A method for eliminating air holes in laser welding of Al-Li alloy T-joints

A laser welding, aluminum-lithium alloy technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as easy occurrence of pores, and achieve the effect of eliminating pores, promoting bubble escape, and reducing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] Example 1: The steps of static dual beam laser welding include:

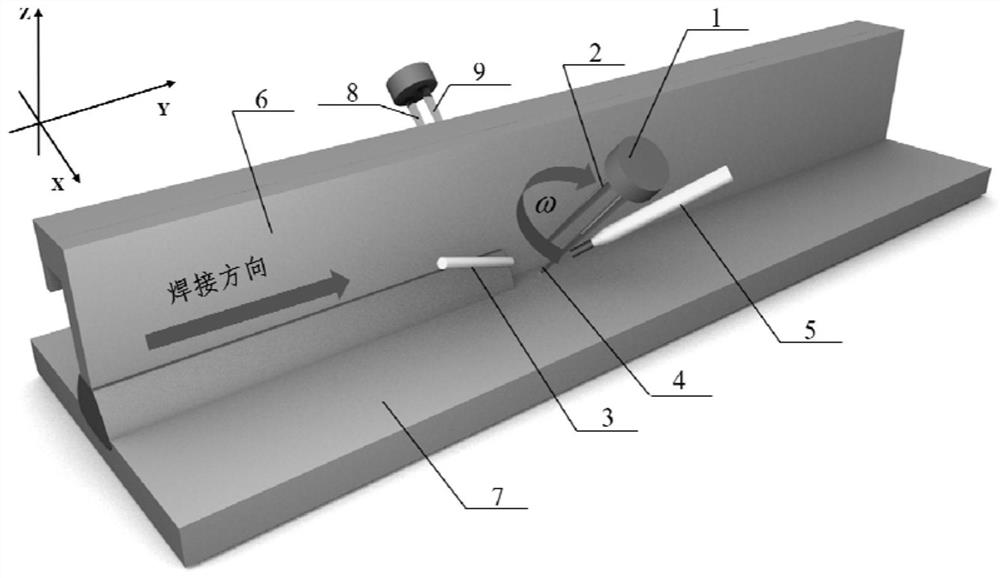

[0042] Step 1: After the aluminum-lithium alloy workpiece to be welded is subjected to mechanical grinding, anhydrous ethanol cleaning and drying in sequence, the surface of the workpiece to be welded is smooth and free of oil stains. The workpiece to be welded whose surface oxide film has been removed is fixed on the fixture, wherein the rib plate 6 is in a vertical state and is located above the bottom plate 7 in a horizontal state, and the two form an inverted "T" type structure, such as figure 1 shown.

[0043] Step 2: Apply dual laser beams on the left and right sides of the T-joint area to be welded respectively. The selected laser is CO. 2 Gas laser, in which the laser welding head is on the XZ plane, the included angle with the positive direction of the Z axis is 45°, the power of laser beam 1 and laser beam 2 are both 2000W, the beam defocus amount is 2mm, and the laser spot diameter is 0.3mm ....

example 2

[0047] The specific operation of this example is as follows:

[0048] Step 1: After the aluminum-lithium alloy workpiece to be welded is subjected to mechanical grinding, anhydrous ethanol cleaning and drying in sequence, the surface of the workpiece to be welded is smooth and free of oil stains. The workpiece to be welded whose surface oxide film has been removed is fixed on the fixture, wherein the rib plate 6 is in a vertical state and is located above the bottom plate 7 in a horizontal state, and the two form an inverted "T" type structure, such as figure 1 shown.

[0049] Step 2: Apply dual laser beams on the left and right sides of the T-joint area to be welded respectively. The selected laser is CO. 2 Gas laser, in which the laser welding head is on the XZ plane, the included angle with the positive direction of the Z axis is 45°, the power of laser beam 1 and laser beam 2 are both 2000W, the beam defocus amount is 2mm, and the laser spot diameter is 0.3mm .

[0050]...

example 3

[0053] The specific operation of this example is as follows:

[0054] Step 1: After the aluminum-lithium alloy workpiece to be welded is subjected to mechanical grinding, anhydrous ethanol cleaning and drying in sequence, the surface of the workpiece to be welded is smooth and free of oil stains. The workpiece to be welded whose surface oxide film has been removed is fixed on the fixture, wherein the rib plate 6 is in a vertical state and is located above the bottom plate 7 in a horizontal state, and the two form an inverted "T" type structure, such as figure 1 shown.

[0055] Step 2: Apply dual laser beams on the left and right sides of the T-joint area to be welded respectively. The selected laser is CO. 2 Gas laser, in which the laser welding head is on the XZ plane, the included angle with the positive direction of the Z axis is 45°, the power of laser beam 1 and laser beam 2 are both 2000W, the beam defocus amount is 2mm, and the laser spot diameter is 0.3mm .

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com