Water-based polyamide wax rheological additive with improved thermal stability and preparation method thereof

A technology of thermal stability additives and polyamide waxes, applied in the field of water-based rheological additives of coating additives, can solve the problems of loss of thickening and thixotropic properties, low molecular weight, and difficulty in re-establishing hydrogen bonds, etc., to achieve anti-sedimentation and the effect of reducing the anti-sag performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

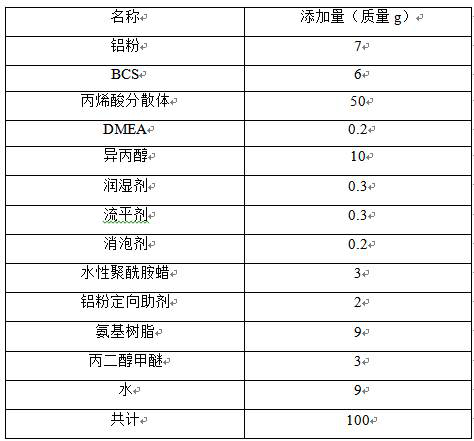

Embodiment 1

[0026] In a 1000ml four-neck flask, first add 2mol of 12-hydroxystearic acid, raise the temperature to 120°C, after the 12-hydroxystearic acid is completely melted, then add 1mol of 4,4'-diaminodicyclohexyl Methane, nitrogen, heated to 160 ° C to start the dehydration reaction until anhydrous out and the acid value of the reaction product ≦ 10 mgKOH / g to stop the reaction, the product was cooled to obtain a beige solid - thermal stability aid A1.

[0027] In a 500ml four-neck flask, first add 6g of heat stabilization additive A1 and 24g of water-based polyamide wax resin (polymerized from dimer acid and hexamethylenediamine) with an acid value of 75mgKOH / g, and then add 15g of propylene glycol monomethyl ether and 5g of propylene glycol n-propyl ether as an organic solvent, install an oil bath, a stirrer, a temperature controller and a spherical condenser, heat up to 110° C. and stir to dissolve at a constant temperature. After the above ingredients are dissolved, add 5g of N,...

Embodiment 2

[0029] In a 1000ml four-neck flask, first add 1mol of 12-hydroxystearic acid, 1mol of stearic acid, and heat up to 110°C. After the monobasic acid is completely melted, add 0.4mol of 3,3'-dimethyl- 4,4'-diaminodicyclohexylmethane, and blow nitrogen, heat up to 140°C to start the dehydration reaction, add 0.6mol 4,4'-diaminodicyclohexylmethane after reacting for 6 hours, heat up to 160°C to react until anhydrous The reaction is terminated when the acid value of the reaction product is less than or equal to 10 mgKOH / g, and the product is cooled to obtain a beige solid-thermal stabilization aid A2.

[0030]In a 500ml four-necked flask, first add 4g of heat stabilization additive A2, and 16g of water-based polyamide wax resin (made of dimer acid, 1,6 hexamethylenediamine and 1,10-decane) with an acid value of 90mgKOH / g Polymerized diamine), then add 16 grams of propylene glycol monobutyl ether as an organic solvent, install the oil bath, stirrer, temperature controller and spheric...

Embodiment 3

[0031] Example 3: In a 1000ml four-necked flask, first add 1.2mol of 12-hydroxystearic acid, 0.3mol of palmitic acid and 0.5mol of lauric acid and raise the temperature to 130°C. After the monobasic acid is completely melted, add 0.3 mol of dipolyamine, and blown with nitrogen, the temperature was raised to 150°C to start the dehydration reaction, and after 4 hours of reaction, 0.4 mol of 4,4'-diaminodicyclohexylmethane and 0.3 mol of 3,3'-dimethyl-4 , 4'-diaminodicyclohexylmethane, and heated to 170 ° C to react until anhydrous and the acid value of the reaction product ≦ 10 mgKOH / g, the reaction was terminated, and the product was cooled to obtain a beige solid A3.

[0032] First add 7g of active ingredient A3, and 33g of water-based polyamide wax resin (polymerized from dimer acid, sebacic acid, 1,6 hexamethylenediamine and p-phenylenediamine) with an acid value of 64mgKOH / g, and then add 18 grams of propylene glycol monobutyl ether and 6 g of propylene glycol monomethyl et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com