A chip-scale package structure and manufacturing method for moisture-sensitive high color gamut backlight application

A chip-level packaging and manufacturing method technology, applied in the field of backlight, can solve the problems of poor operation performance of the sorting machine, easy scratches on the surface of the package body, poor thermal conductivity of silica gel, etc., and achieves easy sorting machine operation, excellent heat resistance and other problems. performance, the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

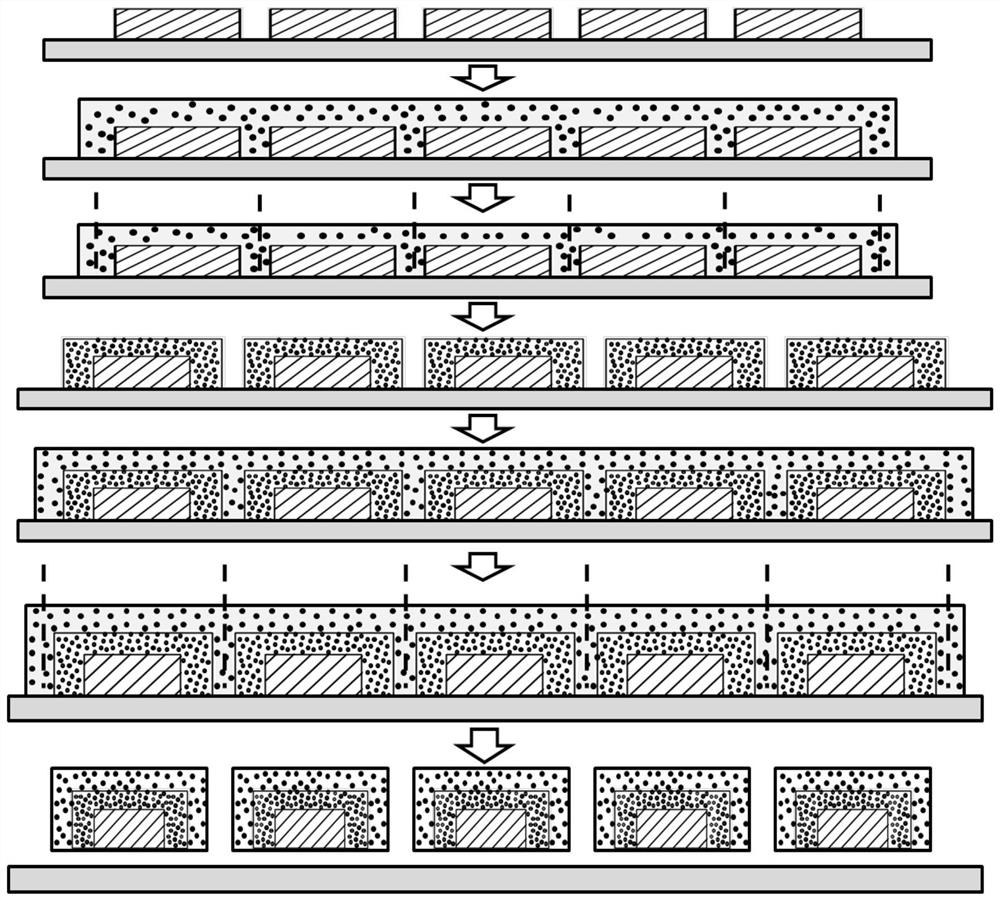

Method used

Image

Examples

Embodiment Construction

[0037]The technical solutions of the present invention will be further described below in conjunction with specific embodiments. Those skilled in the art can easily understand the advantages of the present invention through the content in the specification. Before further describing the specific embodiments of the present invention, it should be understood that the scope of protection of the present invention is not limited to the following specific examples; the experimental methods that do not indicate specific conditions in the following examples are usually according to conventional conditions, or according to conditions recommended by the manufacturer. When the examples give numerical ranges, it should be understood that, unless otherwise stated in the present invention, the two endpoints of each numerical range and any value between the two endpoints can be selected.

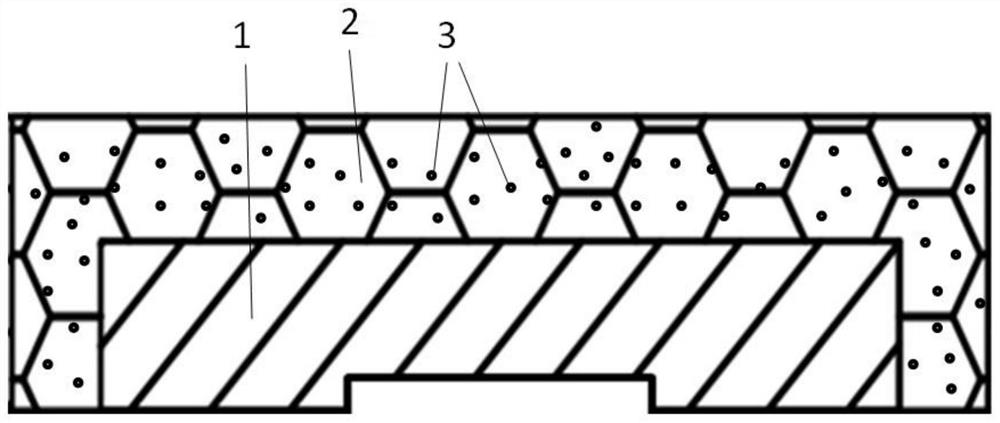

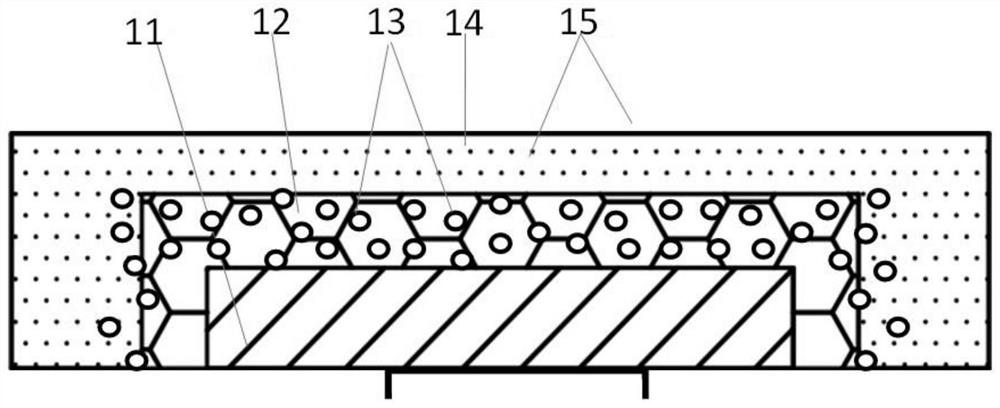

[0038] figure 1 It is a structural schematic diagram of a common five-sided light-emitting CSP in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com