Fiber-reinforced rock plate and preparation method thereof

A technology of fiber reinforcement and slate, applied in the field of building materials, can solve the problems of limited mechanical performance improvement, long process, and high cost of slabs, and achieve high feasibility of technical implementation, improved bending strength and toughness, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

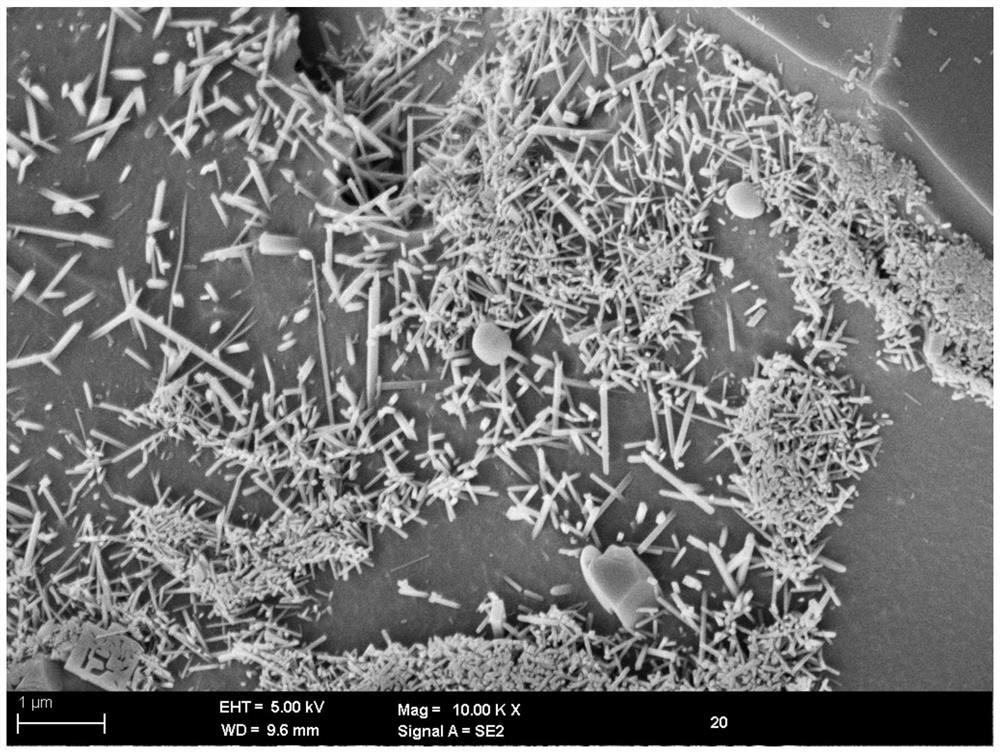

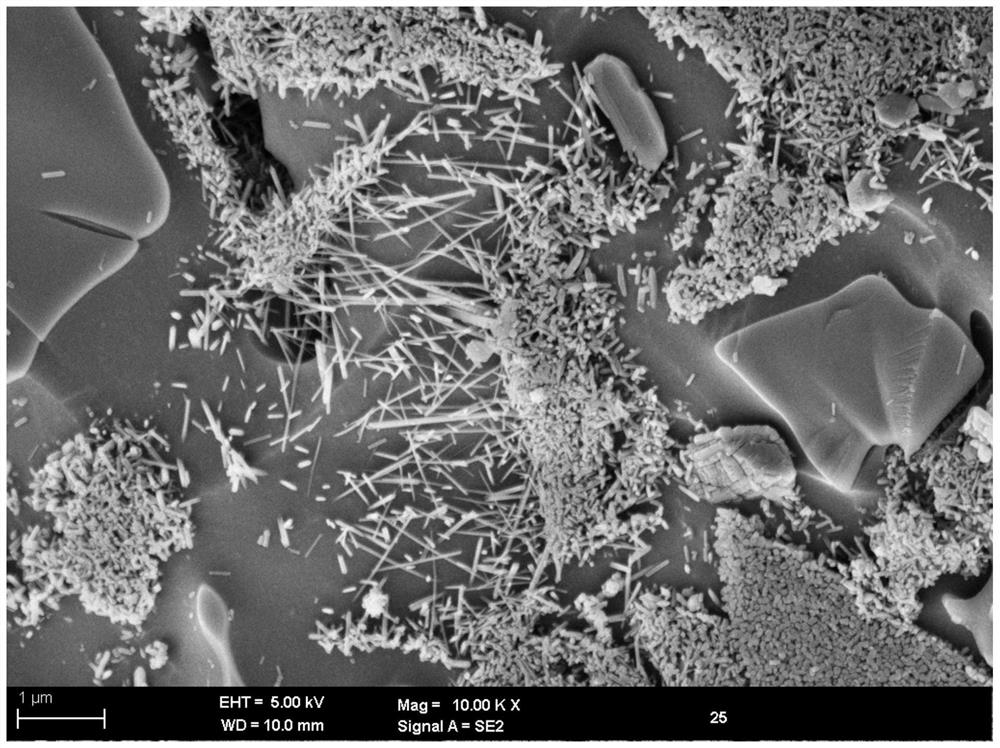

Image

Examples

Embodiment 1

[0031] A fiber-reinforced rock slab includes the following raw materials in parts by weight: 38 parts of kaolin, 17 parts of bauxite, 20 parts of feldspar, 2 parts of talc, 16 parts of quartz and 7 parts of polycrystalline alumina fiber; wherein, polycrystalline oxide The melting point temperature of the aluminum fiber is >1400°C, and the diameter is 0.1 μm. The preparation method of the rock plate is as follows:

[0032] S1: Mix polycrystalline alumina fiber, dispersant and water evenly, and ball mill and mix to prepare ceramic fiber dispersion; wherein, the dispersant is sodium tripolyphosphate, and the dosage is 0.5% of the total mass of the slate powder;

[0033] S2: Add kaolin, bauxite, feldspar, talc and quartz to the prepared ceramic fiber dispersion, and ball mill and mix for 12 hours to prepare a mixed slurry with a solid content of 55%;

[0034] S3: The mixed slurry is spray-dried and granulated to obtain a spherical particle powder with certain fluidity and sieved t...

Embodiment 2

[0039] A fiber-reinforced rock slab includes the following raw materials in parts by weight: 30 parts of kaolin, 29 parts of bauxite, 15 parts of feldspar, 25 parts of quartz and 1 part of polycrystalline alumina fiber; wherein, the melting point of polycrystalline alumina fiber The temperature is >1400°C and the diameter is 0.1 μm. The preparation method of the slab is as follows:

[0040] S1: Mix polycrystalline alumina fiber, dispersant and water evenly, and ball mill to prepare a ceramic fiber dispersion; wherein, the dispersant is sodium hexametaphosphate, and the dosage is 0.5% of the total mass of the slate powder;

[0041] S2: Add kaolin, bauxite, feldspar, talc and quartz to the prepared ceramic fiber dispersion, and ball mill and mix for 12 hours to prepare a mixed slurry with a solid content of 50%;

[0042] S3: The mixed slurry is spray-dried and granulated to obtain a spherical particle powder with certain fluidity and sieved to obtain particles with a particle si...

Embodiment 3

[0046] A fiber-reinforced rock slab includes the following raw materials in parts by weight: 45 parts of kaolin, 10 parts of bauxite, 25 parts of feldspar, 2 parts of talc, 15 parts of quartz and 3 parts of polycrystalline alumina fiber; wherein, polycrystalline The melting point temperature of the aluminum fiber is >1400°C, and the diameter is 1 μm. The preparation method of the rock plate is as follows:

[0047] S1: Mix the polycrystalline alumina fiber, dispersant and water evenly, and mix them by ball milling to prepare a ceramic fiber dispersion; wherein, the dispersant is sodium polyacrylate, and the dosage is 0.5% of the total mass of the slate powder;

[0048] S2: Add kaolin, bauxite, feldspar, talc and quartz to the prepared ceramic fiber dispersion, ball mill and mix for 0.5h to prepare a mixed slurry with a solid content of 60%;

[0049]S3: The mixed slurry is spray-dried and granulated to obtain a spherical particle powder with certain fluidity and sieved to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com