Method for improving the color and texture quality of vacuum freeze-dried reconstituted strawberry chips

A vacuum freeze-drying and strawberry technology, which is applied in the direction of food freezing, food drying, and the function of food ingredients, etc., can solve the problems of unstable storage period of geranidin-3-glucoside, low hardness and brittleness of products, and improve chemical Stability, improvement of stability, effect of inhibiting degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

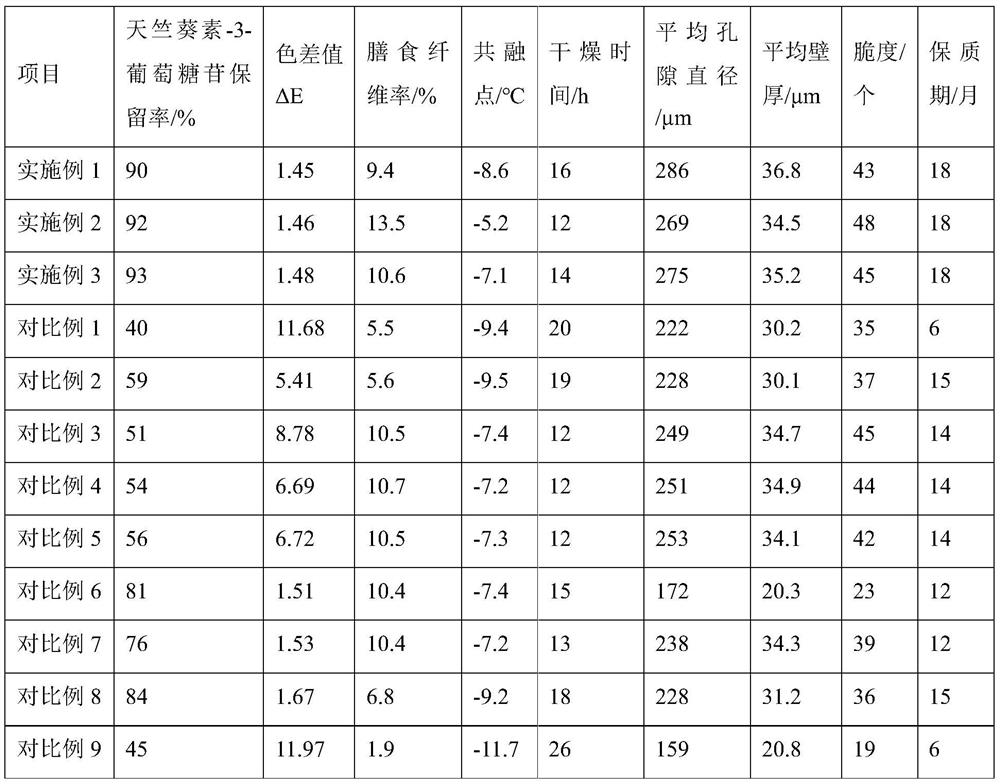

Embodiment 1

[0027] A method for improving the color and quality of vacuum freeze-dried recombined strawberry chips, comprising the following steps:

[0028] Pretreatment: Select strawberries with uniform maturity and no pests and diseases, wash them, and drain the water through a vibrating sieve;

[0029] Mixing and beating: mixing strawberries and apple pomace, and then beating in a beater to obtain strawberry pulp. The mass fraction of apple pomace in the strawberry pulp is 5%.

[0030] Preparation: Add low-ester pectin and protocatechuic acid (3,4-dihydroxybenzoic acid) to strawberry pulp, and add citric acid to adjust the pH to 3.0 to obtain material A, wherein the mass ratio of strawberry pulp to pectin is 1:0.02, the mass concentration of protocatechuic acid in material A is 0.1g / kg;

[0031] Homogenization: Homogenize material A;

[0032] Remodeling: Pour the homogenized material A into the mold groove of the mold tray;

[0033] Freezing: Place the mold tray in a freezer at -18°...

Embodiment 2

[0039] A method for improving the color and quality of vacuum freeze-dried recombined strawberry chips, comprising the following steps:

[0040] Pretreatment: Select strawberries with uniform maturity and no pests and diseases, wash them, and drain the water through a vibrating sieve;

[0041] Mixing and beating: mixing strawberries and apple pomace, and then beating in a beater to obtain strawberry pulp. The mass fraction of apple pomace in the strawberry pulp is 10%;

[0042] Preparation: Add low-ester pectin and protocatechuic acid (3,4-dihydroxybenzoic acid) to strawberry pulp, and add citric acid to adjust the pH to 3.8 to obtain material A, wherein the mass ratio of strawberry pulp to pectin is 1:0.08, the mass concentration of protocatechuic acid in material A is 1.0g / kg;

[0043] Homogenization: Homogenize material A;

[0044] Remodeling: Pour the homogenized material A into the mold groove of the mold tray;

[0045] Freezing: Place the mold tray in a freezer at -18°C...

Embodiment 3

[0051] A method for improving the color and quality of vacuum freeze-dried recombined strawberry chips, comprising the following steps:

[0052] Pretreatment: Select strawberries with uniform maturity and no pests and diseases, wash them, and drain the water through a vibrating sieve;

[0053] Mixing and beating: mixing strawberries and apple pomace, and then beating in a beater to obtain strawberry pulp, the mass fraction of apple pomace in the strawberry pulp is 8%;

[0054] Preparation: Add low-ester pectin and protocatechuic acid (3,4-dihydroxybenzoic acid) to strawberry pulp, and add citric acid to adjust the pH to 3.4 to obtain material A, wherein the mass ratio of strawberry pulp to pectin is 1:0.05, the mass concentration of protocatechuic acid in material A is 0.5g / kg;

[0055] Homogenization: Homogenize material A;

[0056] Remodeling: Pour the homogenized material A into the mold groove of the mold tray;

[0057] Freezing: Place the mold tray in a freezer at -18°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com