A kind of photocatalytic ceramic and its preparation method and the method for degrading organic dye rhb

A technology of photocatalytic ceramics and organic dyes, applied in ceramic products, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of less functional research on waste ceramics and no photocatalytic ceramics, and achieve raw material costs Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] Dry and dehydrate the titanium slag, and then grind it to 325 mesh to obtain green body powder; add polyvinyl alcohol solution with a concentration of 5% to the green body powder and control the mass-volume ratio of the two to 15:1kg / L, Mix the powder and the solution to granulate, and take the granulated particles on the 40 mesh sieve under the 20 mesh sieve as the green body pellets; spread the green body pellets evenly in the mold, at 380kgf / cm 2 Press molding under a certain pressure to obtain a photocatalytic ceramic green body; put the green body into a kiln and heat it to 250°C at a heating rate of 2°C / min; then heat it to 1150°C at a heating rate of 5°C / min for sintering. And keep it at the sintering temperature for 60 minutes, cool to room temperature after the heat preservation is over, and obtain a series of photocatalytic ceramics after polishing.

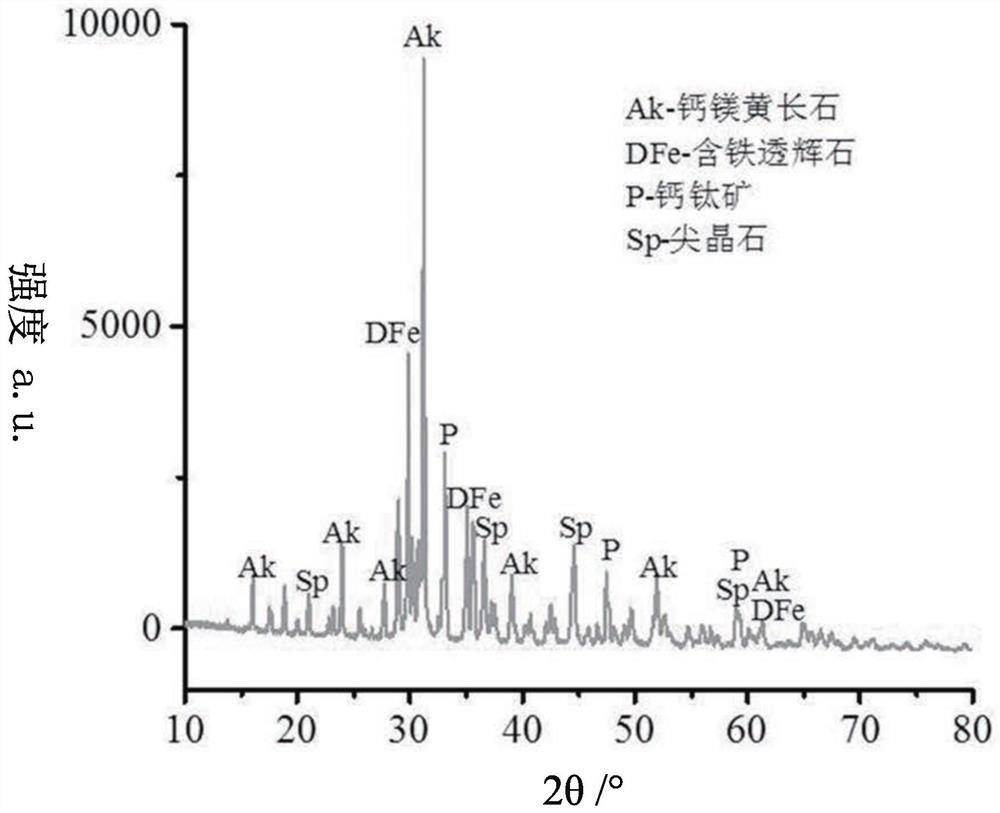

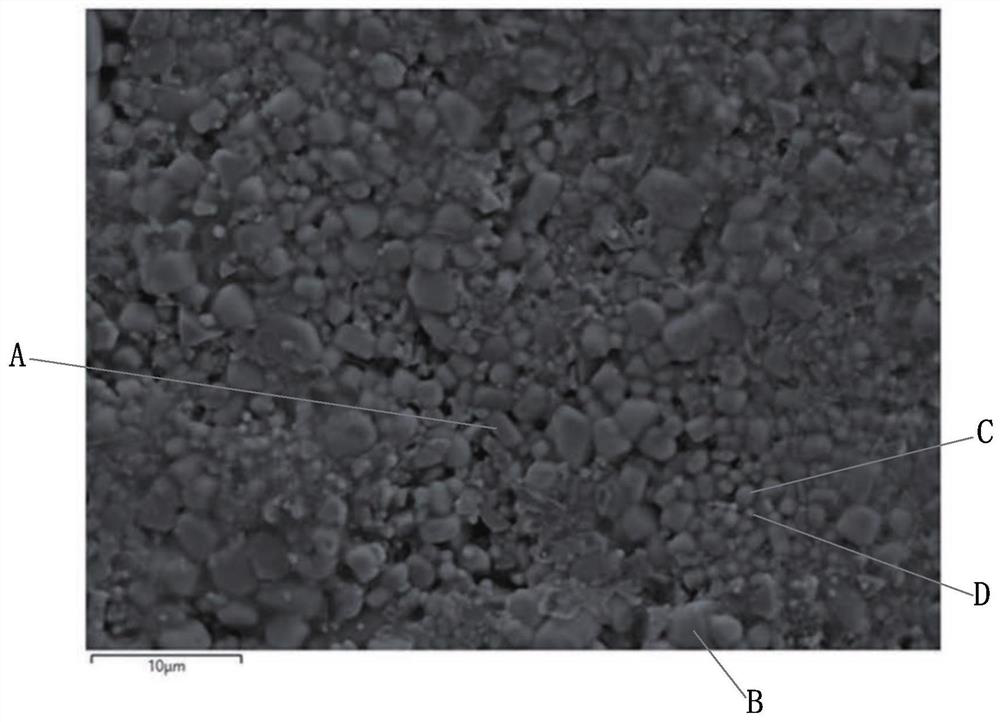

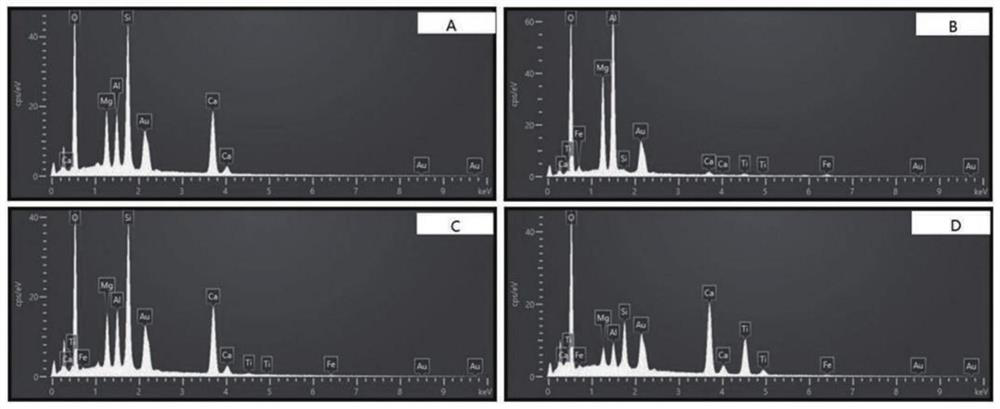

[0044] The main crystal phase of the prepared ceramic products is calcium magnesium feldspar phase, and the se...

example 2

[0046] Dry and dehydrate the titanium slag, and then grind it to 325 mesh to obtain green body powder; add polyvinyl alcohol solution with a concentration of 5% to the green body powder and control the mass-volume ratio of the two to 10:1kg / L, Mix the powder and the solution to granulate, and take the granulated particles on the 40 mesh sieve under the 20 mesh sieve as the green body pellets; spread the green body pellets evenly in the mold, at 345kgf / cm 2 Press molding under a certain pressure to obtain a photocatalytic ceramic green body; put the green body into a kiln and heat it to 250°C at a heating rate of 2°C / min to remove moisture from the green body; The heating rate of min was heated to 1180°C for sintering, and kept at the firing temperature for 60 minutes. After the heat preservation was completed, it was cooled to room temperature, and a series of photocatalytic ceramics were obtained after polishing.

[0047] Such as figure 1 As shown, the main crystal phase of ...

example 3

[0050] Dry and dehydrate the titanium slag, and then grind it to 200 mesh to obtain green body powder; add polyvinyl alcohol solution with a concentration of 8% to the green body powder, mix the powder and the solution to granulate, and mix the mass and volume of the two The ratio is controlled to be 20:1kg / L, and the mass-to-volume ratio of the two is controlled to be 10:1kg / L; 2 Press molding under a certain pressure to obtain a photocatalytic ceramic green body; put the green body into a kiln and heat it to 200°C at a heating rate of 3°C / min; then heat it to 1200°C at a heating rate of 15°C / min for sintering. And keep it at the sintering temperature for 15 minutes, cool to room temperature after the heat preservation is over, and obtain a series of photocatalytic ceramics after polishing.

[0051] The main crystal phase of the prepared ceramic product is calcium magnesium mellow feldspar phase, and the secondary crystal phase is iron-containing diopside phase, perovskite ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com