Shape memory polymer structure capable of selectively responding and preparation method thereof

A memory polymer, an optional technology, applied in manufacturing, additive processing, etc., can solve the problems of limited processing methods and cumbersome procedures, and achieve the effect of broadening manufacturing methods, reducing manufacturing costs, and shortening manufacturing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the selectively responsive shape memory polymer structure of the present invention comprises the following steps:

[0032] using a 3D printing device to print a body structure with several cavities with a shape memory polymer;

[0033] Weigh a certain mass of nanoparticles and add them to silicone oil, water and other solvents for stirring to make a certain concentration of particle solution; fill the cavity of the body structure with nanoparticle solution, and use AB glue to seal after injection. The nanoparticle solution can generate heat under external excitation;

[0034] The bulk structure filled with nanoparticle solution is heated, and the bulk structure is deformed by external force; the deformed bulk structure is cooled and shaped, and the shaped bulk structure can be restored to the bulk structure before external force deformation under the action of external excitation.

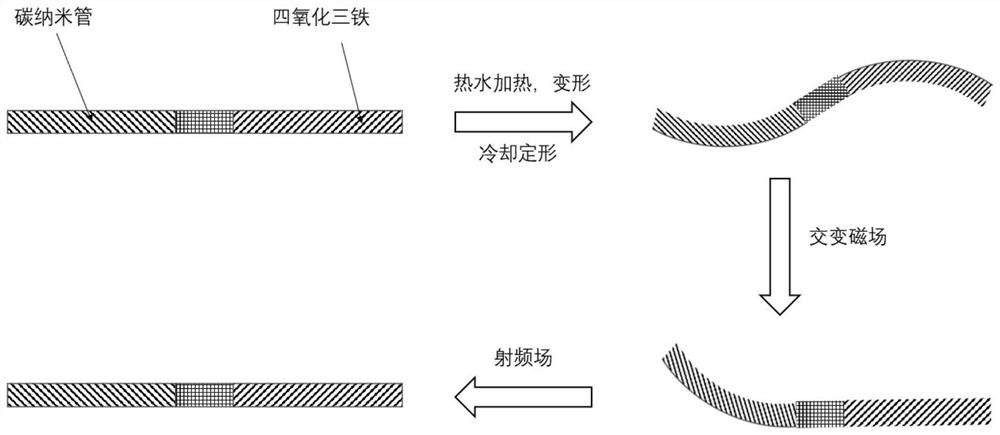

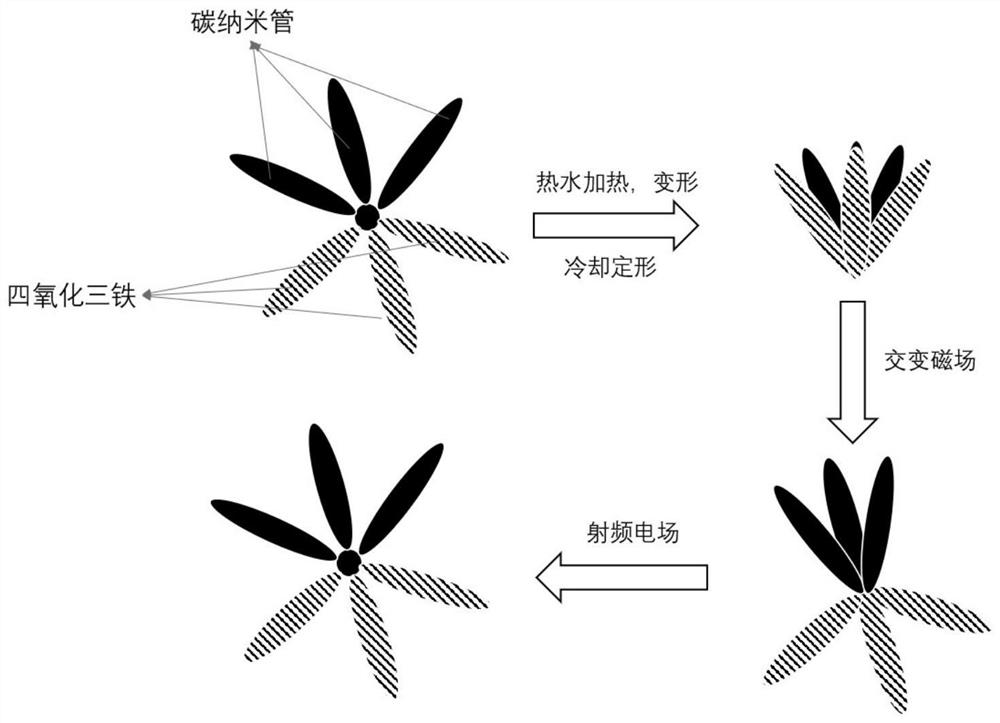

[0035] The nanoparticle solution added in the present inventi...

Embodiment 1

[0040] Use 80% epoxy soybean oil acrylate + 20% methacrylic acid to prepare a shape memory polymer, and use an LCD light-curing printer to print a rectangular groove with an outer cross-sectional size of 10×2.5mm 2 , the cross-sectional size of the groove is 8×2mm 2 , the body length is 50mm. Use absolute ethanol to clean the uncured resin inside and outside the sample, and use AB glue to seal one end of the groove after cleaning;

[0041] Nano-Fe with a mass fraction of 30% 3 o 4 Add simethicone oil and ultrasonically disperse for 20 minutes, inject the mixed particle liquid into the sample from the unsealed end of the channel, and seal it with AB glue after the injection is completed. Nano Fe 3 o4 Under the action of an alternating magnetic field, a relaxation phenomenon occurs to generate heat, which can endow the sample with additional magnetic responsiveness.

[0042] Use hot water to heat the body, apply an external force to bend it, put it in cold water for 5 minut...

Embodiment 2

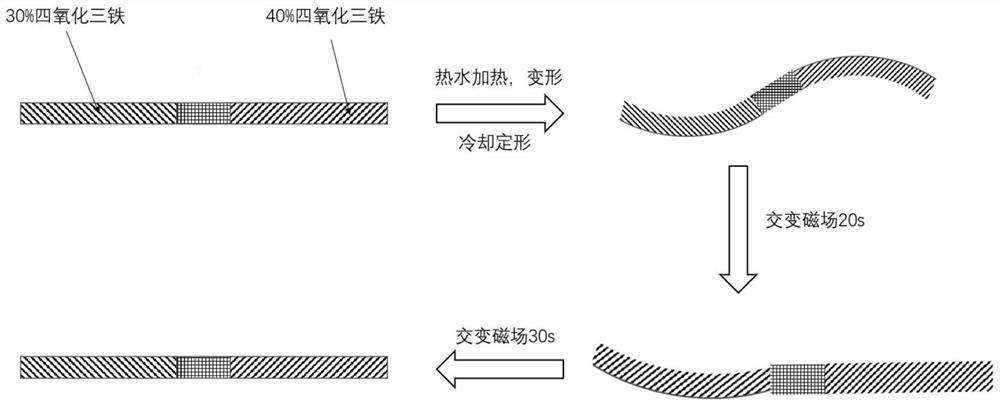

[0043] Example 2, such as figure 1 Shown:

[0044] Use 80% epoxy soybean oil acrylate + 20% methacrylic acid to prepare shape memory polymer, and use LCD light curing printer to print a rectangular groove with a size of 10×2.5×50mm 3 , the rectangular piece has two through slots along the length direction, and the cross-sectional size of the through slots is 20×2mm 2 . Use absolute ethanol to clean the uncured resin inside and outside the sample, and use AB glue to seal one end of the groove after cleaning;

[0045] Configure Fe with mass fractions of 30% and 40% respectively 3 o 4 and simethicone dispersion, inject them into the two channels respectively, and seal them with AB glue after the injection is completed. Nano Fe 3 o 4 The speed and size of the heat generated under the action of the alternating magnetic field are related to the content of the particles. The more the particle content, the faster the heat generation and the higher the temperature.

[0046] Use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com