Cathode material and preparation method and application thereof

A positive electrode material, alumina technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems that affect the uniformity of active material distribution on the electrode sheet, low mechanical strength of nano hollow spheres, complex layered coating operation, etc. , to achieve the effect of improving electrochemical performance, facilitating infiltration and absorption, convenient operation and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

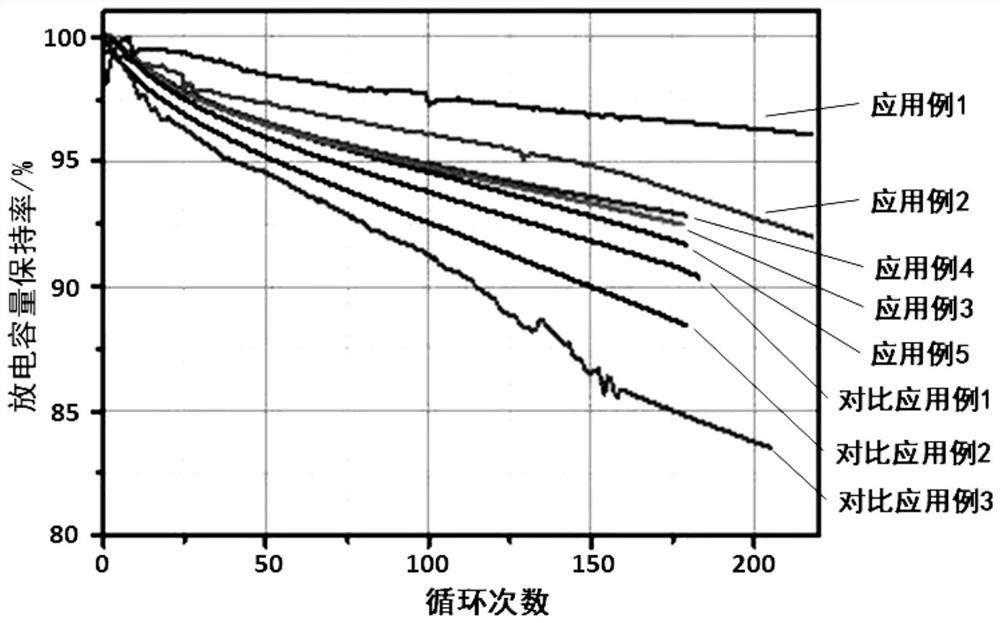

Examples

Embodiment 1

[0068] This embodiment provides a positive electrode material and a preparation method thereof, the preparation method comprising the following steps:

[0069] (1) preparing alumina, specifically comprising:

[0070] (a) mixing and stirring the template agent hexadecyltrimethylammonium bromide and the aluminum source solution with a mass ratio of 1:25 to obtain a precursor solution; the stirring speed is 550rpm, and the time is 3h; the aluminum The source solution is prepared by mixing elemental aluminum with a mass ratio of 1:7.5 and an acetic acid solution with a concentration of 3mol / L;

[0071] (b) hydrothermally treating the precursor solution obtained in step (a) at 150° C. for 3 h, filtering and washing to obtain a solid substance;

[0072] (c) drying and calcining the solid matter obtained in step (b) to obtain alumina; the drying temperature is 80°C for 9 hours; the roasting temperature is 800°C for 2 hours;

[0073] (2) Alumina-coated lithium iron phosphate, specif...

Embodiment 2

[0078] This embodiment provides a positive electrode material and a preparation method thereof, the preparation method comprising the following steps:

[0079] (1) preparing alumina, specifically comprising:

[0080] (a) mixing and stirring the template agent hexadecyltrimethylammonium bromide and the aluminum source solution with a mass ratio of 1:22.5 to obtain a precursor solution; the stirring speed is 325rpm, and the time is 4h; the aluminum The source solution is prepared by mixing elemental aluminum with a mass ratio of 1:6.25 and a citric acid solution with a concentration of 4mol / L;

[0081] (b) hydrothermally treating the precursor solution obtained in step (a) at 125° C. for 3.5 hours, and obtaining a solid substance after suction filtration and washing;

[0082] (c) drying and roasting the solid matter obtained in step (b) to obtain alumina; the drying temperature is 70°C for 10.5 hours; the roasting temperature is 775°C for 2.5 hours;

[0083] (2) Alumina-coated...

Embodiment 3

[0089] This embodiment provides a positive electrode material and a preparation method thereof, the preparation method comprising the following steps:

[0090] (1) preparing alumina, specifically comprising:

[0091] (a) mixing and stirring the template agent hexadecyltrimethylammonium bromide and the aluminum source solution with a mass ratio of 1:27.5 to obtain a precursor solution; the stirring speed is 775rpm, and the time is 2h; the aluminum The source solution is prepared by mixing elemental aluminum with a mass ratio of 1:8.75 and an acetic acid solution with a concentration of 2mol / L;

[0092] (b) hydrothermally treating the precursor solution obtained in step (a) at 175° C. for 2.5 hours, centrifuging and washing to obtain a solid substance;

[0093] (c) drying and roasting the solid matter obtained in step (b) to obtain alumina; the drying temperature is 90°C for 7.5 hours; the roasting temperature is 825°C for 1.5 hours;

[0094] (2) Alumina-coated lithium iron phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com