Production system of waterproof agent

A production system and waterproofing agent technology, which is applied in cocoa, grain processing, food science, etc., can solve the problems that the product quality level is greatly affected, affects the product performance quality level, and the product is mixed with large particle size materials, so as to improve the quality. Level and performance, improvement effect, effect of increasing the time of fine grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

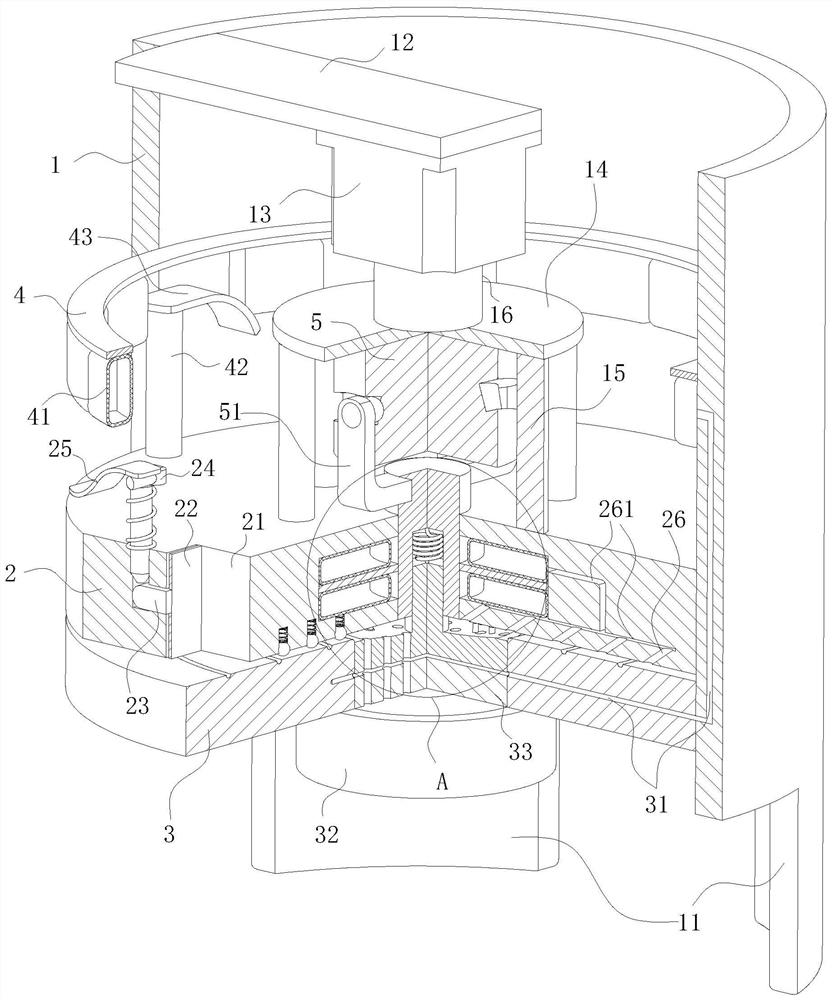

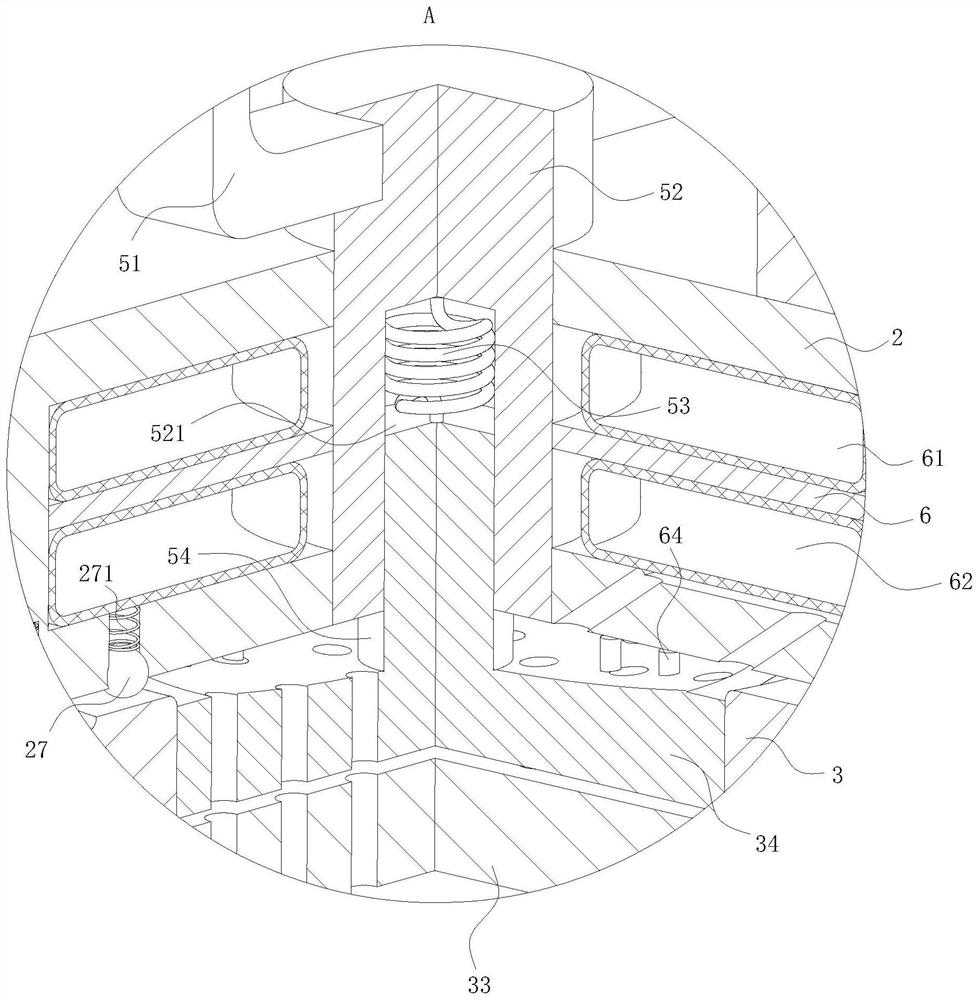

[0037] As an embodiment of the present invention, the sieve plate on the lower grinding plate 3 includes a lower sieve plate 33 and an upper sieve plate 34; the upper sieve plate 34 has the same specifications as the lower sieve plate 33; the lower sieve plate 33 passes Screw threads are fixedly connected on the lower grinding plate 3; the center line of the upper sieve plate 34 coincides with the center line of the lower sieve plate 33, and the upper surface of the upper sieve plate 34 is flush with the upper surface of the lower grinding plate 3; The sieve plate 34 can rotate relative to the lower grinding plate 3; the center position of the upper surface of the upper sieve plate 34 is fixedly connected with a spline column 54; the upper end of the spline column 54 is fixedly connected with the upper grinding plate 2;

[0038] When working, during the rotation of the upper grinding plate 2, the upper sieve plate 34 on the lower grinding plate 3 is connected with the upper gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com