Method for producing a porous transport layer for an electrochemical cell

An electrochemical and transport layer technology, applied in electrochemical generators, components of fuel cells, fuel cells, etc., can solve the problems of complex and expensive technology, and achieve the effect of less consumption of metal materials and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

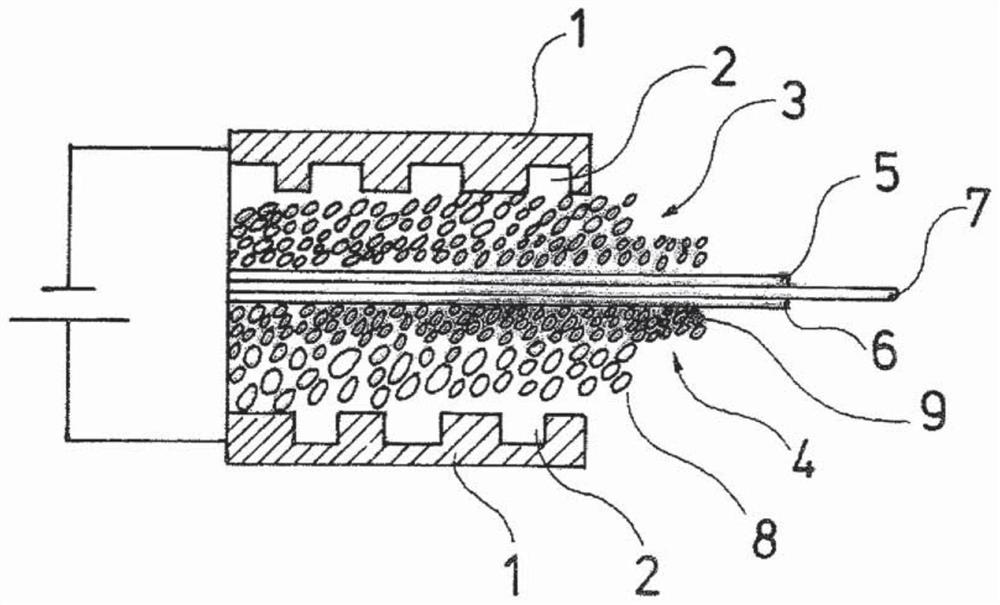

[0037] figure 1 The basic structure of a PEM electrolyzer is shown. The voltage for the generation of hydrogen and oxygen from water is applied to the two outer bipolar plates 1 , which have channels 2 for the supply of reactants, water, and for the removal of the reaction products hydrogen and oxygen. The channels 2 of the bipolar plate 1 opening towards the interior of the electrolyzer are covered by porous transport layers 3 , 4 which are electrically conductive and fluid-permeable. The porous transport layers 3 , 4 each contact in an electrically conductive manner on the catalyst layer 5 or 6 applied to the PEM 7 . In the electrolyzer shown here, for the generation of hydrogen and oxygen from water, there is a transport layer 4 of titanium on the anode side and a transport layer 3 of graphite on the cathode side. The catalyst layer 6 on the anode side is made of iridium oxide, and the catalyst layer 5 on the cathode side is made of platinum. Such a structure belongs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com