DC-DC power supply compensation control circuit based on voltage-controlled delay line

A DC-DC, control circuit technology, applied in control/regulating systems, electrical components, regulating electrical variables, etc., can solve the problems of limiting input/output operating voltage range, PWM controller failure, high power, etc., to achieve wide The effect of voltage output range, elimination of inherent delay, and simple circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

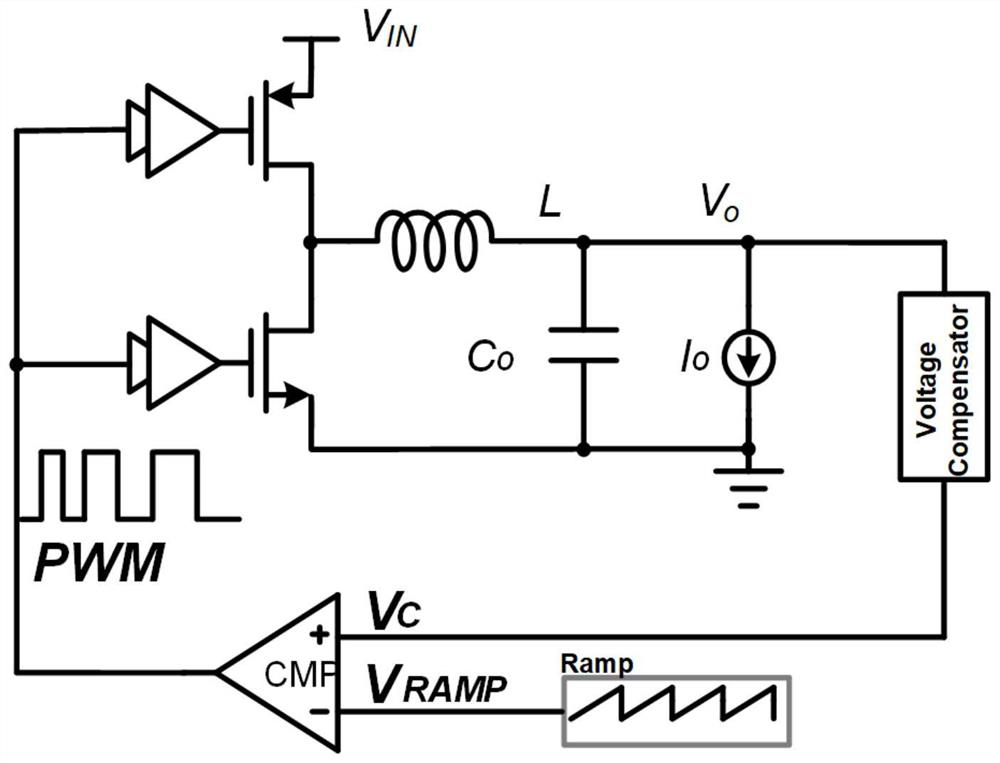

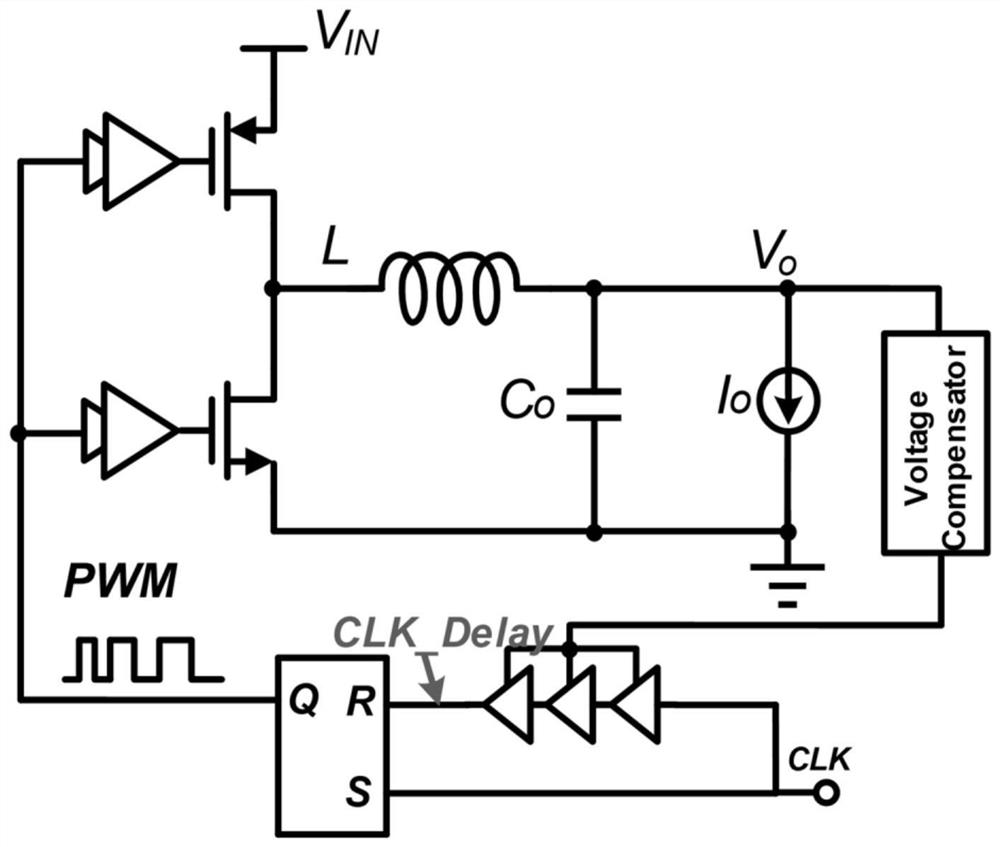

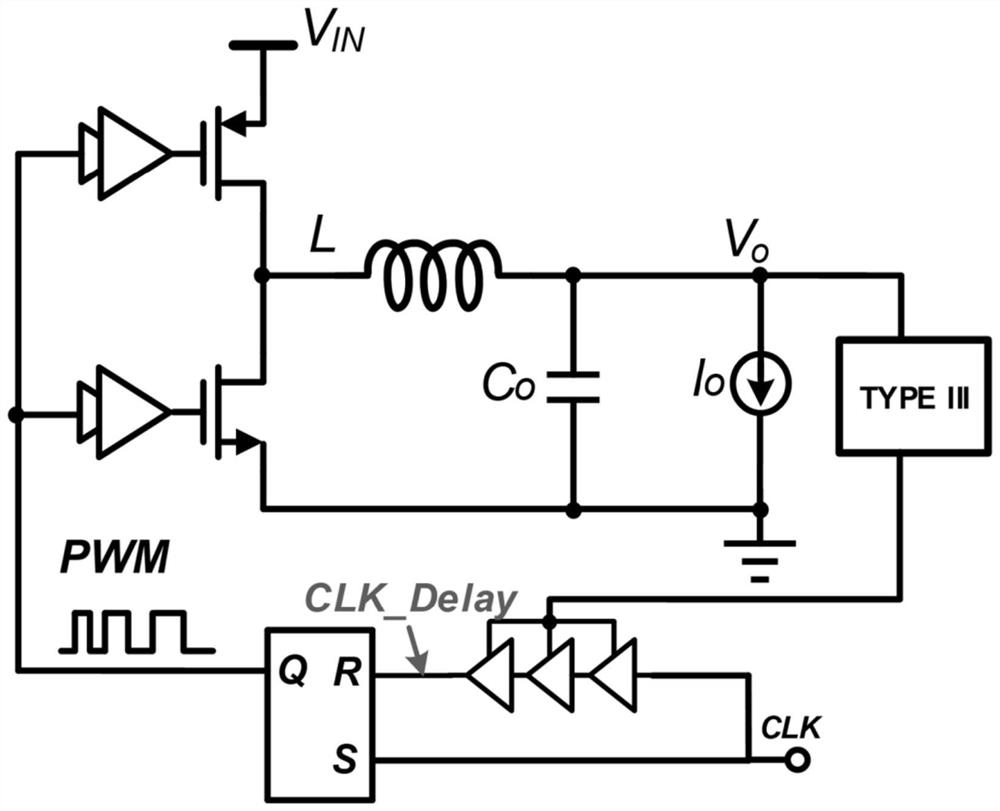

[0029] The present invention is based on the DC-DC power supply compensation scheme of the voltage-controlled delay line. The system includes a DC-DC power supply topology circuit, a drive circuit, a compensator, a voltage-controlled delay line and a logic control circuit, such as figure 2 As shown, the output voltage of the power stage of the DC-DC converter generates a feedback voltage through the voltage divider network, and the feedback voltage outputs the control voltage through the compensation network, which is used as the control signal of the voltage-controlled delay line. The external clock and the voltage-controlled delay line The output terminals of the RS flip-flop are respectively connected to the S terminal and R terminal of the RS flip-flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com