Rotary embedded electrostatic spinning device and spinning method

A technology of electrospinning and spinning solution, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc. It can solve the problems of few fiber diameter series, unclear diameter distribution levels, and uncontrollable distribution, etc., to achieve Less solvent volatilization, stable and continuous batch production, and the effect of improving spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

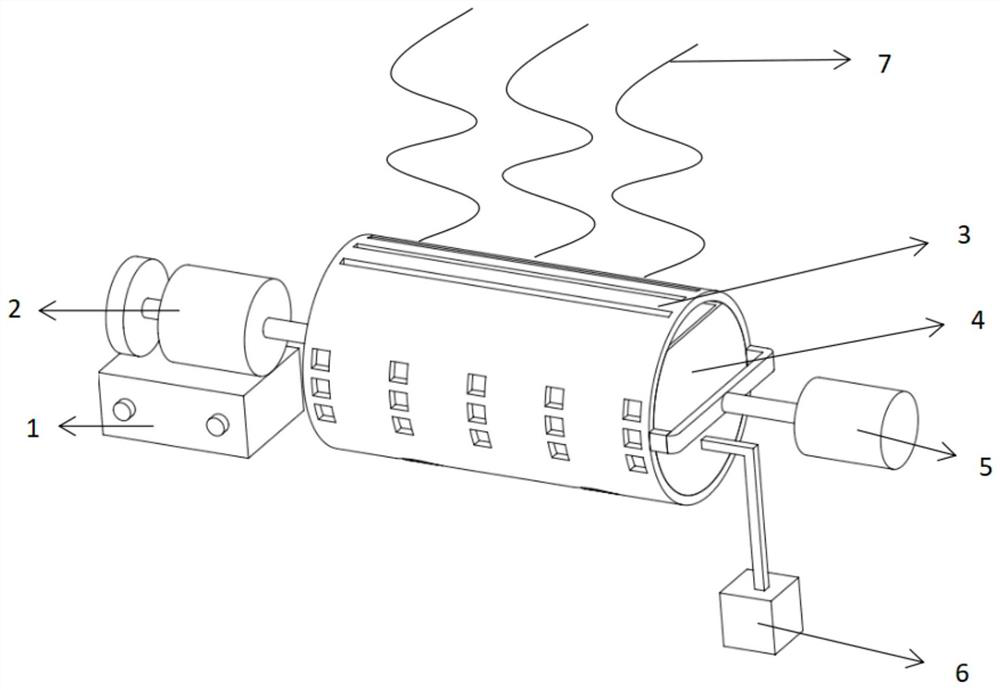

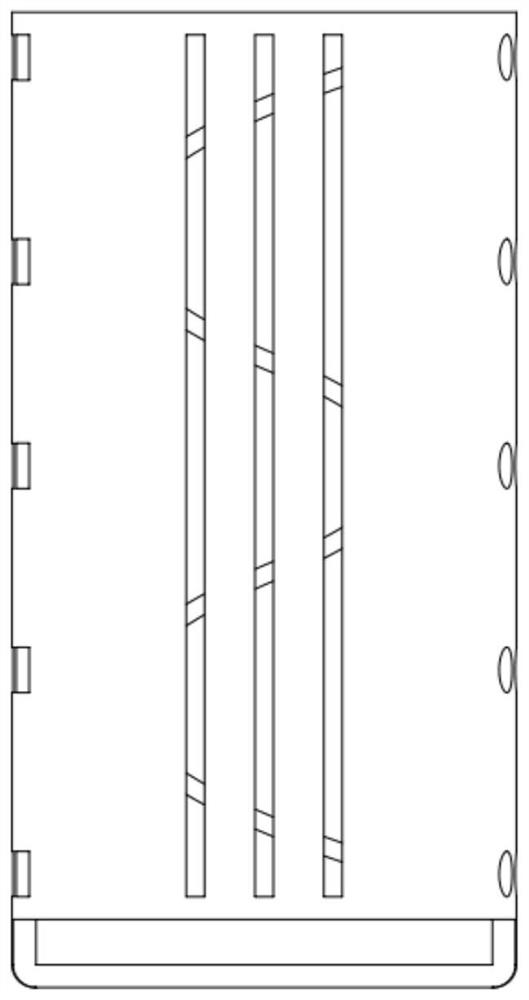

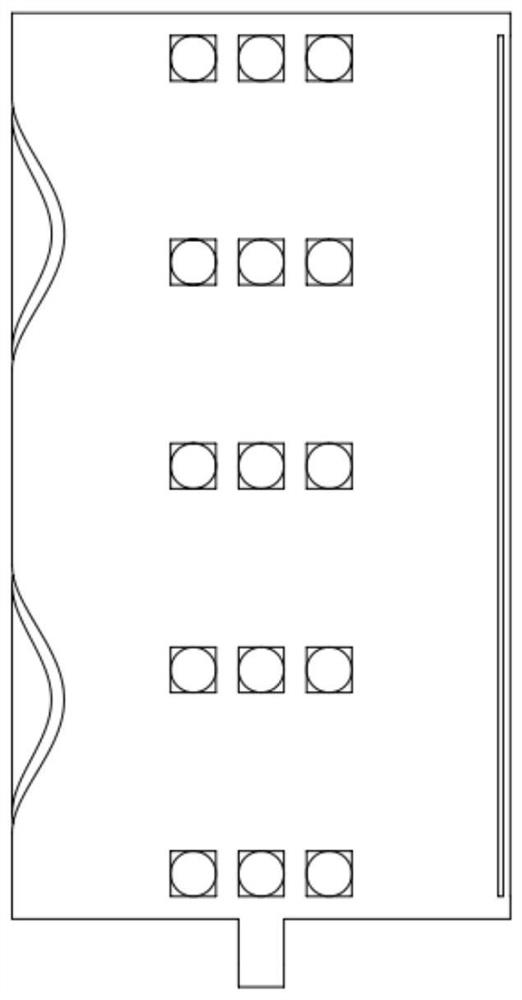

[0030] like Figure 1-3 As shown, the rotary fitting electrospinning device provided in this embodiment includes an outer hollow cylindrical spinneret 3 and an inner hollow cylinder 4 fitted therewith, and the spinning liquid supply device includes a digitally controlled micro-injection pump 1 connected to a syringe 2. The hose is connected to the inner hollow cylinder 4, and there are four different types of openings on the outer hollow cylinder spinneret 3, which are driven to rotate by the servo motor 6, and the inner hollow cylinder 4 is connected to the high-voltage positive electrode, when the outer hollow cylinder spinneret When the opening of 3 is connected with the opening of inner hollow cylinder 4, and the voltage exceeds a critical value, multiple electrospinning jets will be generated at the connected opening.

[0031] The inner hollow cylinder 4 is fixed horizontally and does not rotate with the rotation of the outer hollow cylinder spinneret, and the high-voltag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com