Micromolecular concrete retarder and preparation method thereof

A technology for concrete and setting retarder, applied in the field of concrete adjuvants, can solve the problems of concrete strength, workability, poor weather resistance, corruption and odor, etc., and achieves excellent compatibility, good weather resistance and long shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

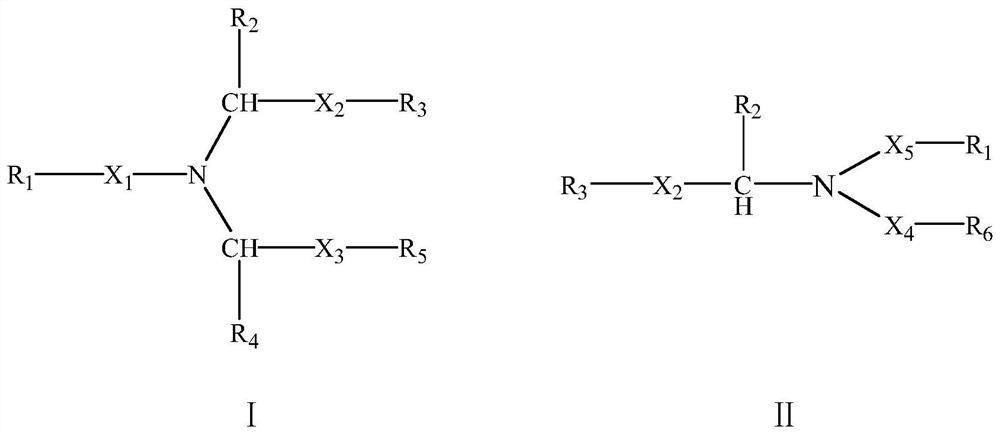

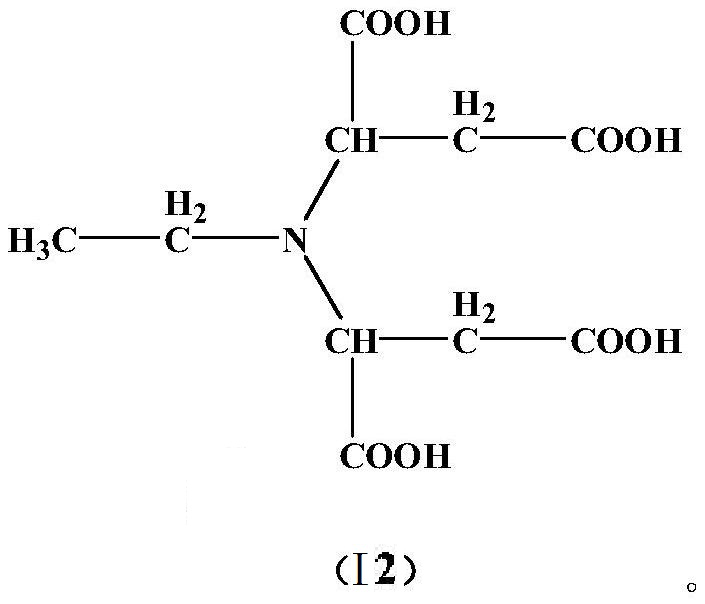

[0049] As a kind of small molecule concrete retarder of the embodiment of the present invention, the chemical structure of described small molecule concrete retarder is as formula (1);

[0050]

[0051] The preparation method of the small molecule concrete retarder described in the present embodiment may further comprise the steps:

[0052] (1) Mix 1.8 mol of serine and 4 mol of 4-pentenoic acid in 9 mol of deionized water to obtain a mixed system A, add 0.2 mol of concentrated sulfuric acid to adjust the pH value of the mixed system A to 0;

[0053] (2) Control the temperature of the mixing system A to 120°C and add 4 mol of the compound propionaldehyde dropwise to the mixing system A, stir at a constant speed, mix and keep warm for 120 minutes, and cool to obtain the small molecule concrete retarder described in this example.

Embodiment 2

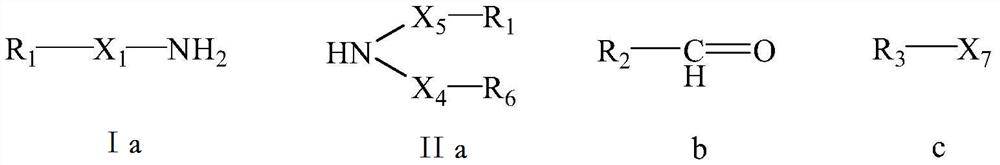

[0055] As a kind of small molecule concrete retarder of the embodiment of the present invention, the chemical structure of described small molecule concrete retarder is as formula (2);

[0056]

[0057] The preparation method of the small molecule concrete retarder described in the present embodiment may further comprise the steps:

[0058] (1) Mix 1.8mol ethylamine and 4.5mol acetic acid in 9mol deionized water to obtain mixed system A, add 0.2mol concentrated sulfuric acid to adjust the pH value of mixed system A to 0;

[0059] (2) Control the temperature of the mixing system A to 115°C and add 4.2 mol glyoxylic acid dropwise to the mixing system A, and stir at a constant speed, mix and keep warm for 60 minutes, and cool to obtain the small molecule concrete retarder described in this embodiment .

Embodiment 3

[0061] As a kind of small molecule concrete retarder of the embodiment of the present invention, the chemical structure of described small molecule concrete retarder is as formula (3);

[0062]

[0063] The preparation method of the small molecule concrete retarder described in the present embodiment may further comprise the steps:

[0064] (1) Mix 2 mol threonine and 4.2 mol 1-propanesulfonic acid in 9 mol deionized water to obtain a mixed system A, add 0.2 mol concentrated sulfuric acid to adjust the pH value of the mixed system A to 0;

[0065] (2) Control the temperature of the mixing system A to 125° C., add 4.2 mol propionaldehyde dropwise to the mixing system A, stir at a constant speed, mix and keep warm for 120 minutes, and cool to obtain the small molecule concrete retarder described in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com