A kind of ultra-high ductility concrete used in earthquake-resistant engineering and its preparation method

A concrete, ultra-high technology, applied in the field of building materials, to achieve the effect of excellent seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

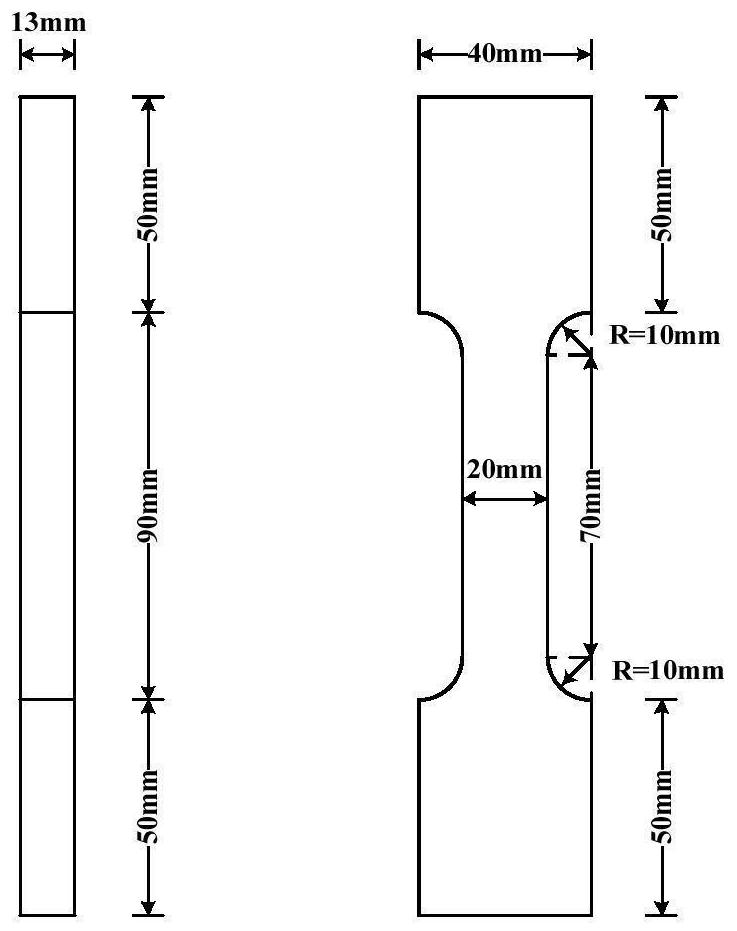

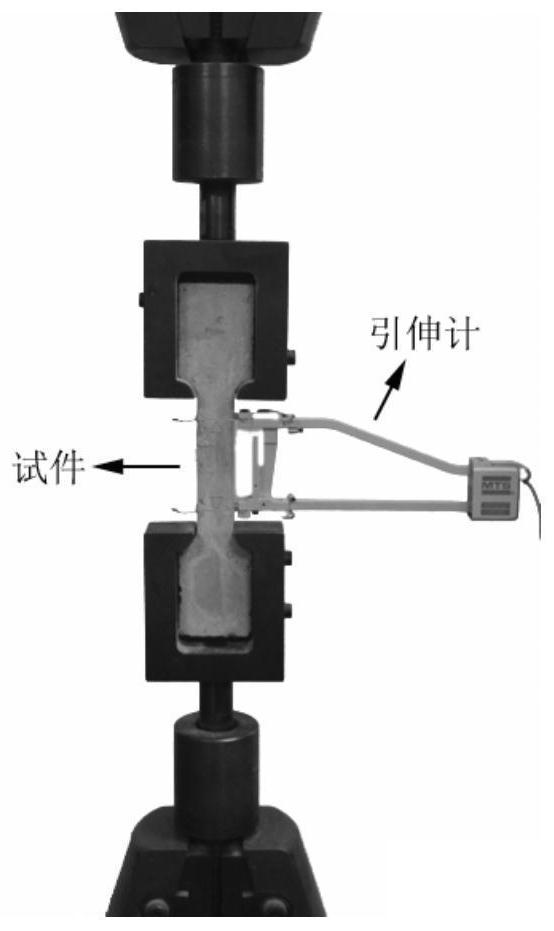

Image

Examples

Embodiment 1

[0049] The ultra-high ductility concrete of the present invention, its raw material is by cement, silica fume, mineral powder, quartz sand, polyethylene (PE) fiber, calcium carbonate whisker, polycarboxylate superplasticizer, hydroxyethyl cellulose, inorganic glue Coagulant, defoamer and water composition, each raw material all meets the requirement in the summary of the invention, implements according to the mixing ratio of Table 1.

[0050] Table 1 Example 1 used mix ratio (kg / m 3 , where the cement is P·O 52.5 ordinary Portland cement)

[0051]

[0052] (1) Accurately weigh raw materials by the mix ratio shown in Table 1 during implementation;

[0053] (2) Mix 20% water with calcium carbonate whiskers and hydroxyethyl cellulose, and use an integrated ultrasonic processor (brand: Fangxie, model: PZ-2000L) to ultrasonically disperse for 15 minutes to obtain material A;

[0054] (3) Mix polycarboxylate high-efficiency water reducer and inorganic gelling agent with 10% wat...

Embodiment 2

[0065] The raw materials used in this example are the same as those in Example 1, and the proportions in Table 3 are used. The preparation process and testing methods are all the same as in Example 1.

[0066] Table 3 Example 2 used mix ratio (kg / m 3 , where the cement is P·O 52.5 ordinary Portland cement)

[0067]

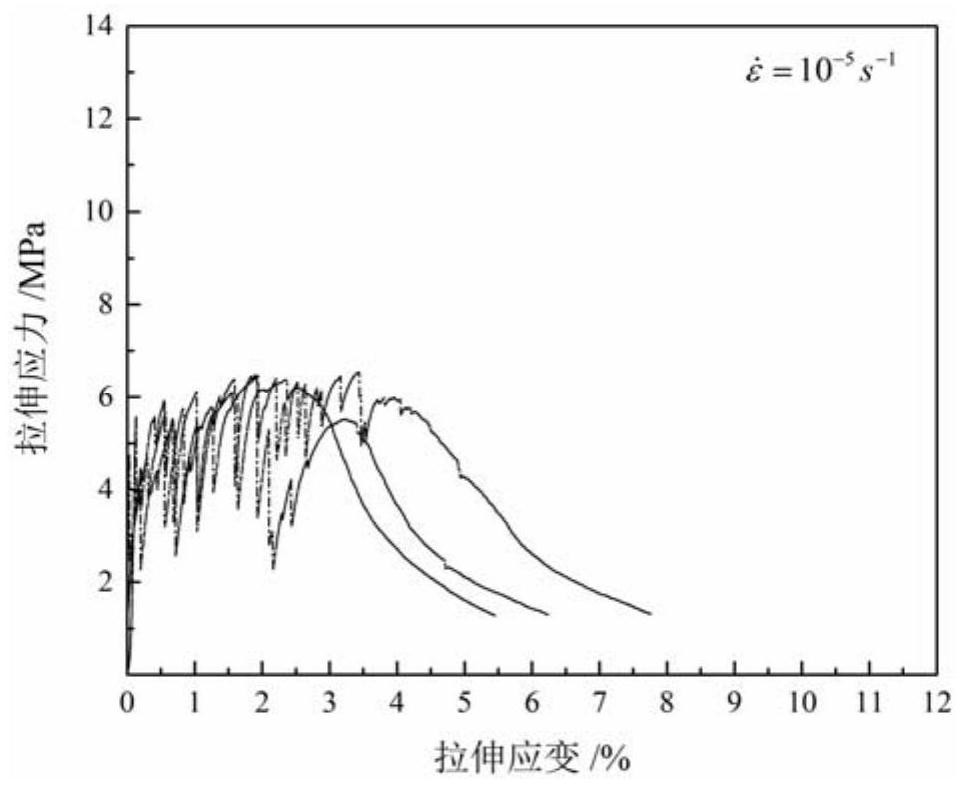

[0068] The test effect of this embodiment: the embodiment is at a strain rate of 10 -5 the s -1 、10 -4 the s -1 、10 -3 the s -1 and 10 -2 the s -1 The results of tensile strength and ultimate tensile strain are shown in Table 4. By comparison, it can be seen that the ultimate tensile strain of the PE-UHDC material provided in this embodiment also shows a trend of not falling but rising with the increase of strain rate, by ε&=1×10 -5 the s -1 When the 1.6% increase is ε&=1×10 -2 the s -1 When the 2.7%, an increase of 68.7%. However, compared with Example 1, the strength and ultimate tensile strain of the PE-UHDC material provided in this example are...

Embodiment 3

[0072] The raw materials used in this example are the same as those in Example 1, and the proportions in Table 5 are used. The preparation process and testing methods are all the same as in Example 1.

[0073] Table 5 Example 3 used mix ratio (kg / m 3 , where the cement is P·O 52.5 ordinary Portland cement)

[0074]

[0075] The test effect of this embodiment: the embodiment is at a strain rate of 10 -5 the s -1 、10 -4 the s -1 、10 -3 the s -1 and 10 -2 the s -1 The results of tensile strength and ultimate tensile strain are shown in Table 6. By comparison, it can be seen that the ultimate tensile strain of the PE-UHDC material provided in this embodiment also shows a trend of not falling but rising with the increase of strain rate, by ε&=1×10 -5 the s -1 When the 3.3% increase is ε&=1×10 -2 the s -1 When the 5.0%, an improvement of 51.5%. Compared with Example 1, the strength and ultimate tensile strain of the PE-UHDC material provided in this example are lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com