Lithium battery pole piece cutting auxiliary device

A technology for auxiliary devices and lithium batteries, applied in auxiliary devices, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient discharge of dust and debris, centralized processing, unqualified, easy-to-shake pole pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

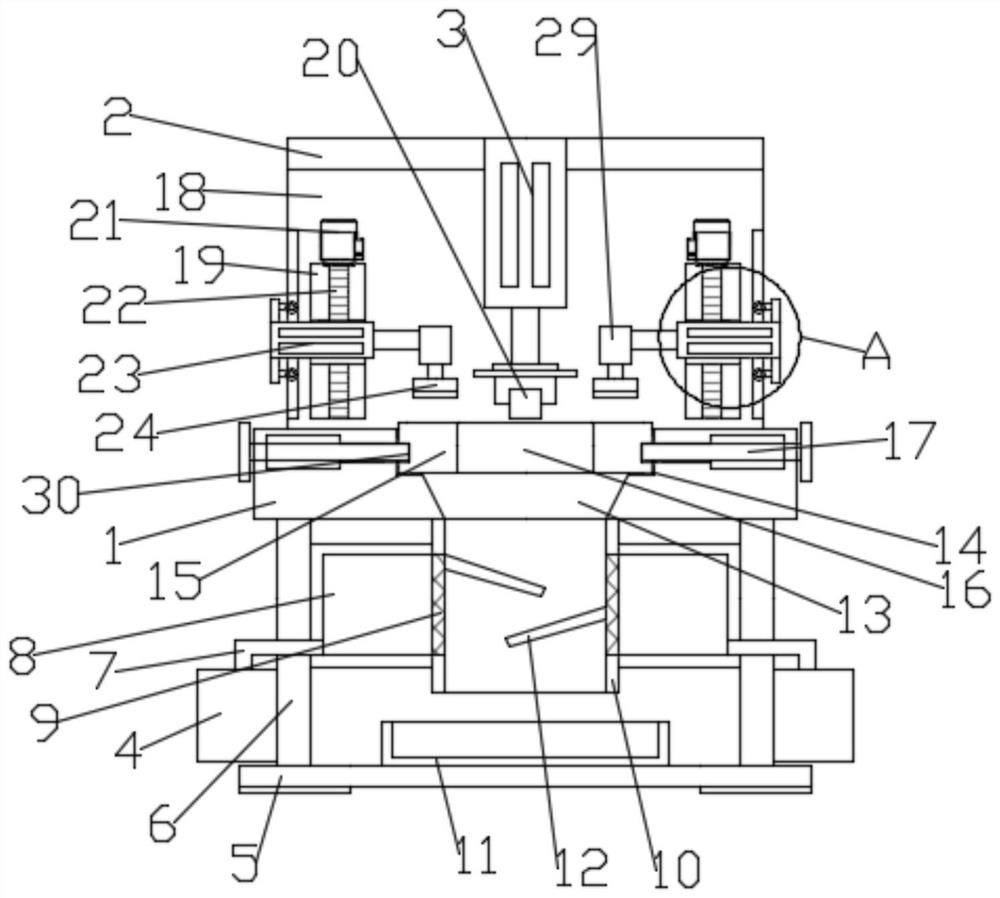

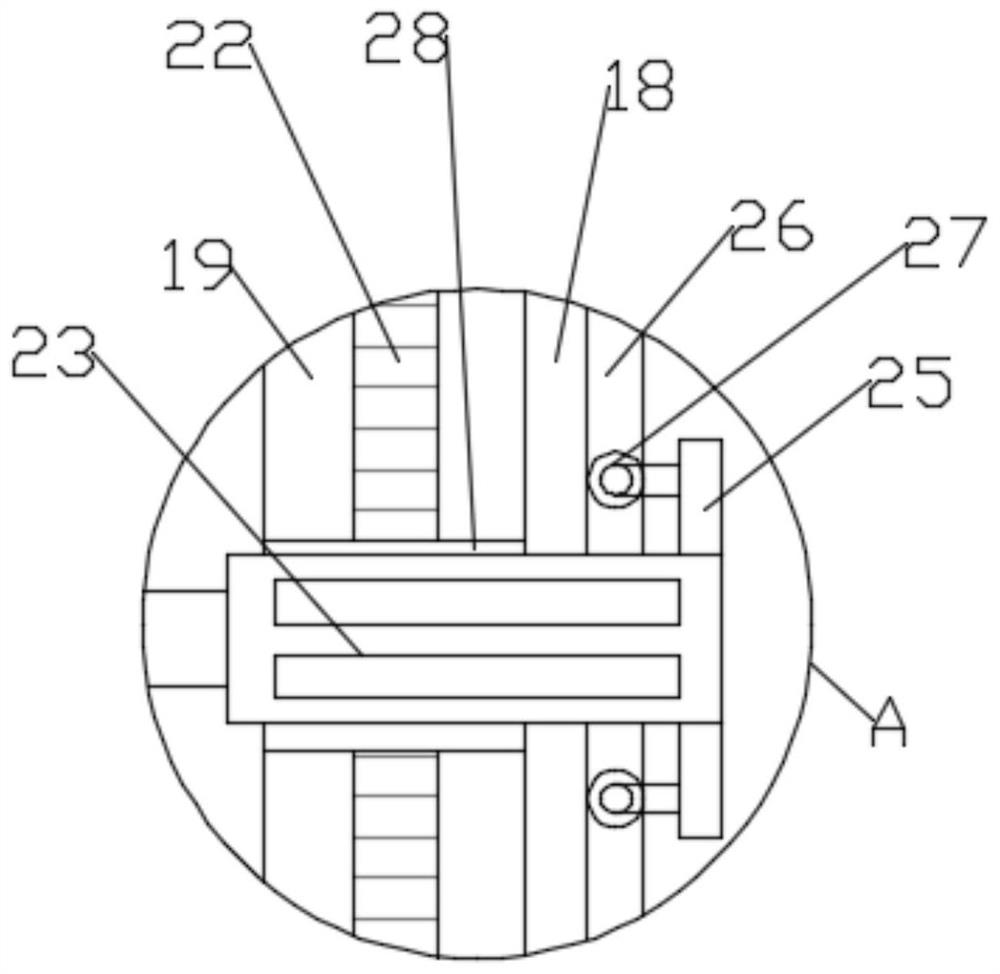

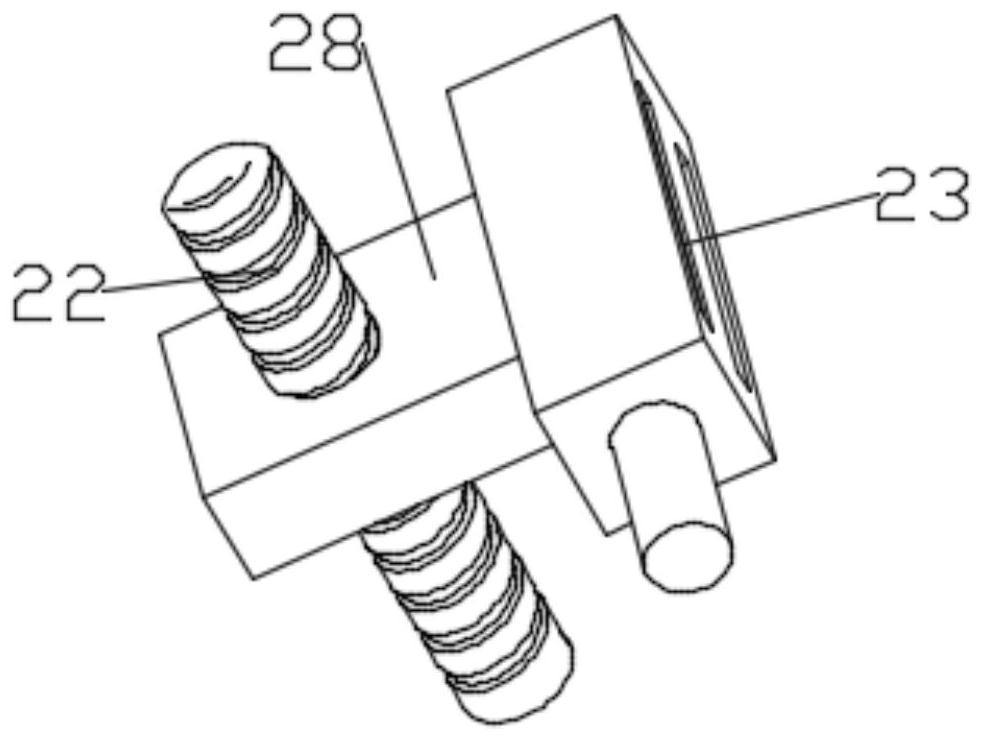

[0023] like figure 1 As shown, in one embodiment provided by the present invention, an auxiliary device for cutting lithium battery pole pieces includes a support platform 1, and a feeding channel 13 is opened in the middle of the support platform 1, and the middle part of the support platform 1 has a The surface is provided with a placement groove 14 corresponding to the discharge channel 13, and a cutting platform 15 is detachably installed in the placement groove 14, and a cutting platform 15 corresponding to the discharge passage 13 is provided on the cutting platform 15. The cutting channel 13, wherein the cutting platform 15 placed in the placement groove 14 is fixedly connected by mounting bolts 17, and both sides of the cutting platform 15 are provided with mounting screw grooves compatible with the mounting bolts 17 30. Tighten the installation bolt 17 until the end of the installation bolt 17 is screwed into the corresponding installation screw groove 30, so as to ac...

Embodiment 2

[0026] like figure 1 As shown, in one embodiment provided by the present invention, an auxiliary device for cutting lithium battery pole pieces includes a support platform 1, and a feeding channel 13 is opened in the middle of the support platform 1, and the middle part of the support platform 1 has a The surface is provided with a placement groove 14 corresponding to the discharge channel 13, and a cutting platform 15 is detachably installed in the placement groove 14, and a cutting platform 15 corresponding to the discharge passage 13 is provided on the cutting platform 15. The cutting channel 13, wherein the cutting platform 15 placed in the placement groove 14 is fixedly connected by mounting bolts 17, and both sides of the cutting platform 15 are provided with mounting screw grooves compatible with the mounting bolts 17 30. Tighten the installation bolt 17 until the end of the installation bolt 17 is screwed into the corresponding installation screw groove 30, so as to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com