Automatic quartz tube welding device and method

A quartz tube and welding technology, which is applied in glass reshaping, glass manufacturing equipment, glass forming, etc., can solve the problems of shortening the welding time of the tube cap and the cracking of the quartz tube, so as to reduce unsafe factors and improve the quality of crystal growth Improve and evenly heat the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

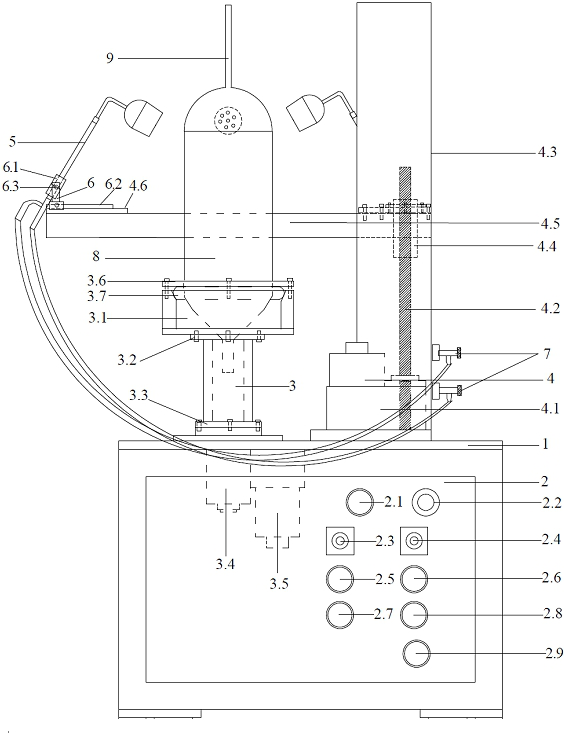

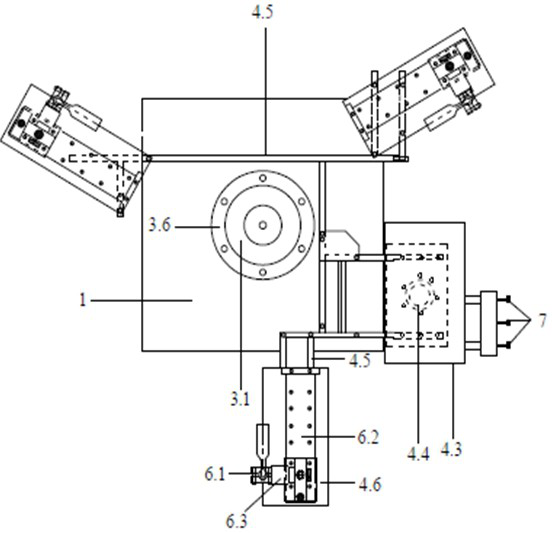

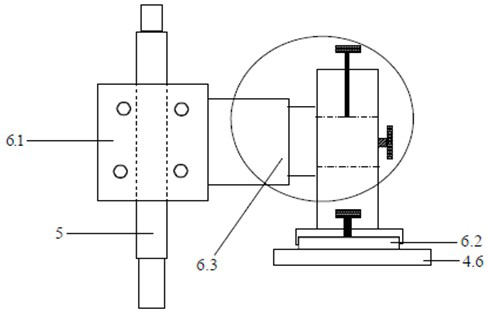

[0032] Such as figure 1 , figure 2 As shown, the device includes an operation table 1, a control panel 2, a stage rotating device 3, a hydrogen-oxygen welding torch moving device 4, a hydrogen-oxygen welding torch 5, a hydrogen-oxygen welding torch adjusting device 6 and a hydrogen-oxygen welding torch valve 7.

[0033] The control part on the control panel 2 of this device is provided with three groups, the first group is indicator light 2.1 and emergency stop button 2.2; Open button 2.5 and stage rotation close button 2.7; the third group is the hydrogen-oxygen welding torch movement control button 2.4, the hydrogen-oxygen welding torch moving up button 2.6, the hydrogen-oxygen welding torch moving down button 2.8 and the hydrogen-oxygen welding torch Welding torch movement stop button 2.9.

[0034] The stage rotation device 3 includes a quartz tube stage 3.1, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com