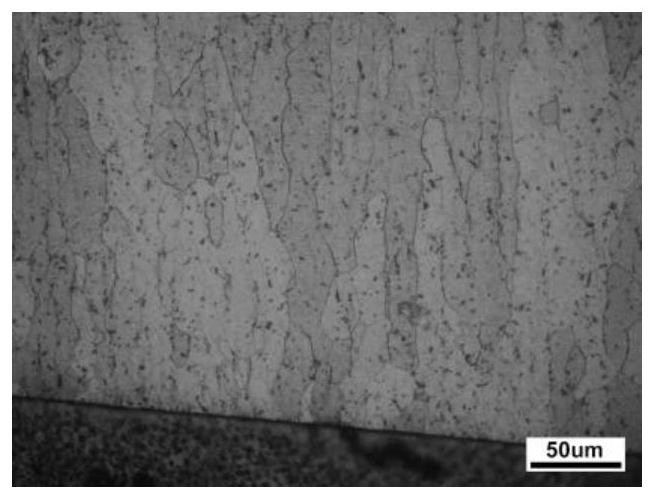

[0018] The effect after surfacing welding is as attached Figures 3 to 4 As shown, observe the structure of each area of the surfacing joint under a metallographic microscope, figure 2 Among them, the...

Embodiment 2

[0028] Increase the thickness of the surfacing layer until the surfacing layer is 5 layers, and the rest of the process operations are the same as in embodiment 1. After the surfacing is completed, according to the standard GB / T 31310-2014 "Metal Material Residual Stress Measurement Drilling Strain Method", the small hole release method (blind hole method) is used to measure the residual stress of the newly added nickel-based surfacing layer, as shown in the table 3 shows:

[0029] table 3

[0030] Overlay Residual stress, MPa layer 4 -268.0 layer 5 -271.0

[0031] It can be seen that when the thickness of the surfacing layer basically reaches the thickness of the water-cooled wall pipe (three-layer surfacing layer in this application), the contribution to the compressive stress of the water-cooled wall pipe is also very limited if the thickness of the surfacing layer is continued to increase. Therefore, the three-layer surfacing layer in this sch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com