Biological reaction device and biological reaction method

A biological reaction device and biological reaction technology, which are applied in the methods of supporting/immobilizing microorganisms, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of inability to react to temperature control, unsatisfactory mixing effect of reactants, and environmental impact. and other problems, to achieve good axial mixing ability, improve mass transfer rate and dissolved oxygen rate, and reduce emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

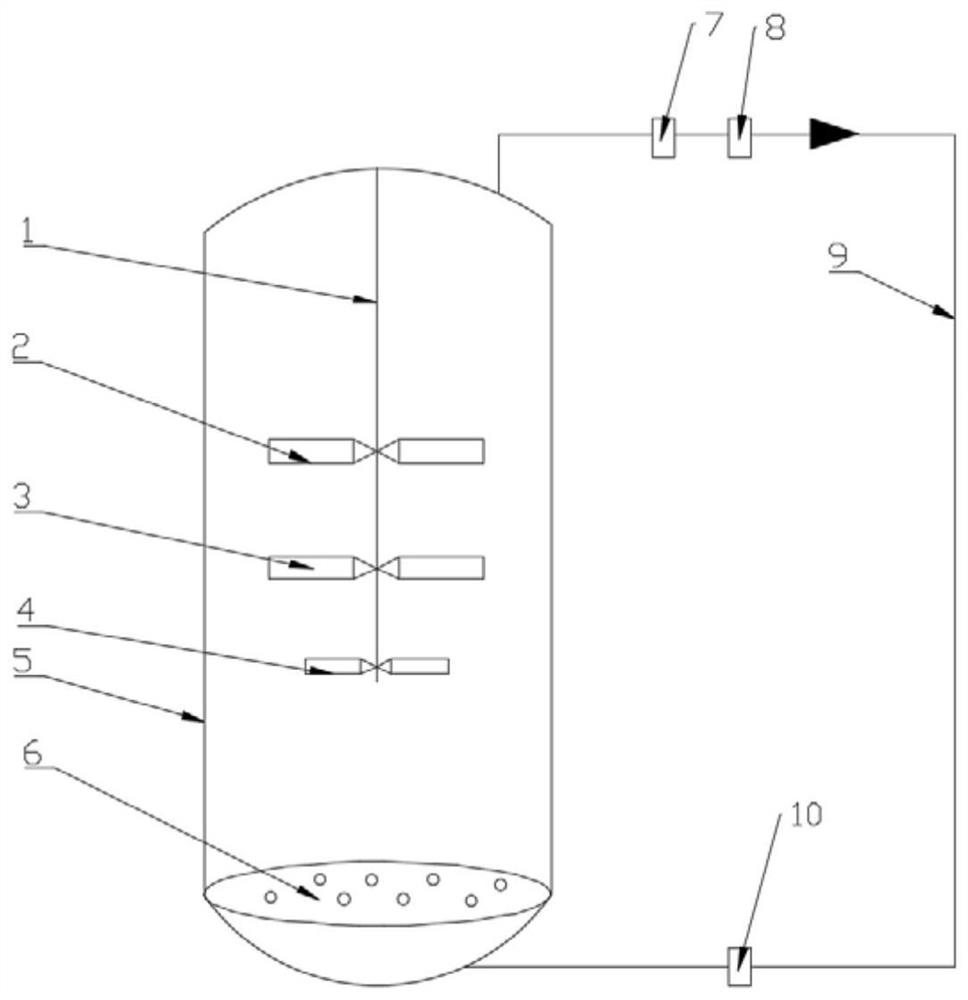

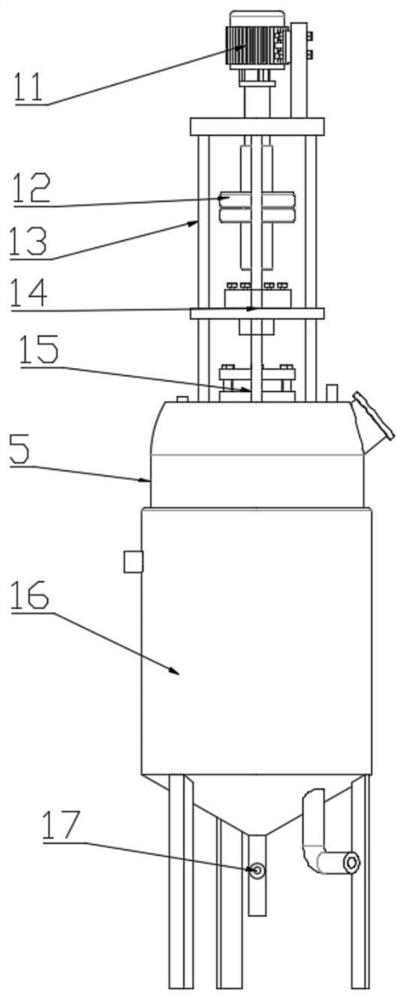

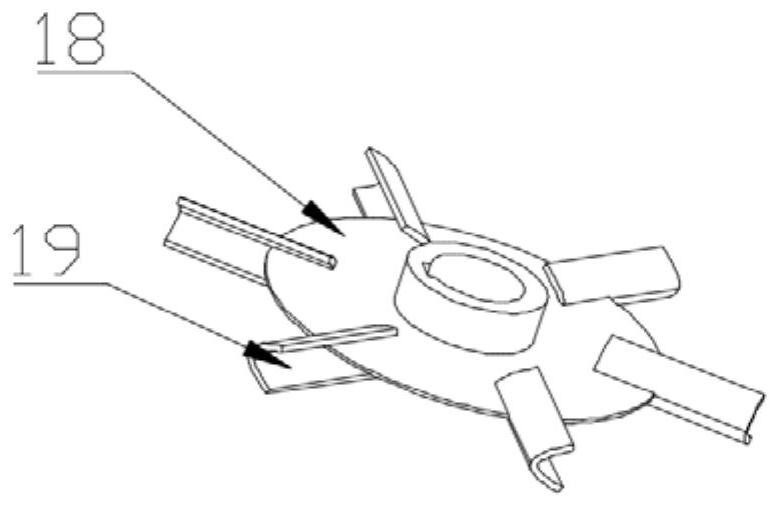

[0077] This embodiment provides a bioreactor, which is based on a bioreactor provided in a specific embodiment, wherein, the stirring shaft 1 is provided with a parabolic stirring paddle 2 and a first airfoil axial flow paddle sequentially from top to bottom. 3 and the second airfoil axial flow paddle 4, the diameter of the first airfoil axial flow paddle 3 is greater than the diameter of the second airfoil axial flow paddle 4, 16 nozzles are evenly arranged on the jet flow plate, and the remaining structures are the same as a specific embodiment The bioreactors are identical.

[0078] This embodiment also provides a method for performing a biological reaction using the above-mentioned biological reaction device, based on the biological reaction method provided in a specific embodiment, wherein the reaction temperature is 37 ° C, the pressure inside the housing 5 is 0.4 MPa, and the remaining operating steps and parameters are the same as in the biological reaction method desc...

Embodiment 2

[0081] This embodiment provides a bioreactor, based on the bioreactor provided in a specific embodiment, wherein, the stirring shaft 1 is provided with a first parabolic stirring paddle 2 and an airfoil axial flow paddle sequentially from top to bottom. With the second parabolic paddle 2, the diameter of the first parabolic paddle 2 is the same as the diameter of the second parabolic paddle 2, and 9 nozzles are evenly arranged on the jet flow plate, and all the other structures are the same as those described in a specific embodiment. The bioreactor setup is identical.

[0082] This embodiment also provides a method for performing a biological reaction using the above-mentioned biological reaction device, based on the biological reaction method provided in a specific embodiment, wherein the reaction temperature is 4 ° C, the pressure inside the housing 5 is 0.1 MPa, and the remaining operating steps and parameters are the same as in the biological reaction method described in ...

Embodiment 3

[0085] This embodiment provides a bioreactor, which is based on a bioreactor provided in a specific embodiment, wherein the stirring shaft 1 is provided with a first airfoil axial flow paddle 3 and a second airfoil paddle from top to bottom. Axial flow paddle 4 and parabolic stirring paddle 2, the diameter of the first airfoil axial flow paddle 3 is greater than the diameter of the second airfoil axial flow paddle 4, 12 nozzles are evenly arranged on the jet flow plate, and the remaining structures are the same as a specific embodiment The bioreactors are identical.

[0086] This embodiment also provides a method for carrying out a biological reaction using the above-mentioned biological reaction device, based on the biological reaction method provided in a specific embodiment, wherein the reaction temperature is 60 ° C, the pressure inside the housing 5 is 0.05 MPa, and the remaining operating steps and parameters are the same as in the biological reaction method described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com