Machine tool cutter temperature control device

A temperature control device and cutting tool technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of cutting fluid cooling, polluting the environment, and difficult recycling, so as to achieve the goal of clean production and ensure cutting quality , power controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

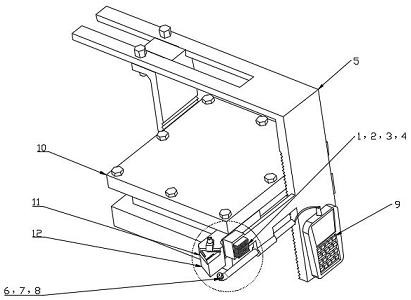

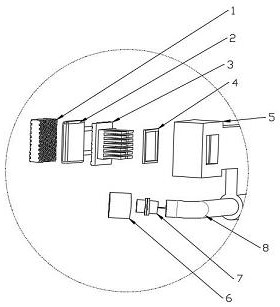

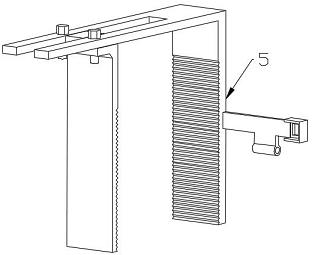

[0014] A machine tool tool temperature control device, characterized in that it includes a cooling block 1, a cooling semiconductor 2, a radiator 3, a rubber gasket 4, a movable fixture 5, a temperature sensor 7, an adjustable sleeve 8, a controller assembly 9, and a guide The cold block 1 is close to the handle 12, and the heat-conducting silicone grease is used as the contact medium in the middle. The cooling side of the cooling semiconductor 2 is close to the cold guide block 1, the heat dissipation side is close to the radiator 3, and the fin side of the radiator 3 is covered with a rubber gasket 4. During installation, first put the rubber gasket 4 into the fixed frame at the front end of the movable fixture 5; in the second step, install the radiator 3, and one side of the fins of the radiator 3 passes through the rubber gasket 4 and the frame opening of the fixed frame in turn; the third step, Install the cooling semiconductor 2, apply heat-conducting silicone grease on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com