Polytetrafluoroethylene for extruded tubes and preparation method of polytetrafluoroethylene

A polytetrafluoroethylene and tetrafluoroethylene technology, applied in the field of organic polymer compounds, can solve the problems of extruded pipe transparency, poor strength, complicated operation, long reaction time, etc., and achieve high resin molecular weight, simple operation, and improved flexibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

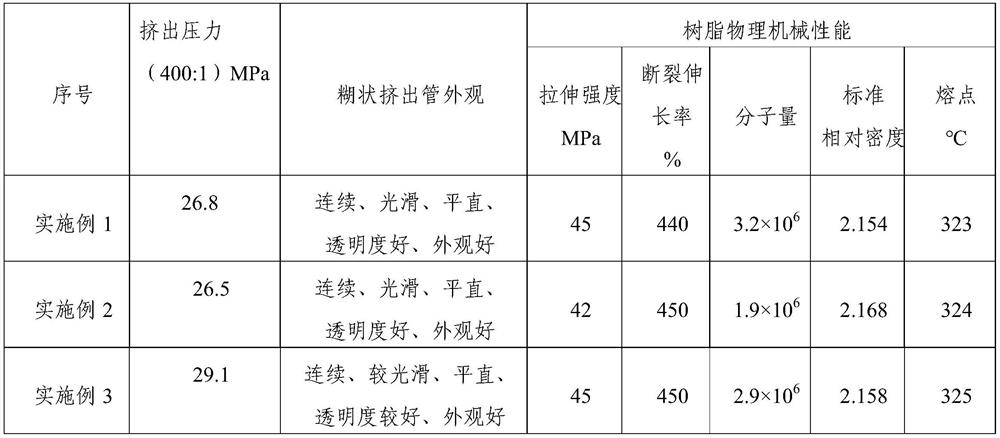

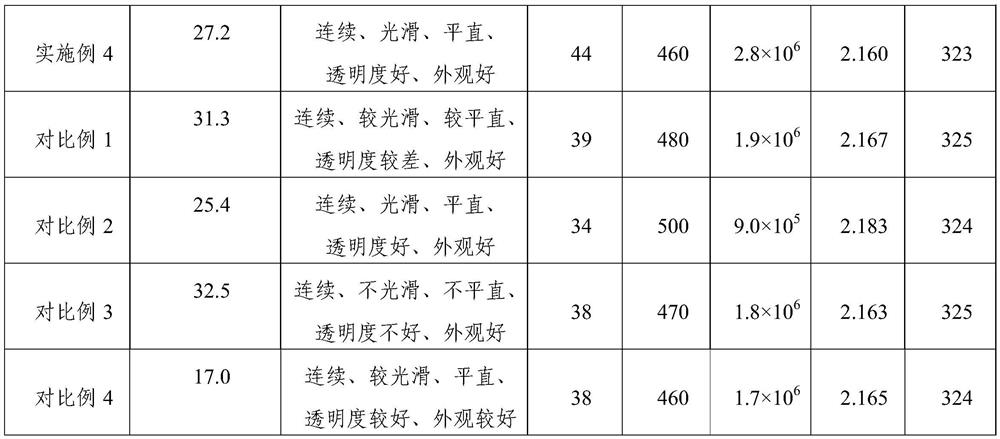

Embodiment 1

[0029] This embodiment relates to a preparation method of polytetrafluoroethylene for pipe extrusion, comprising the following steps:

[0030] 1) Clean the 50L stainless steel reaction kettle, add 32L of deionized water, 8g of ammonium perfluorooctanoate as a dispersant, and 2kg of paraffin, then seal the kettle, evacuate and replace with nitrogen, and analyze the oxygen content. When the oxygen content is less than or equal to 30ppm, it is qualified. Add 55g of modifier A perfluoropropyl vinyl ether (PPVE) at one time through the metering pump, the temperature of the reaction kettle is raised to 74±1°C, the gas phase monomer tetrafluoroethylene is put in, and the pressure in the kettle is 1.6MPa, and the initiator is added Oxidize 25g of succinic acid (pure), and start the polymerization reaction in the early stage. During the reaction, the pressure in the kettle is maintained at 1.6MPa, and the temperature is 75-80°C. According to the change of the polymerization speed, the ...

Embodiment 2

[0033] A method for preparing a polytetrafluoroethylene dispersed resin differs from Example 1 only in that the polymerization pressure in the early stage is 1.3 MPa, and the polymerization pressure in the later stage is 2.3 MPa. In this way, polytetrafluoroethylene dispersion resin was prepared.

Embodiment 3

[0035] A method for preparing a polytetrafluoroethylene dispersed resin differs from Example 1 only in that the polymerization pressure in the early stage is 1.8 MPa, and the polymerization pressure in the later stage is 2.8 MPa. In this way, polytetrafluoroethylene dispersion resin was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com