Advanced treatment method and system for landfill leachate evaporation effluent

A technology for landfill leachate and advanced treatment, which is applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. It can solve the problems of high cooling energy consumption, unsatisfactory treatment effect, and temperature influence. , to achieve the effect of saving energy consumption, ideal processing effect and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

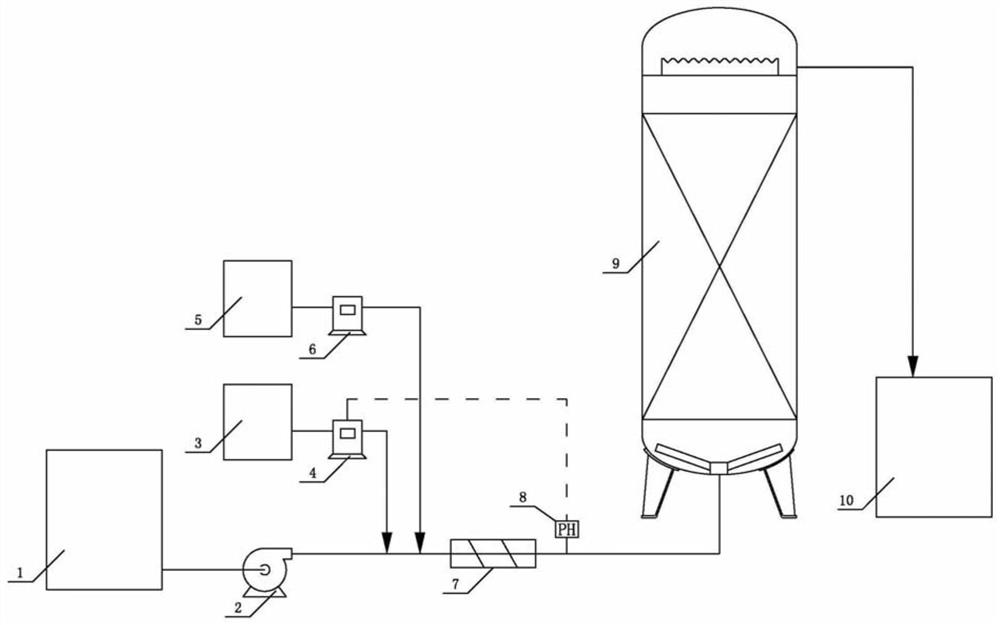

[0028] This embodiment discloses a high-temperature catalytic oxidation advanced treatment system for evaporating water from landfill leachate, its structure is as follows figure 1 As shown, it includes distilled water tank 1, distilled water pump 2, acid liquid tank 3, acid metering pump 4, hydrogen peroxide dosing tank 5, hydrogen peroxide dosing metering pump 6, pipeline mixer 7, pH detector 8, catalytic oxidation reaction tower 9. High temperature outlet tank 10 and control unit.

[0029] The distilled water tank 1 is used to hold the evaporated water from landfill leachate, the acid liquid tank 3 is used to hold sulfuric acid and / or nitric acid, and the hydrogen peroxide dosing tank 5 is used to hold 10-27%wt hydrogen peroxide Solution; the outlet of the distilled water tank 1, the outlet of the acid tank 3, and the outlet of the hydrogen peroxide dosing tank 5 are communicated with the pipeline mixer 7 through the distilled water pump 2, the acid metering pump 4 and the ...

Embodiment 2

[0035] This embodiment discloses a high-temperature catalytic oxidation advanced treatment method and system for evaporating water from landfill leachate, using the system described in Embodiment 1, including the following steps:

[0036] The landfill leachate with an organic matter content of 168 mg / L in the distilled water tank 1 evaporates water, and the water temperature of the evaporated water is 95° C., 8% dilute sulfuric acid in the acid tank 3, and 27% wt hydrogen peroxide solution in the hydrogen peroxide dosing tank 5, pass through the acid solution Dilute sulfuric acid in the tank 3 adjusts the pH value of the evaporated water to 6.0, and the dosage of hydrogen peroxide is hydrogen peroxide: organic matter=2.5:1 (w / w), and the reaction is carried out in the catalytic oxidation reaction tower 9 under high temperature conditions, and the reaction time is 1.5 hours. Finally, the effluent overflows into the high-temperature effluent tank, the organic matter content in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com