Soup food material processing method of air fryer

A processing method, air fryer technology, applied in steam cooking utensils, cooking utensils, household utensils, etc., can solve the single working environment, can not better realize the cooking of soup ingredients, can not meet the different cooking of soup ingredients Environmental needs and other issues to achieve the effect of reducing heat demand, avoiding steam consumption, improving nutrition and flavor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to explain the overall concept of the present application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

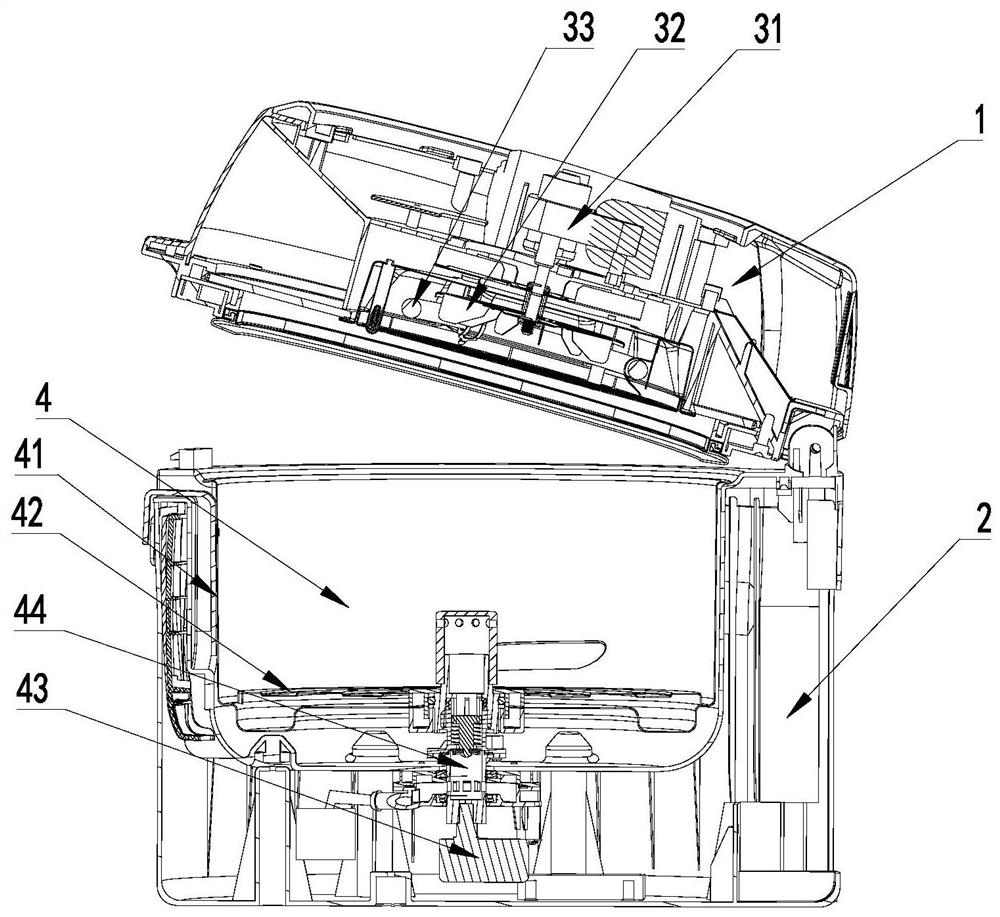

[0031] like figure 1As shown, it is an air fryer capable of realizing the processing method of soup ingredients in the present invention, including a machine base 2 and a machine head 1, the machine head 1 is hinged to the machine base 2, and the machine head 1 is connected to the The base 2 forms a working space 4 surrounded by a working space 4. Processing components are arranged in the working space 4. The processing components include a fryer 41 and a frying basket 42 arranged in the working space 4. The frying basket 42 is placed on the frying pan 42. In the pot 41, there is a gap between the frying basket 42 and the bottom wall of the frying pot 41 for air flow to better complete the processing. The soup ingredients for cooking and processing are preferably placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com