Preparation method of high-quality 1, 3-cyclohexanedione product

A cyclohexanedione, high-quality technology, applied in the field of chemical synthesis, can solve the problems of difficult storage, low overall content, 1,3-cyclohexanedione appearance, quality problems, etc., and achieve the effect of not easy to change color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

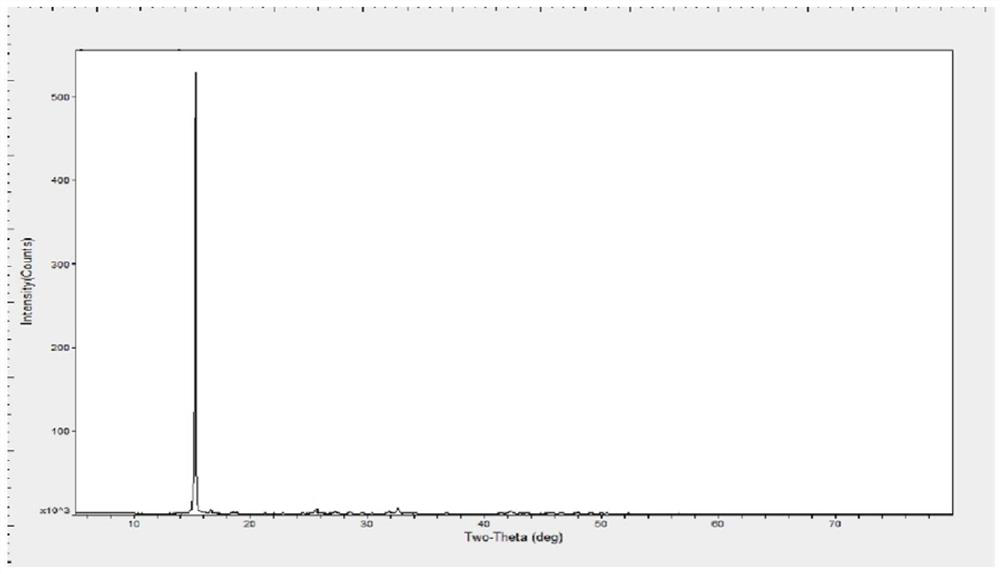

[0030] Preparation of high-quality seed crystals: 400kg of 1,3-cyclohexanedione solid (i.e., for example, the 1,3-cyclohexanedione solid prepared in Comparative Example 1 of the present invention) and 1000kg of toluene were added to a 1500L enamel kettle, and stirred Heat to 40°C, after all dissolves, cool down to 0-5°C, solids slowly precipitate out, continue to stir for 2 hours, discharge the feed liquid into a three-in-one filter to filter dry, and discharge the feed into a dryer after drying. Material, obtain the white powdery crystal of moisture content about 0.08%. The purity is 99.97% (HPLC purity, the same below), the yield is 98.11%, and the inorganic salt content is 0.21%. The obtained product was placed in a constant temperature and humidity chamber (temperature 35° C., humidity 40%) for 3 months without discoloration, caking and the like. Carry out powder XRD analysis to described white powdery crystal, the result sees figure 1 . The white powder crystal is the ...

experiment example 2

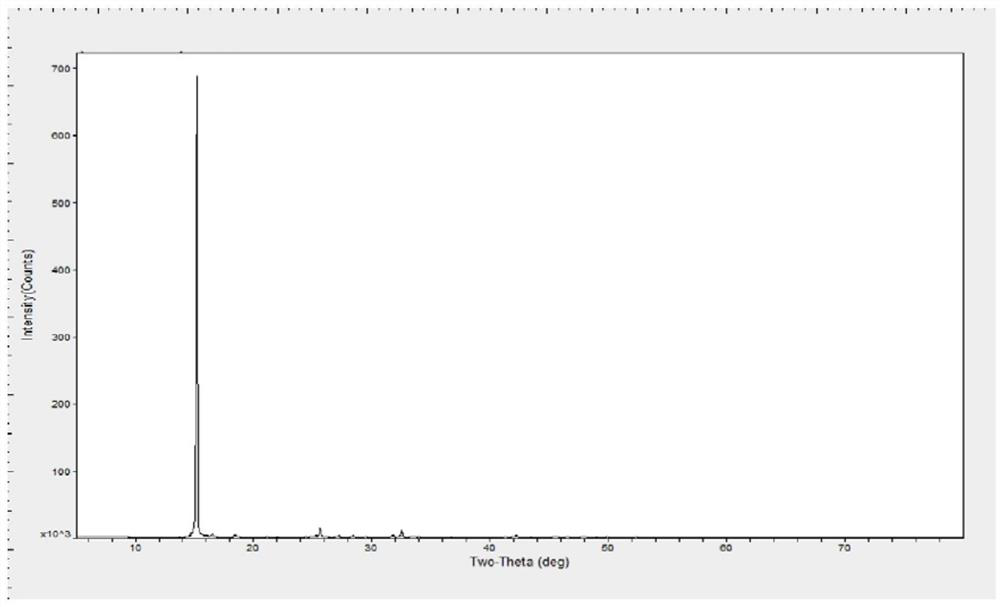

[0033]Preparation of high-quality 1,3-cyclohexanedione product: Add 300kg of water into a 3000L enamel crystallization kettle, add 60kg of high-quality 1,3-cyclohexanedione crystal seeds under stirring conditions, and prepare the high-quality crystal seeds The method is consistent with the preparation method of high-quality seed crystals in Example 1, and the temperature is controlled at 5-10 ° C; at the same time, 1500 kg of hydrogenation reaction solution and 450 kg of industrial hydrochloric acid with a concentration of 31% are pumped into the crystallization kettle, the feeding time is controlled at 2 hours, and the temperature is controlled At 5-10°C. After the reaction is completed, when the temperature is lowered to -5 ~ 0°C, the feed liquid enters the centrifuge to dry, and after drying, the material is discharged into the dryer, and the material is discharged after drying to obtain a white powder crystal with a moisture content of about 0.30%. The purity is 99.96%, th...

experiment example 3

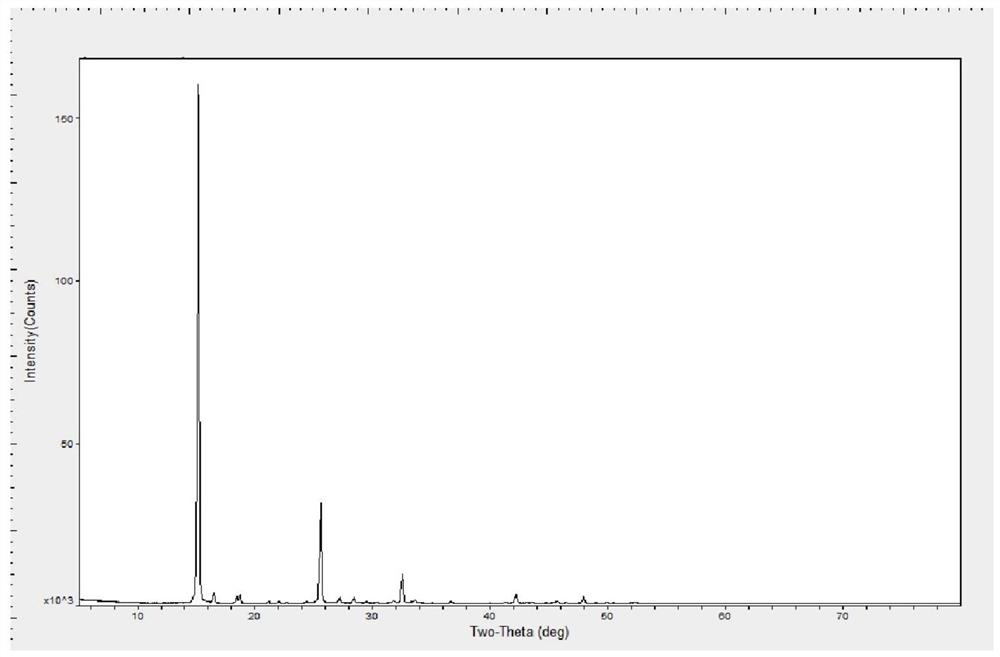

[0035] Preparation of high-quality 1,3-cyclohexanedione product: Add 300kg of water into a 3000L enamel crystallization kettle, and leave 50kg of the high-quality 1,3-cyclohexanedione product prepared in Example 2 in the enamel crystallization kettle as For seed crystals, the temperature is controlled at 5-10°C; at the same time, 1500kg of hydrogenation reaction solution and 450kg of 31% industrial hydrochloric acid are pumped into the crystallization tank, the feeding time is controlled at 2h, and the temperature is controlled at 5-10°C. After the reaction is completed, when the temperature is lowered to -5 ~ 0°C, the feed liquid enters the centrifuge to dry, and after drying, the material is discharged into the dryer, and the material is discharged after drying to obtain a white powder crystal with a moisture content of about 0.32%. The purity is 99.94%, the yield is 95.86%, and the inorganic salt content is 0.27%. The obtained product was placed in a constant temperature an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com