Ceramic slurry and preparation method and application thereof

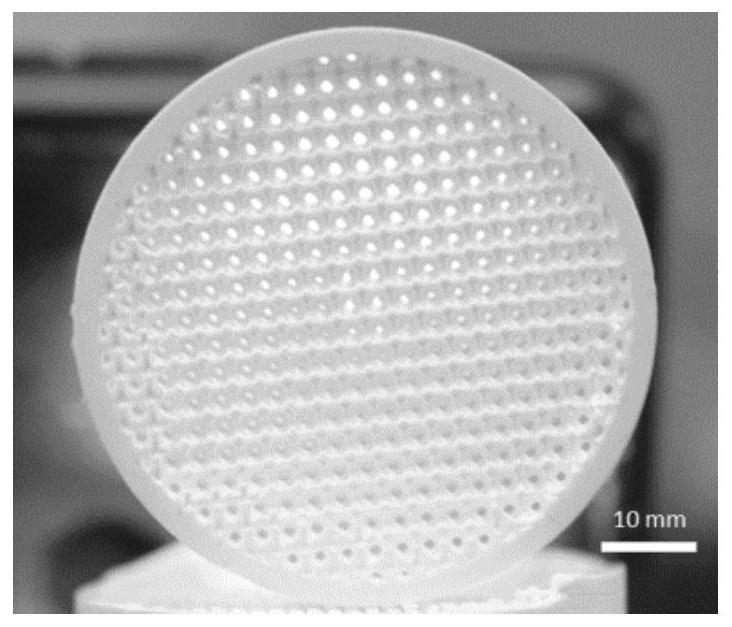

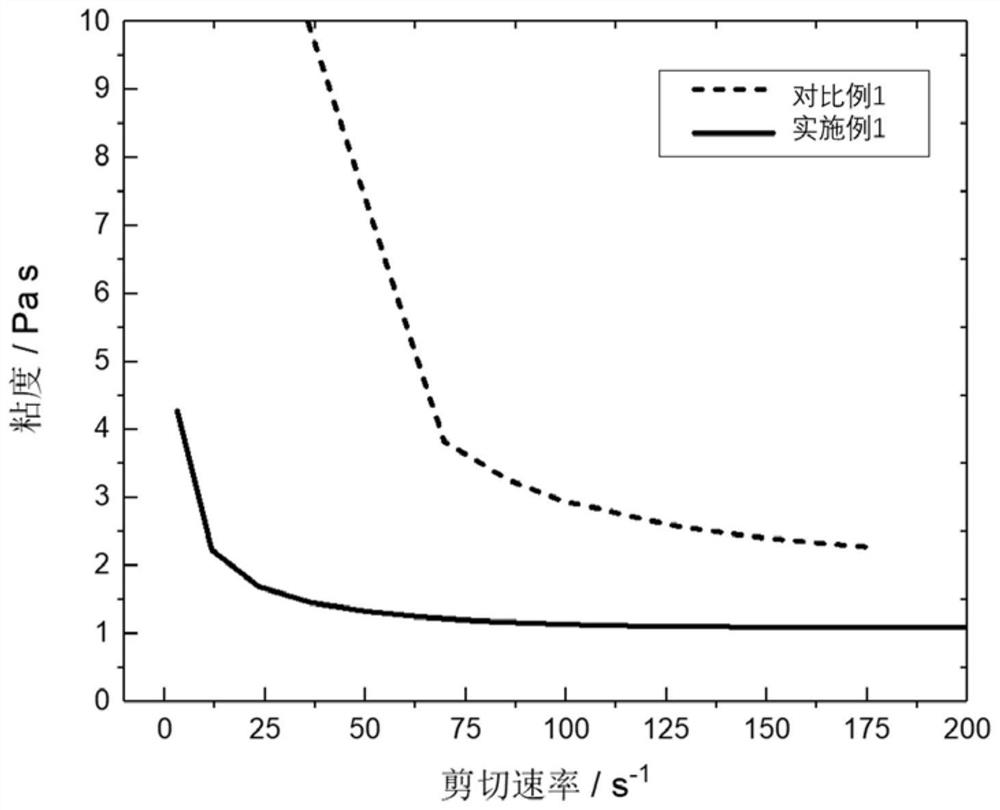

A technology of ceramic slurry and ceramic powder, applied in the field of 3D printing, can solve the problems of difficult removal of slurry, difficult self-leveling of slurry, unfavorable cleaning, etc., and achieves the effect of high compliance rate, less bubbles and less hole blocking phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a preparation method of zirconia ceramic slurry, which preparation method comprises the following steps:

[0044] S1: Weigh 0.5 g of polymer hyperdispersant and add it into 100 ml of absolute ethanol, and magnetically stir until completely dissolved to obtain the first dispersant solution. Add 30 g of zirconia ceramic powder into the first dispersant solution, stir magnetically at 60° C. for 2 hours, dry and sieve to obtain modified zirconia ceramic powder.

[0045] S2: Take 30 g of modified zirconia ceramic powder, 0.1 g of phenylbis(2,4,6-trimethylbenzoyl) phosphine oxide, 7 g of acryloyl morpholine and 3 g of polyethylene glycol diacrylate and mix them. The zirconia ceramic slurry was obtained by ball milling in a planetary ball mill at room temperature for 0.5 hour.

[0046] S3: Weigh 0.1g of polymer hyperdispersant and dissolve it in 10ml of absolute ethanol at 60°C, stir magnetically to form a second dispersant solution, and mill the seco...

Embodiment 2

[0053] This embodiment provides a preparation method of zirconia ceramic slurry, which preparation method comprises the following steps:

[0054] S1: Weigh 13.5g of polymer hyperdispersant and add it into 300ml of absolute ethanol, and magnetically stir until completely dissolved to obtain the first dispersant solution. Add 270 g of zirconia ceramic powder into the first dispersant solution, stir magnetically for 5 hours at 60° C., dry and sieve to obtain modified zirconia ceramic powder.

[0055] S2: Take 270g of modified zirconia ceramic powder, 0.55g of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide, 40g of 1,6-hexanediol dimethacrylate and polyethylene 15 g of diol diacrylate was mixed, and ball milled in a planetary ball mill at room temperature for 2 hours to obtain a zirconia ceramic slurry.

[0056] S3: Weigh 2g of polymer hyperdispersant and dissolve it in 10ml of absolute ethanol (the volume is about 2% of the final volume of the slurry) at 60°C, stir magnetically...

Embodiment 3

[0062] This embodiment provides a preparation method of alumina ceramic slurry, the preparation method comprising the following steps:

[0063] S1: Weigh 1.8g of polymer hyperdispersant and add it into 200ml of absolute ethanol, and magnetically stir until completely dissolved to obtain the first dispersant solution. Add 60 g of alumina ceramic powder into the first dispersant solution, stir magnetically at 60° C. for 3 hours, dry and sieve to obtain modified alumina ceramic powder.

[0064] S2: Take 60g of modified alumina ceramic powder, 0.55g of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide, 5g of isobornyl acrylate and 5g of polyethylene glycol diacrylate and mix them. The alumina ceramic slurry was obtained by ball milling in a planetary ball mill at room temperature for 1 hour.

[0065] S3: Weigh 0.2g of polymer hyperdispersant and dissolve it in 10ml of absolute ethanol at 60°C, stir magnetically to form a second dispersant solution, and mill the second dispersant s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com