Rapeseed oil squeezing device for edible oil processing and squeezing method

A technology of rapeseed oil and edible oil, which is applied in the direction of presses, manufacturing tools, fat oil/fat production, etc., can solve the problems of difficulty in controlling the extrusion force and inconvenience, and achieve the effect of improving pressing efficiency and quick oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

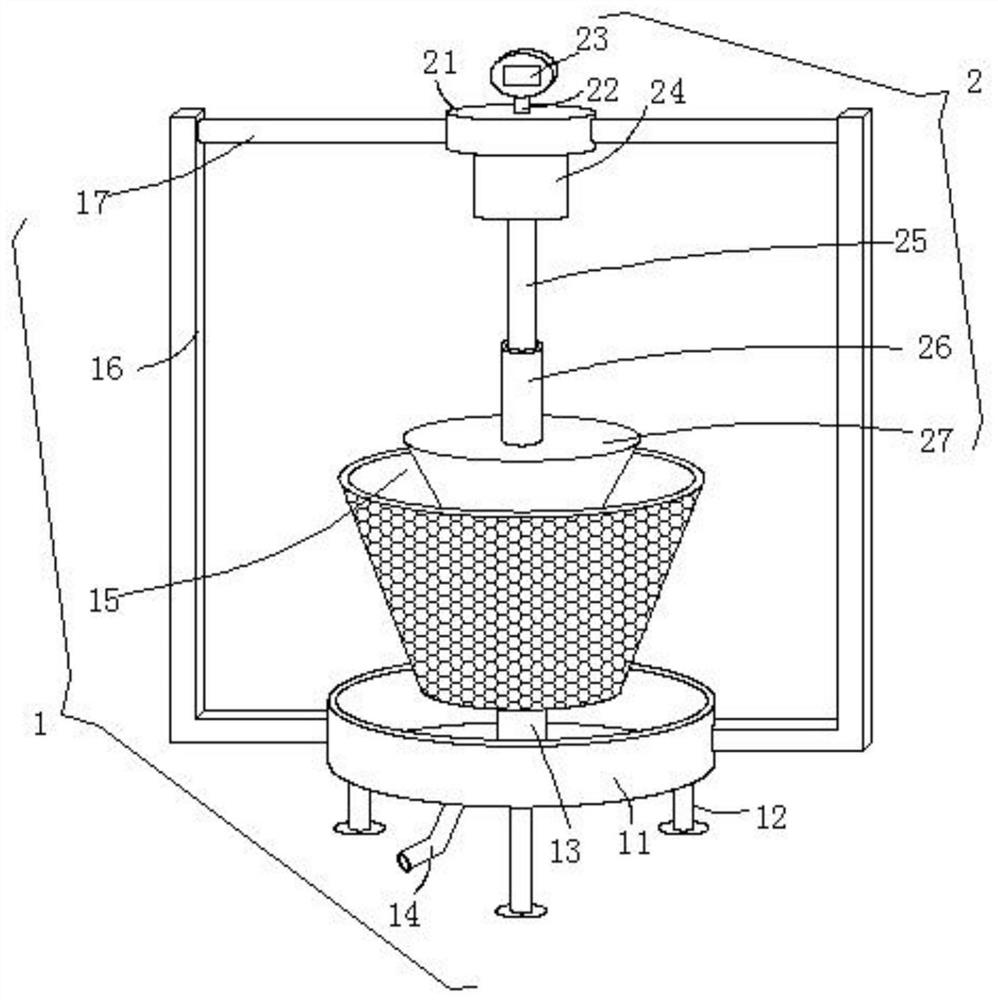

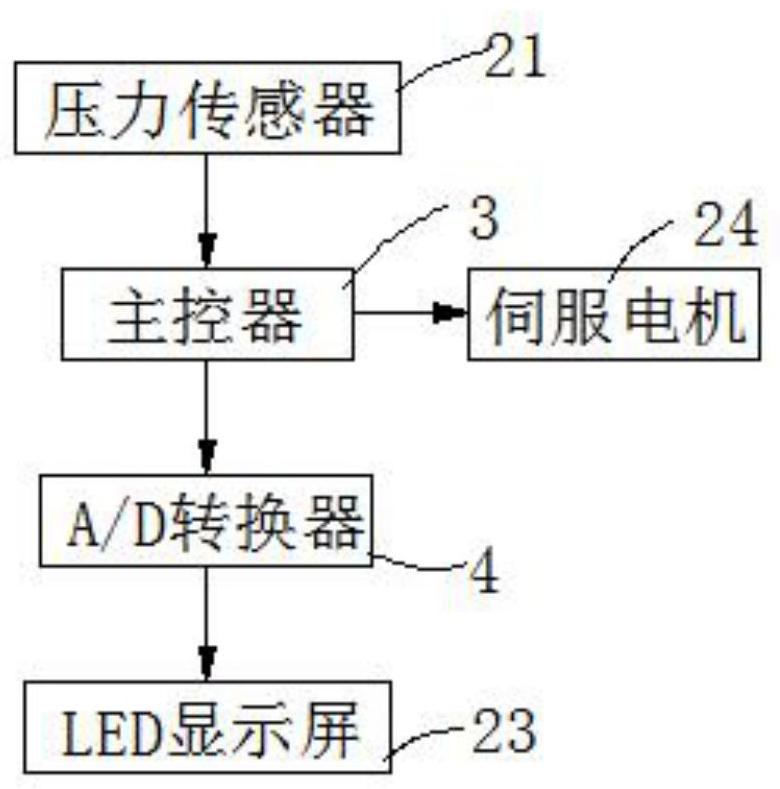

[0025] see Figure 1-3 , this embodiment provides a pressing method of a rapeseed oil pressing device for edible oil processing, including a supporting mechanism 1 and a squeezing mechanism 2, and the supporting mechanism 1 includes a rapeseed oil collecting pan 11, a pressing matching cylinder 15 and two L Type bracket 16, two L-shaped brackets 16 are left and right symmetrical, and are respectively fixedly welded on the outer wall both sides of rapeseed oil collection tray 11, two L-shaped brackets 16 opposite side wall tops all rotate horizontally and are provided with a rotating rod 17, and the pressing mechanism 2. It includes a pressure sensor 21, a servo motor 24, a threaded rod 25, a threaded sleeve 26 and a press counterweight 27. The relatively close ends of the two rotating rods 17 are fixedly connected to the left and right sides of the outer wall of the pressure sensor 21 respectively. The weight 27 is matched with the inner cavity of the press matching cylinder 1...

Embodiment 2

[0034] see Figure 1-3 , further improvements have been made on the basis of Example 1:

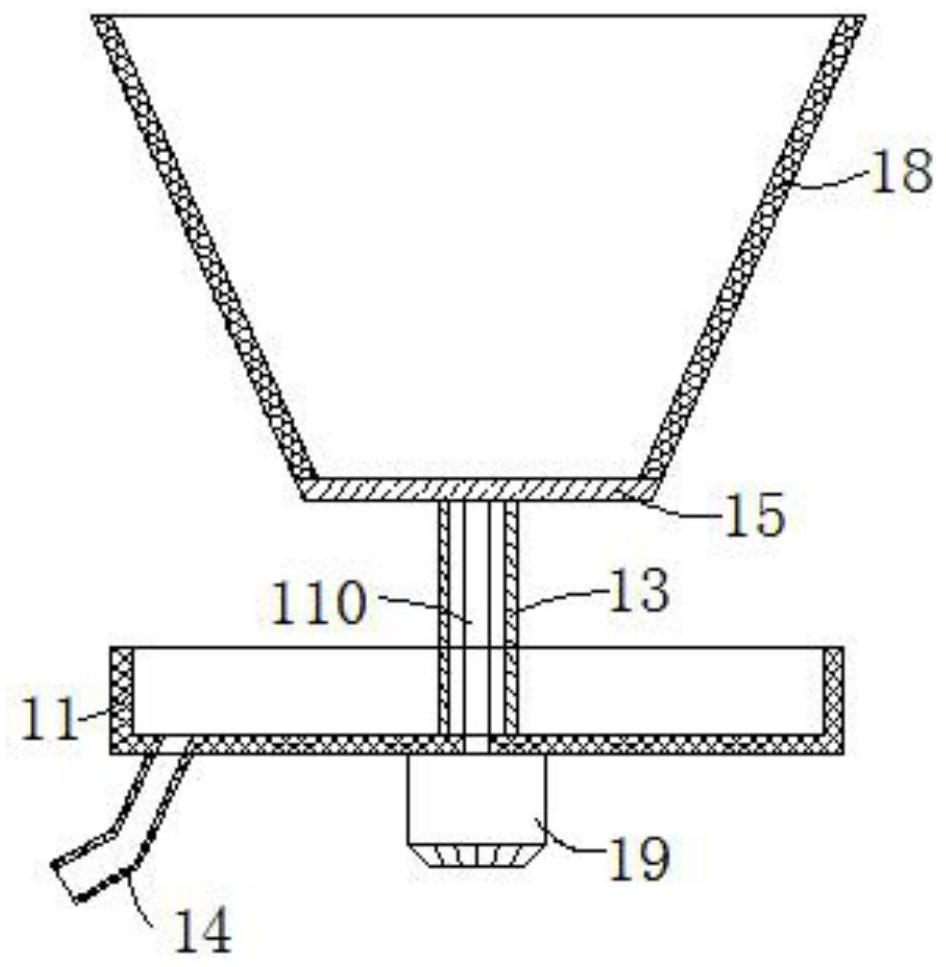

[0035] The center position of the bottom end surface of the rapeseed oil collecting tray 11 is fixedly provided with a geared motor 19, and the geared motor 19 runs through the bottom end surface of the rapeseed oil collecting tray 11 through the rotation of the power shaft, and is connected with a transmission rod 110, the top of the transmission rod 110 is connected to the pressing machine. The center position of the bottom end surface of the matching cylinder 15 is fixedly inserted, and the center position of the inner cavity bottom end surface of the rapeseed oil collection plate 11 is vertically provided with a guide cylinder 13, which is sleeved on the outside of the transmission rod 110, and the inside of the guide cylinder 13 The radial distance between the radial side wall of the cavity and the outer wall of the transmission rod 110 is 10 mm. The top surface of the guide cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com