A kind of preparation method of wood-based solar energy seawater desalination material

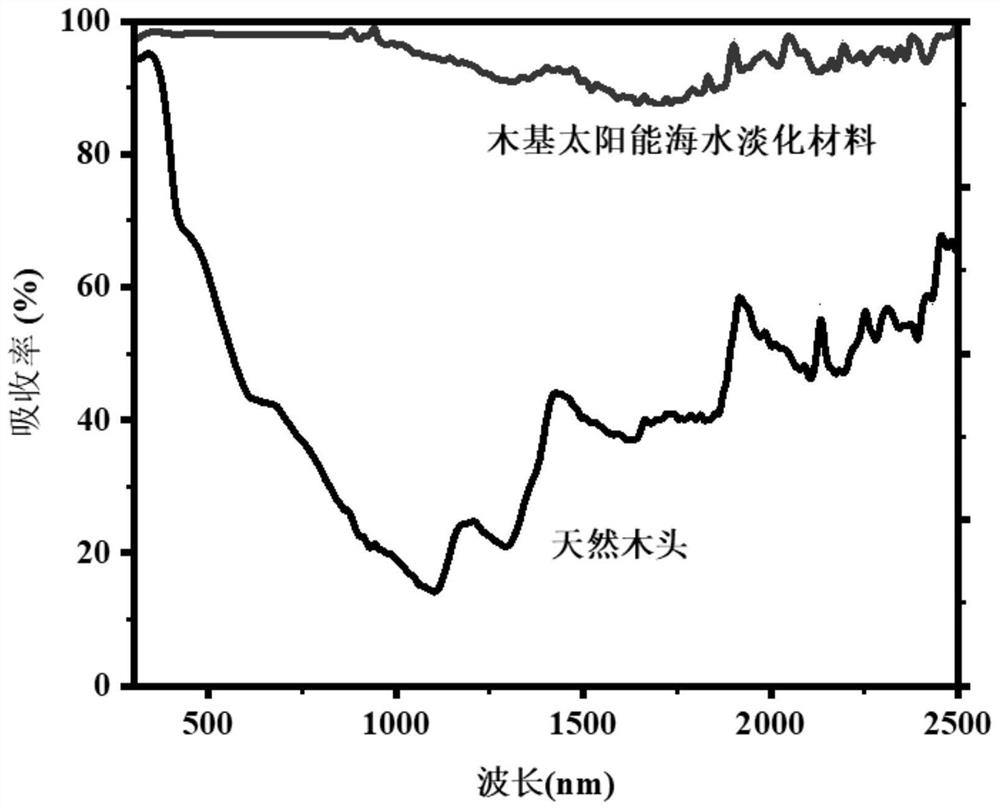

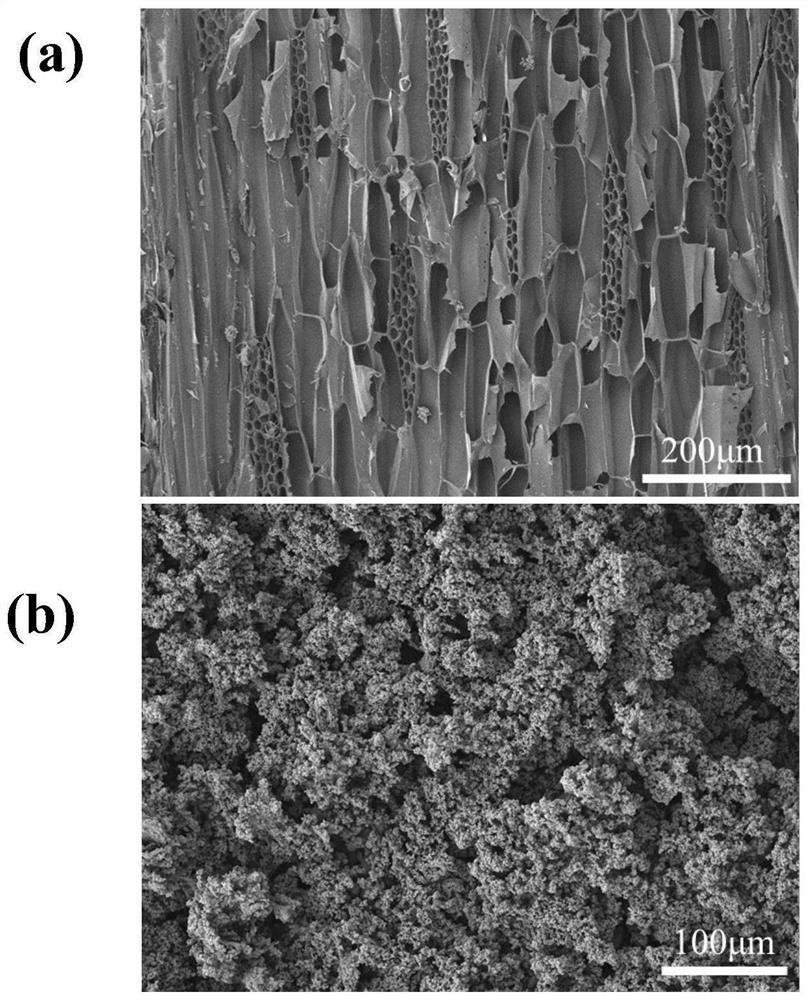

A solar and wood-based technology, applied in the field of solar seawater desalination, can solve the problems of limited large-scale application, complex preparation process, expensive price, etc., and achieve excellent thermal insulation performance, high solar energy absorption rate, and lightweight structural thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

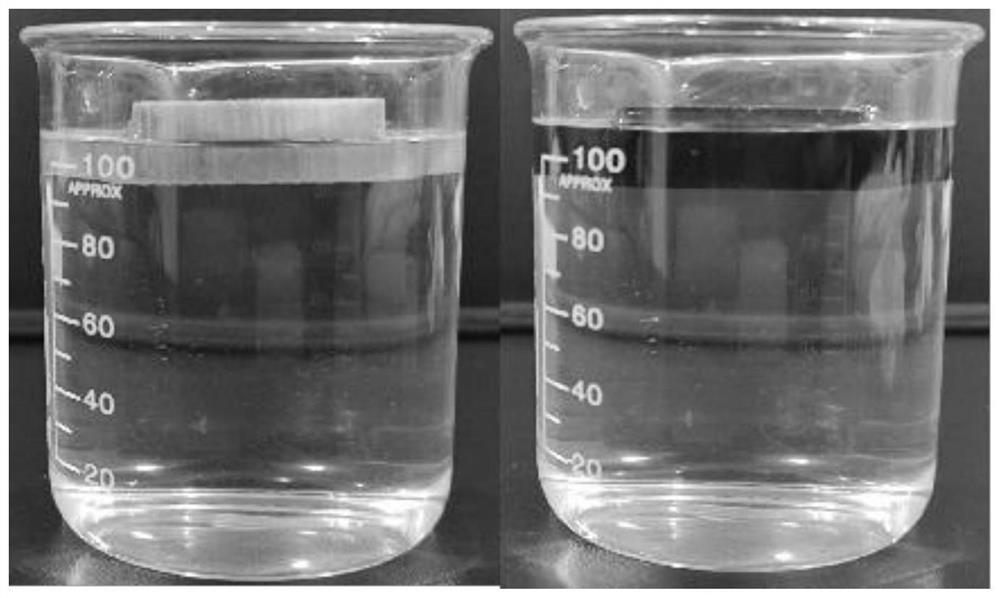

[0024] A preparation method of wood-based solar energy desalination seawater material, comprising the following steps:

[0025] (a) Cut the wood transversely along the growth direction, and the cutting size is 3cm×3cm×1cm (longitudinal × tangential × radial);

[0026] (b) ultrasonically cleaning the cut wood sample with deionized water for 15min, and then soaking it in a dilute sulfuric acid solution with a concentration of 1mol / L for 10min;

[0027] (c) directly immersed in potassium permanganate solution with a concentration of 0.2mol / L after taking out, the immersion time is 30min, then transferred to a constant temperature water bath and heated for 1h at a heating temperature of 60°C;

[0028] (d) After heating, take out the wood sample, wash the excess potassium permanganate on the surface and the potassium salt generated by the reaction with ethanol and deionized water respectively, and dry in a vacuum drying oven at a drying temperature of 40 °C and a drying time of 12 ...

Embodiment 2

[0032] A preparation method of wood-based solar energy desalination seawater material, comprising the following steps:

[0033] (a) Cut the wood transversely along the growth direction, and the cutting size is 3cm×3cm×1cm (longitudinal × tangential × radial);

[0034] (b) ultrasonically cleaning the cut wood samples with deionized water for 20 minutes, and then soaking them in a dilute sulfuric acid solution with a concentration of 0.1 mol / L for 30 minutes;

[0035] (c) after taking out, directly soak in potassium permanganate solution with a concentration of 0.1mol / L, soaking time is 40min, then transfer to constant temperature water bath and heat for 1h, heating temperature is 70℃;

[0036] (d) After heating, take out the wood sample, wash the excess potassium permanganate on the surface and the potassium salt generated by the reaction with ethanol and deionized water respectively, and dry in a vacuum drying oven at a drying temperature of 60 °C and a drying time of 6 h . ...

Embodiment 3

[0039] A preparation method of wood-based solar energy desalination seawater material, comprising the following steps:

[0040] (a) Cut the wood transversely along the growth direction, and the cutting size is 3cm×3cm×1cm (longitudinal × tangential × radial);

[0041] (b) ultrasonically cleaning the cut wood sample with deionized water for 25min, and then soaking it in a dilute sulfuric acid solution with a concentration of 0.5mol / L for a soaking time of 20min;

[0042] (c) after taking out, directly immersed in potassium permanganate solution with a concentration of 0.02mol / L, the immersion time is 60min, then transferred to a constant temperature water bath and heated for 2h, and the heating temperature is 80°C;

[0043] (d) After heating, take out the wood sample, wash the excess potassium permanganate on the surface and the potassium salt generated by the reaction with ethanol and deionized water respectively, and dry in a vacuum drying oven at a drying temperature of 80 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com